Magnetic particle inspection, cleaning, drying and oiling integrated device

A magnetic particle flaw detection, integrated technology, applied in the direction of drying gas arrangement, device for coating liquid on the surface, drying, etc., can solve the problems of inconvenient operation, easy displacement, troublesome manual operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

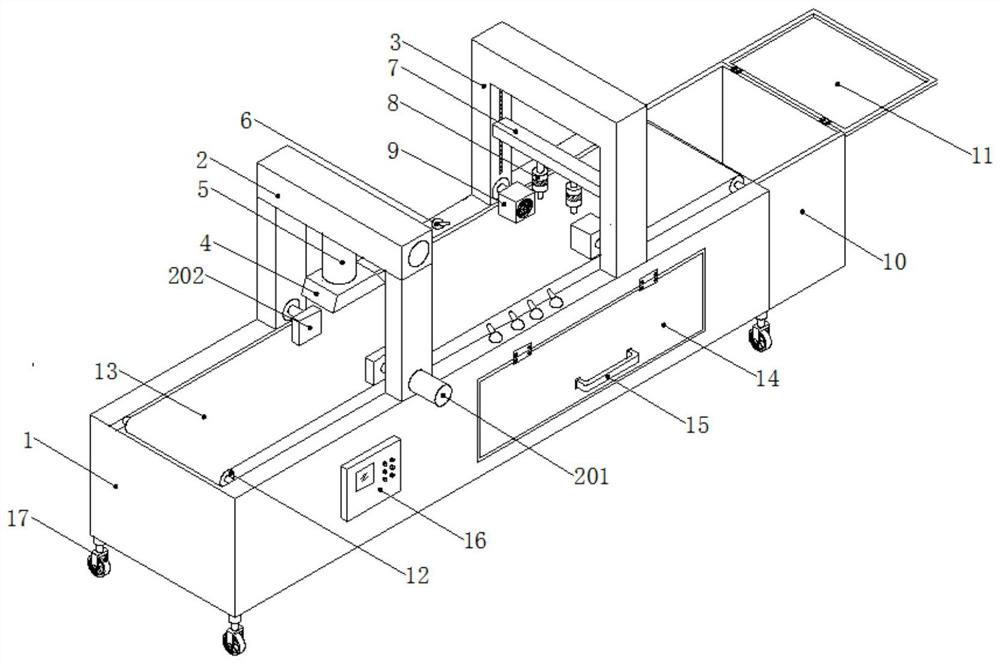

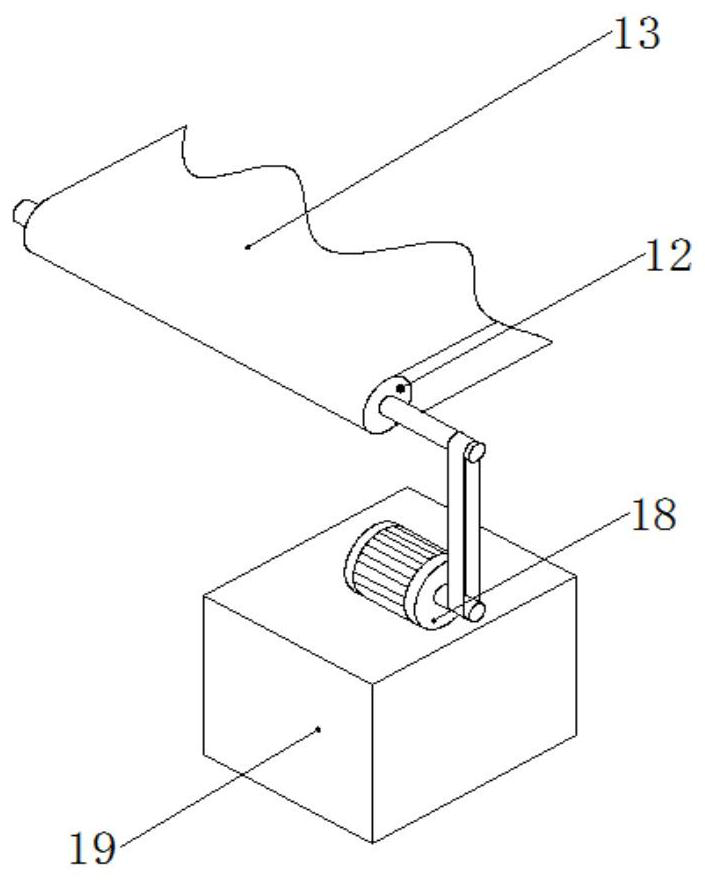

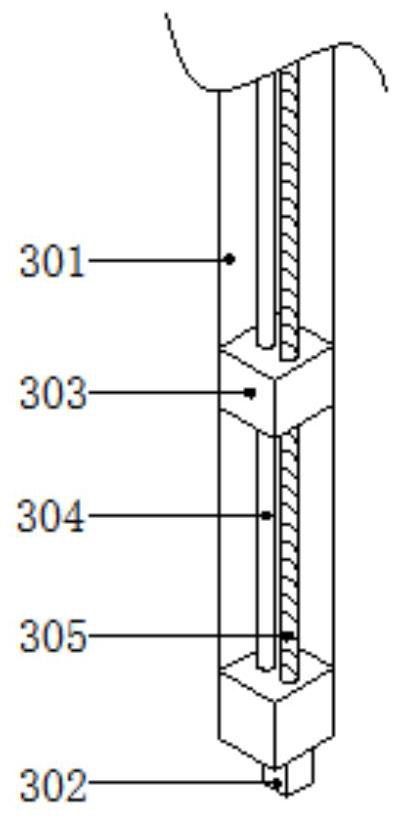

[0025] Example: such as Figure 1-4 As shown, a magnetic particle flaw detection, cleaning, drying and oiling integrated device of the present invention includes a base 1, a gantry 2 is fixedly installed on the top of the base 1, a telescopic rod 5 is fixedly installed on the inner wall of the top of the gantry 2, and the bottom of the telescopic rod 5 is arranged There is a magnetic particle flaw detection machine 4, a water spray head 6 is provided on one side of the gantry frame 2, and several groups of water spray heads 6 are arranged, and a pair of support columns 3 are fixedly installed on one side of the water spray head 6, and a slide is provided on the inner side of the support column 3. Groove 301, one side of the chute 301 is provided with a fixed frame 7, the bottom of the fixed frame 7 is fixedly installed with an oiler 8, one side of the bottom of the support column 3 is fixedly installed with a dryer 9, the top of the base 1 is provided with a roller 12, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com