Anti-blocking filtering pipeline

A pipeline and anti-blocking technology, applied in the pipeline field, can solve problems such as affecting the normal discharge of wastewater, poor overall effect, and pipeline blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

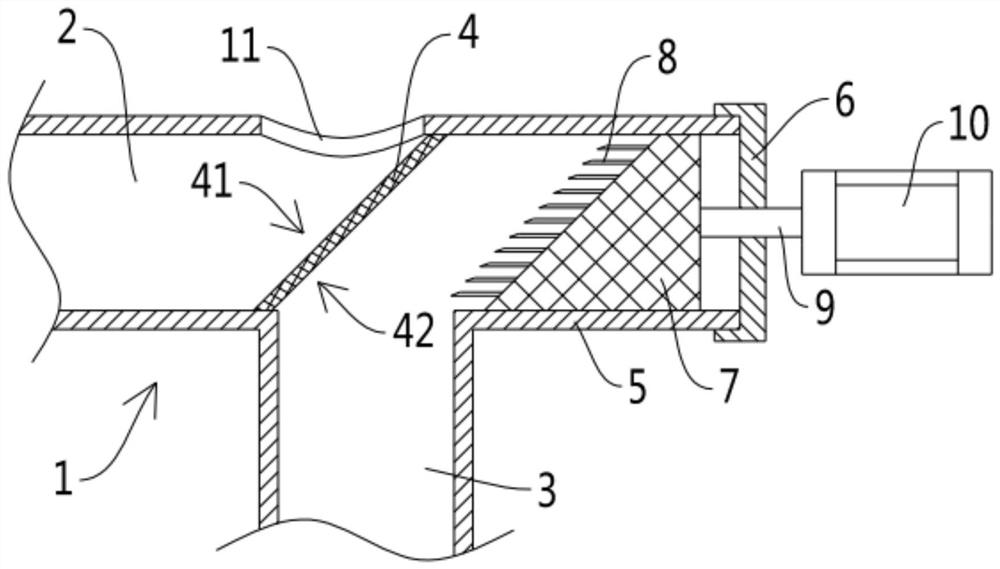

[0021] see figure 1 As shown, an anti-blocking filter pipeline involved in this embodiment includes an L-shaped elbow body 1, the elbow body 1 is composed of a horizontal pipe body 2 extending horizontally and a vertical pipe body 3 extending vertically up and down. Composition, the elbow body 1 is provided with a filter screen 4 that blocks its interior and forms an angle of 45° with the horizontal plane, and the filter screen 4 is arranged at the corner of the horizontal pipe 2 and the vertical pipe 3 At the position, the filter screen 4 has a water-facing surface 41 and a back-water surface 42, and the horizontal pipe body 2 is provided with a discharge port 11 located directly above the water-facing surface 41, and the vertical pipe body 3 is located directly on the back-water surface 42. below;

[0022] Extended on the transverse pipe body 2 is a branch pipe 5 on the same straight line, the branch pipe 5 is arranged on the side of the backwater surface 42 of the filter s...

Embodiment 2

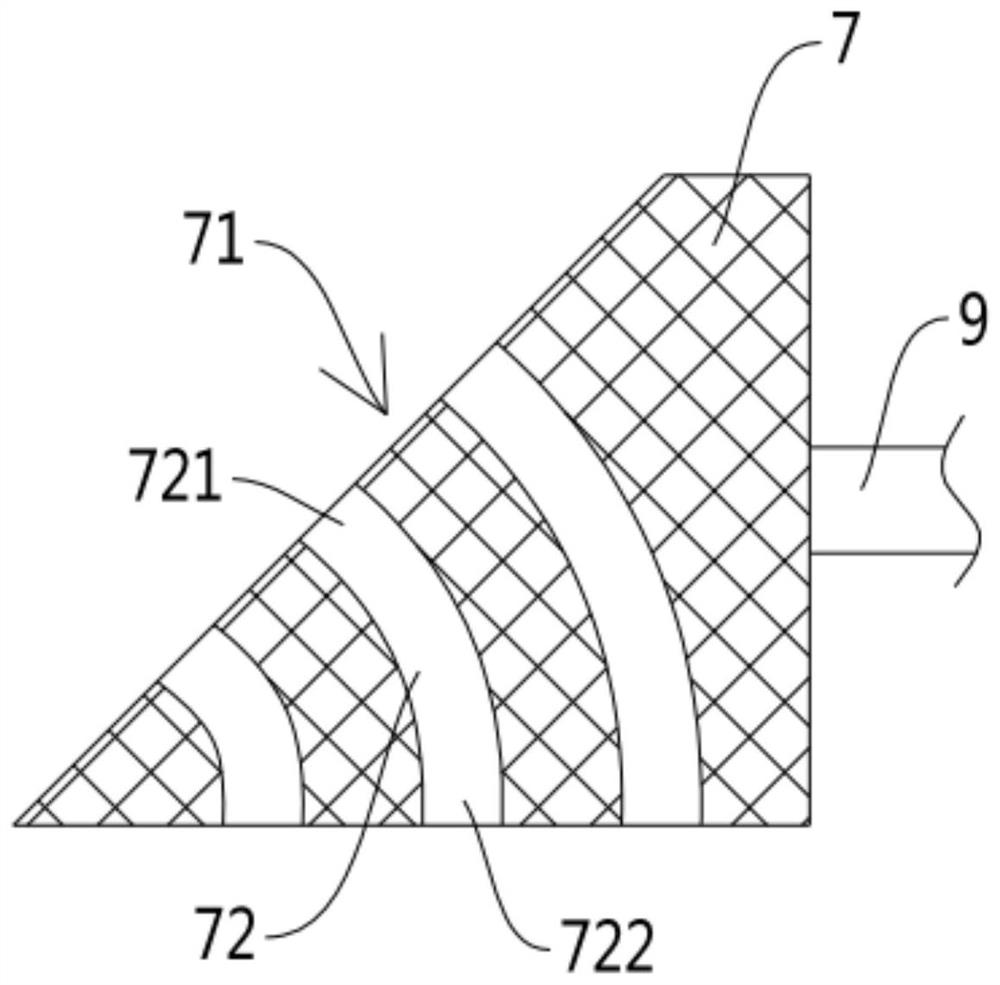

[0030] see figure 1 and figure 2 As shown, a kind of anti-blocking filter pipeline involved in this embodiment is further set on the basis of Embodiment 1, a plurality of water guide channels 72 are opened on the movable plug 7, and the water guide channels 72 have The water guide inlet 721 and the water guide outlet 722, the water guide inlet 721 is arranged on the plug end face 71, and the water guide outlet 722 is arranged at the bottom of the movable plug 7.

[0031] In Embodiment 1, when the movable plug 7 is close to the filter screen plate 4, and the cleaning needle 8 is inserted into the mesh on the filter screen plate 4, the waste water is blocked, and the flow rate is greatly reduced instantaneously, which is easy to cause backflow at the source end of the waste water. In this embodiment, the water guide channel 72 connecting the plug end surface 71 and the bottom of the movable plug 7 is set on the movable plug 7, so that when the movable plug 7 is close to the fi...

Embodiment 3

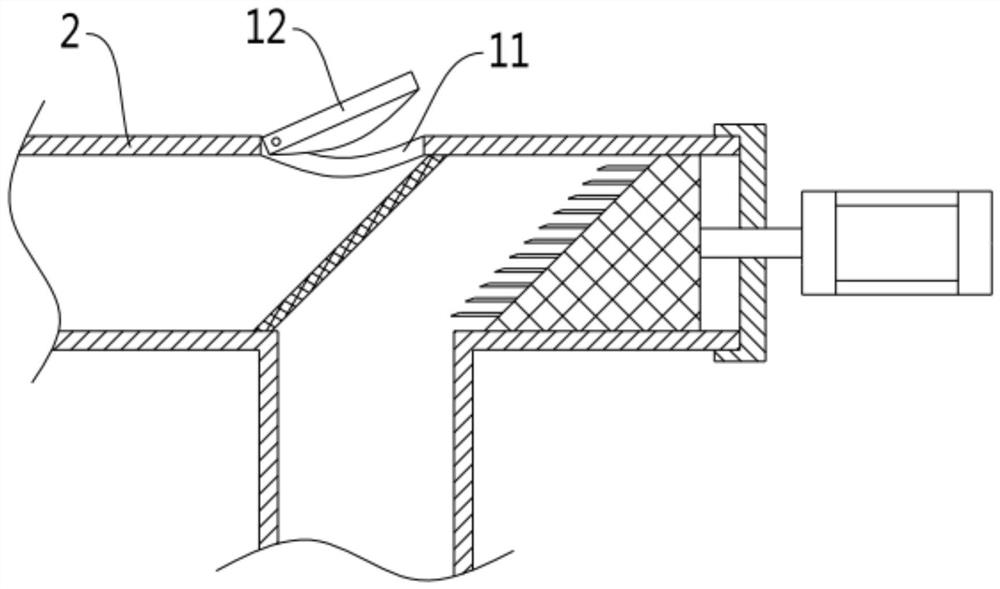

[0033] see Figures 1 to 3 As shown, the anti-clogging filter pipeline involved in this embodiment, on the basis of Embodiments 1 and 2, is further provided that the discharge port 11 is hinged with a discharge end cover 12 .

[0034] Through the setting of the discharge end cover 12, it is not only used as a cover for the discharge port 11, but also makes it impossible to quickly squeeze out the discharge port 11 when the amount of garbage concentrated on the water-facing surface 41 of the filter screen plate 4 is insufficient, thus achieving moderate compression and floating The role of garbage is to facilitate subsequent collection and treatment after discharge.

[0035] The anti-clogging filter pipe involved in the present invention completes the filtering operation of the incoming waste water by setting an inclined filter screen in the main body of the elbow, and the filtered floating garbage is pushed along the filter screen and is discharged from the discharge port. Pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com