Sludge discharge system

A technology of sludge discharge pipe and baffle, which is applied in the feeding/discharging device, chemical instrument and method, separation method, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

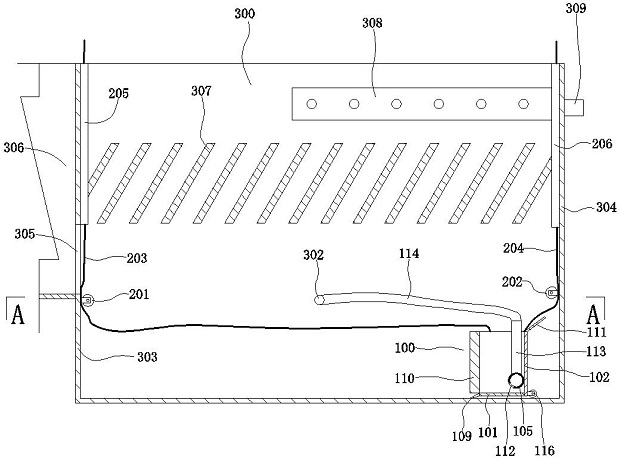

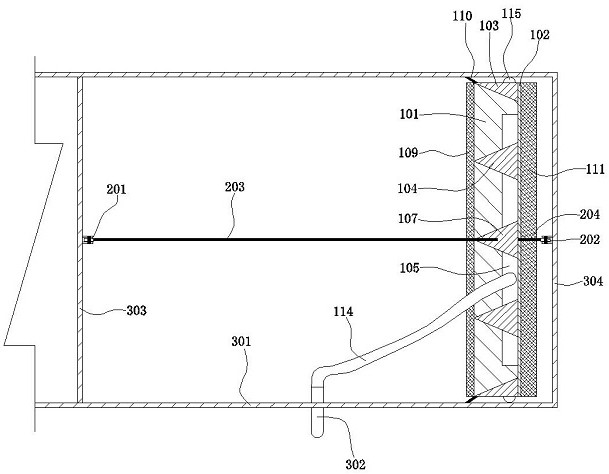

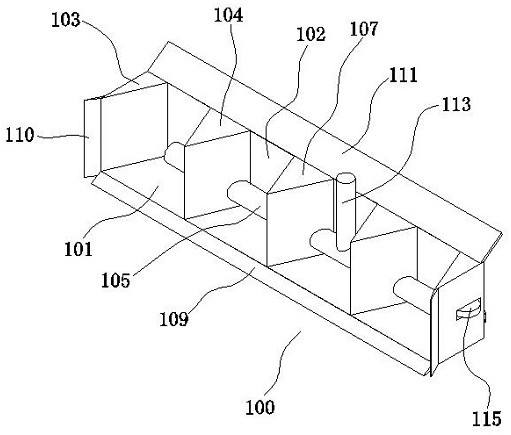

[0012] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 —4.

[0013] A mud discharge system includes a driving mechanism and a mud discharge mechanism 100 . The mud discharge mechanism 100 includes a bottom plate 101 , a back plate 102 , a side plate 103 , a partition 104 and a mud discharge pipe 105 . One side of the bottom plate 101 is fixedly connected to one side of the back plate 102 , and two adjacent side surfaces of the bottom plate 101 and the back plate 102 are fixedly connected to two sides of two side plates 103 at the same time. A partition 104 is arranged between the two side panels 103, and the partition 104 is fixedly connected to the bottom panel 101 and the back panel 102 at the same time, and the partition 104 and the side panels 103 are triangular prisms. A “eight”-shaped opening 106 is formed between the side plate 103 and the partition 104 , and a “eight”-shaped openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com