Quantitative filling device for beverage processing

A filling device and beverage technology, applied in packaging, liquid materials, transportation and packaging, etc., can solve problems such as measurement errors, increased production costs, and impact on quantitative filling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

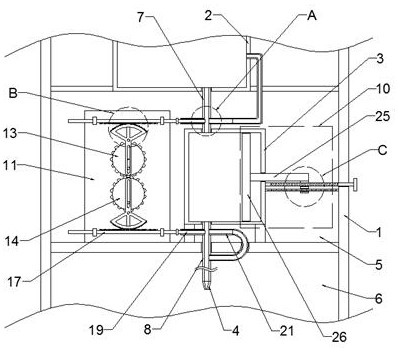

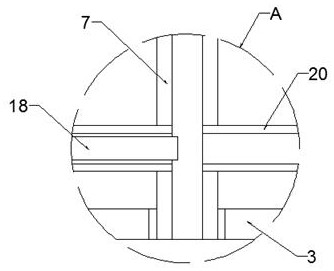

[0027]Embodiment: When the present invention is used, first adjust the real-time capacity of the measuring cylinder 3 according to the capacity demand of a single filling, that is, adjust through the capacity regulating mechanism 10, and rotate the feed handwheel at the end of the adjusting rod 22 to control the movable block 24 along the scale The rod body of the rod 23 is displaced horizontally, the movable block 24 moves to drive the push rod 25, and the push rod 25 synchronously drives the pressure plate 26 to move horizontally inside the measuring cylinder 3, and the scale on the scale rod 23 can reflect the real-time capacity inside the current measuring cylinder 3 in real time, finally realizing Adjustment and control of the capacity of the measuring cylinder 3.

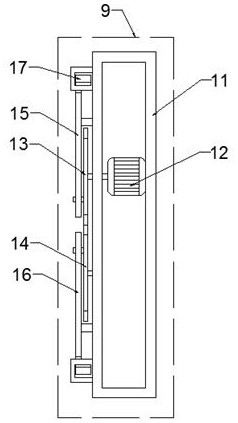

[0028] During the filling operation, the flow control mechanism 9 drives the servo motor 12 to drive the first toothed disc 13 to rotate, the first toothed disc 13 rotates to drive the second toothed disc 14, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com