Stirring device for vermicelli processing

A technology of stirring device and vermicelli, which is applied to mixers with rotary stirring devices, accessories of mixers, transportation and packaging, etc., can solve the problems of low efficiency and labor consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

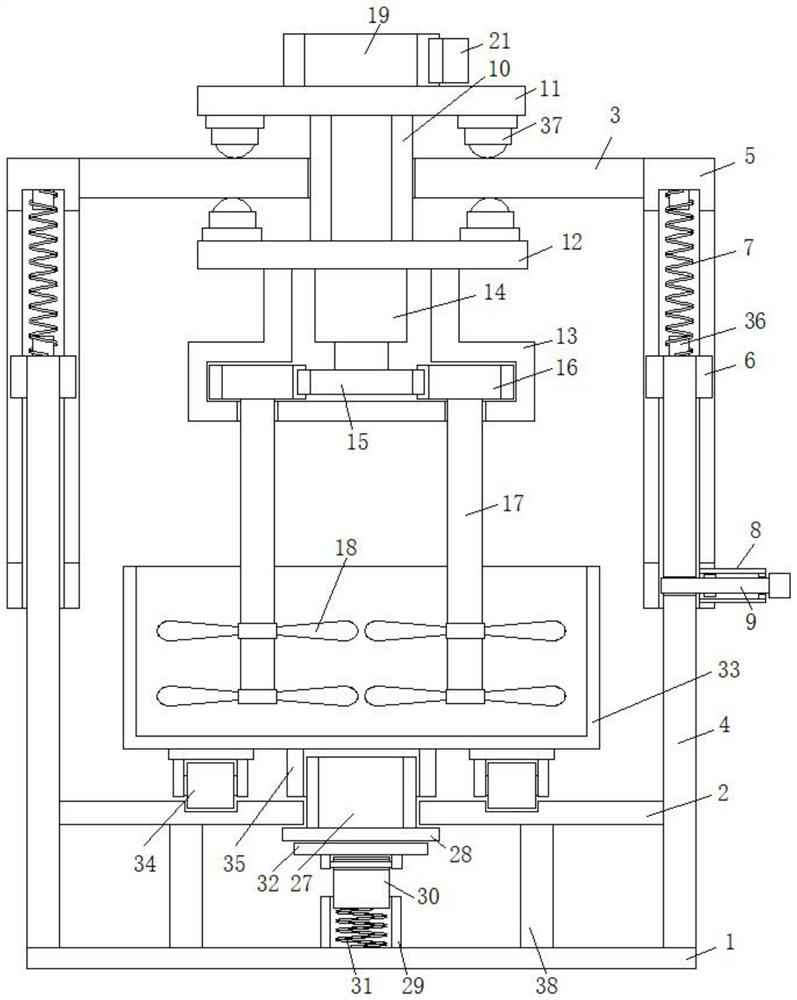

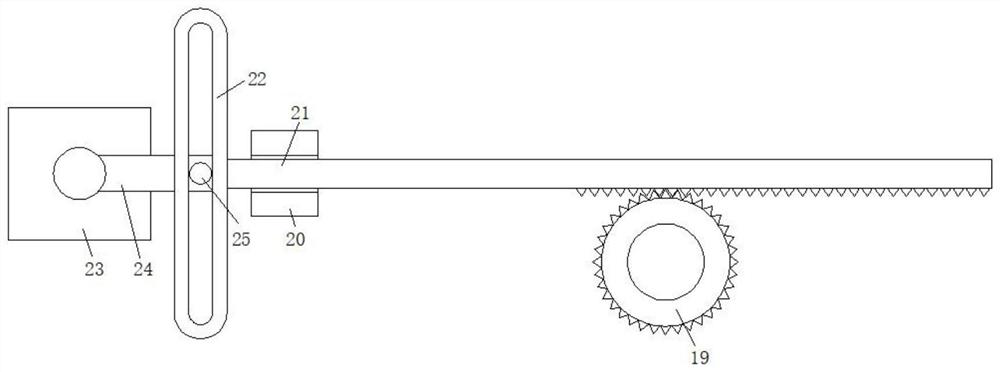

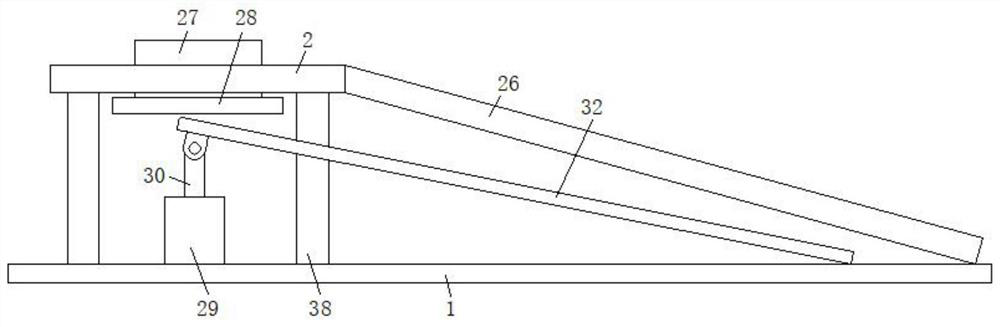

[0027] refer to Figure 1-4 , a mixing device for vermicelli processing, comprising a base 1, a placing platform 2 and a top mounting plate 3 are arranged vertically above the base 1, the top mounting plate 3 is located on the top of the placing platform 2, and the top sides of the placing platform 2 are fixedly connected Track column 4 is arranged, and the top sliding sleeve of track column 4 is provided with track sliding sleeve 5, and one side of track sliding sleeve 5 is fixedly connected with top mounting plate 3, and the both sides of track sliding sleeve 5 are provided with sliding holes, and the rail column 4 The two sides of the top are fixedly connected with the limit slide 6, and one end of the limit slide 6 is slidably connected in the slide hole, and an auxiliary support spring 7 is arranged between the top side of the track column 4 and the top inner wall of the track slide sleeve 5, and the track slide sleeve One side of the bottom end of 5 is provided with a si...

Embodiment 2

[0030] like Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the top side of the track column 4 and the top inner wall of the track sliding sleeve 5 are fixedly installed with a spring positioning column 36, and the two ends of the auxiliary support spring 7 are sleeved respectively. On the outside of one end of the spring positioning post 36 .

[0031] In this embodiment, the setting of the spring positioning column 36 makes the auxiliary support spring 7 more stable during the stretching process, and the auxiliary support spring 7 is more labor-saving when the stirring shaft 17 needs to leave the mixing barrel 33 after the stirring is completed, which greatly improves Manpower is saved.

Embodiment 3

[0033] like Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, both sides of the placing platform 2 are fixedly connected to the track columns 4 respectively, and a support column 38 is fixedly connected between the bottom side of the placing platform 2 and the base 1 .

[0034] In this embodiment, the placing table 2 can stably support the mixing bucket 33 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com