Modular size-adjustable prefabricated stair mold

A technology for size adjustment and stair mould, applied in the direction of molds, manufacturing tools, mold fixtures, etc., can solve the problems of waste of resources, low mold turnover rate and reuse rate, high amortization cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

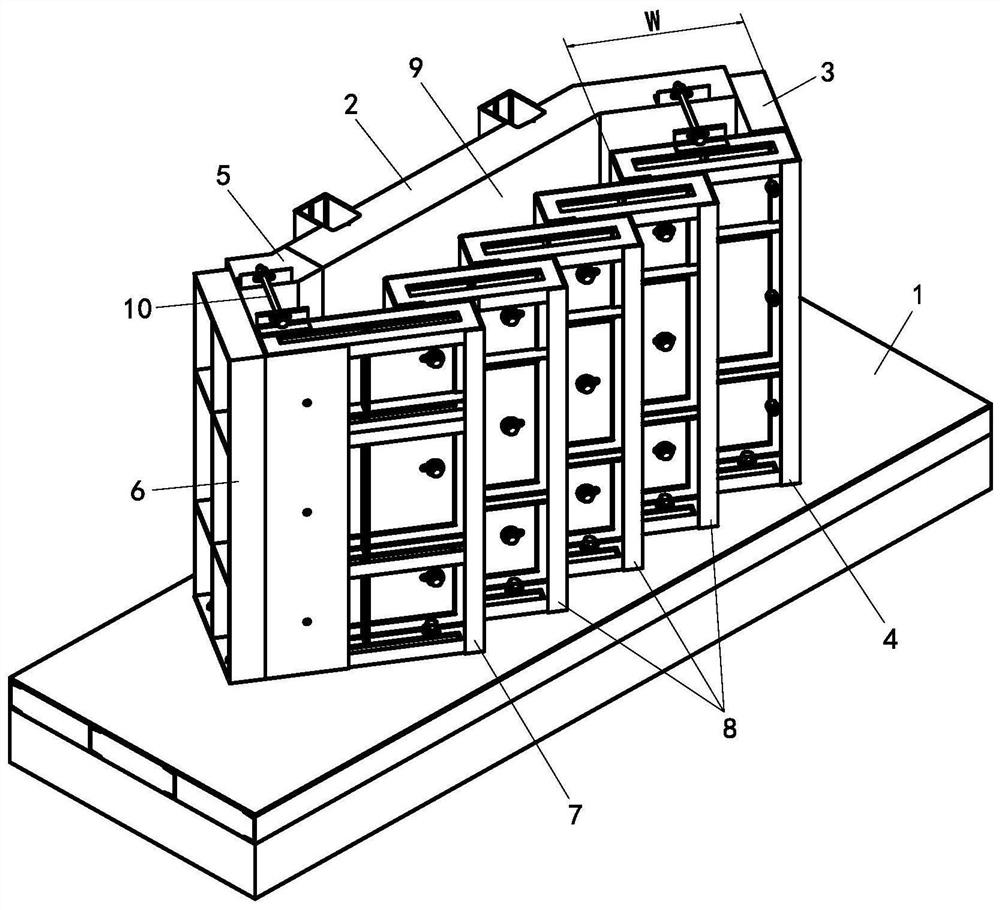

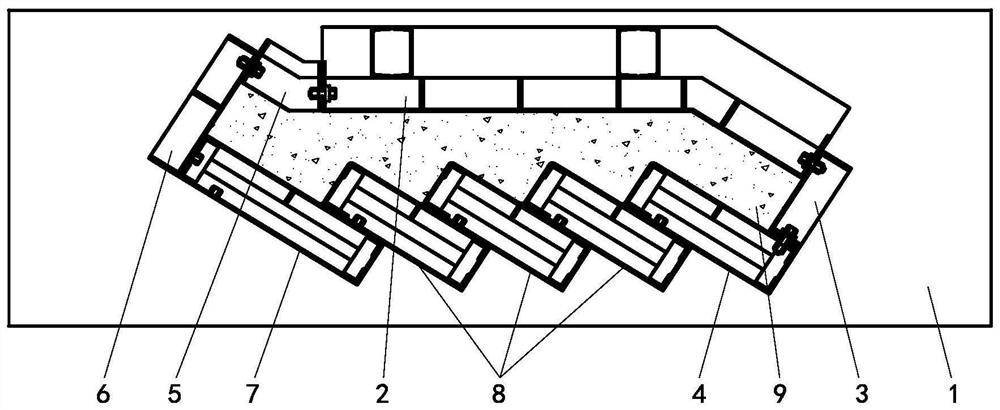

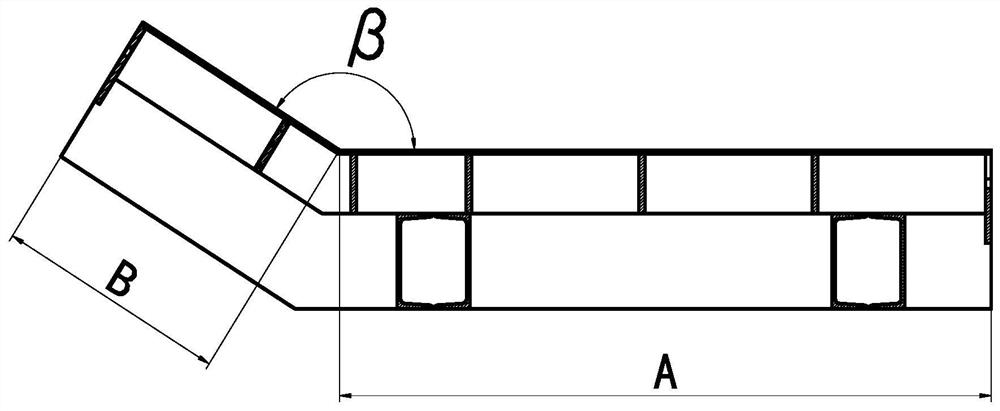

[0028] For specific implementation, follow the steps below for construction

[0029] Step 1. Lay out the wires on the base platform 1 according to the dimensions of the stairs to be prefabricated;

[0030] Step 2. Fix the ladder back main template 2 on the top surface of the base platform 1 through screws 15 and nuts 16 according to the setting out;

[0031] Step 3. Fix the ladder back adjustment template 5 on the top surface of the base platform 1 through screws 15 and nuts 16 according to the setting out; and connect with the ladder back main template 2;

[0032] Step 4. Fix a group of step modules 8 on the top surface of the base platform 1 through screws 15 and nuts 16 according to the setting out; and connect each step module 8 as a whole through screws 15 and nuts 16;

[0033] Step 5. Fix the upper platform formwork 4 and the lower platform formwork 7 on the top surface of the base platform 1 through screws 15 and nuts 16 according to the setting-out; The two ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com