Water conservancy project joint-crossing post-installation built-in water stop assembly structure and construction method

A technology for water conservancy projects and assembly structures, which is applied in water conservancy projects, sea area projects, infrastructure projects, etc., and can solve problems such as impossibility and water stop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

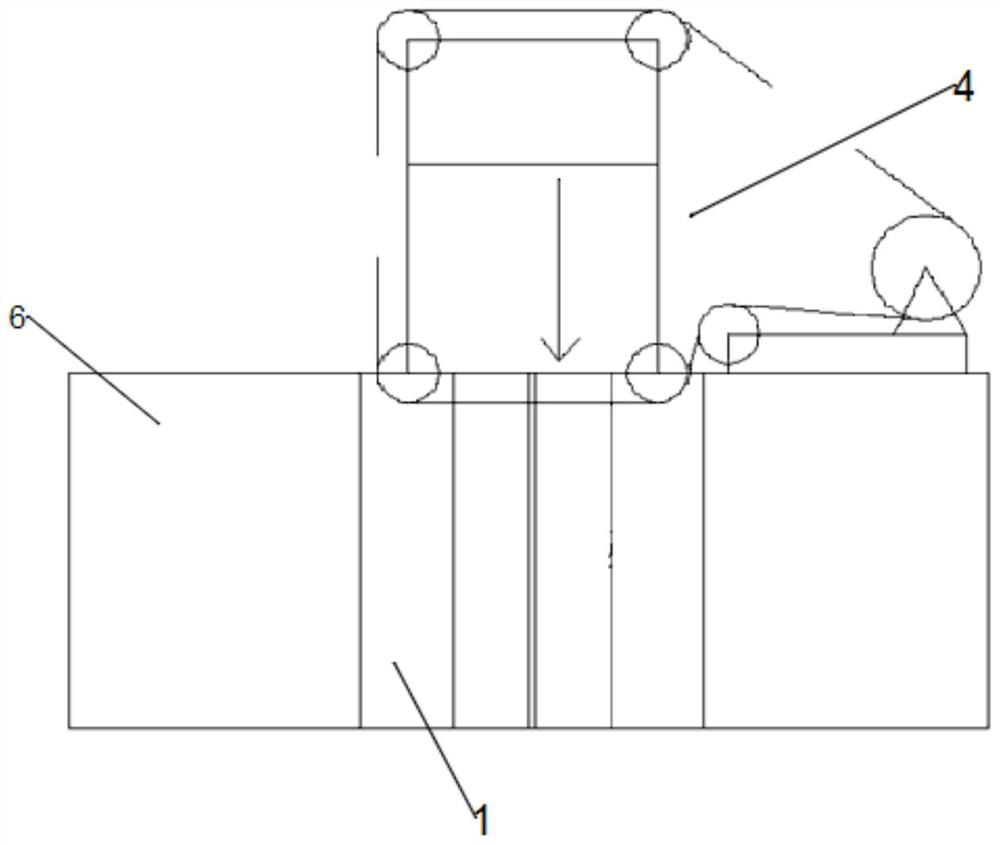

[0035]Such asfigure 1 orimage 3 As shown, the construction method, construction method, construction scheme and working principle of the water conservancy engineering span rear rear rear, the construction scheme is determined before the construction, then determine the depth of the construction seam 5, then open two sides of the construction seam 5 The depth of the road is greater than the grouting hole of the depth of the construction seam 1; then set the rope saw above the grout hole 1, and the rear rope saw 4 cutting portion can be adjusted below the construction seam 5 below, the rope saw in the present invention 4 Use a concrete cutting rope saw of the beaded diameter of 8 mm to 11 mm; after the rope saw 4, the construction of the slot 2 is performed, and the width is larger than the slot 2 of the water tape 3 width and the depth of the groove 2 is larger than the construction seam 5. Depth; After the tank 2 is completed, it is necessary to clean the cutting groove 2 and the gr...

Embodiment 2

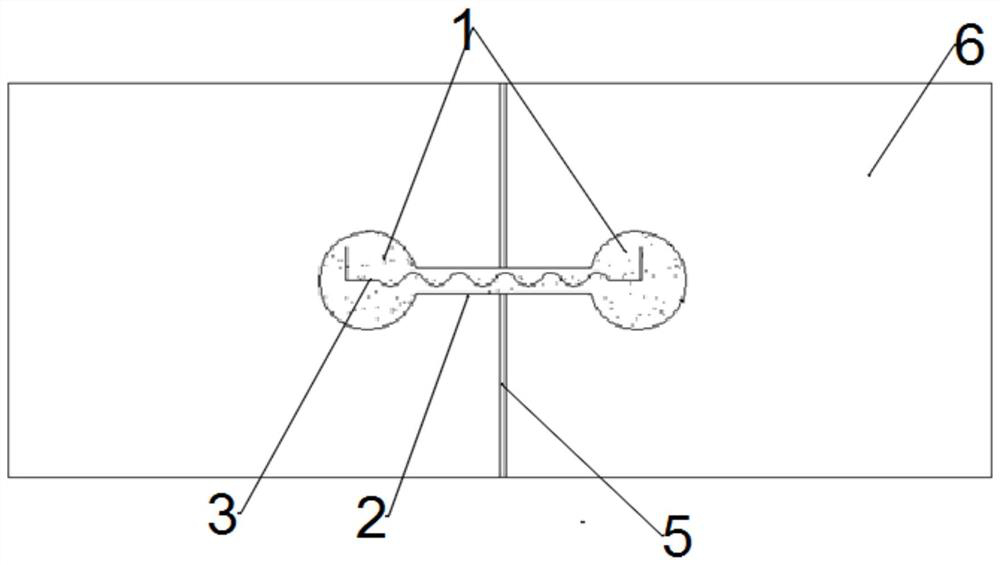

[0037]Such asFigure 1 - Figure 3As shown, a water conservancy engineering span rear mounting structure includes a grouting hole 1, a slit 2, a water tape 3, and two of the grouting holes 1 are opened on both sides of the construction seam 5, and About the construction seam 5 symmetry;

[0038]The slot 2 is opened perpendicular to the construction seam 5, and the two ends are connected to a grouting hole 1, and the depth of the grouting hole 1 is greater than the depth of the construction seam 5;

[0039]After the two, the grouting holes 1 and the slot 2 are connected to the concrete structural 6, which is located below the construction seam 5;

[0040]The tape 3 is mounted in a section. The grouting hole 1 has a pore diameter of 120 to 150 mm.

[0041]The cutting depth is greater than the depth of the construction seam 5.

[0042]The two ends of the water belt 3 are provided with a angle and the middle section is a wave shape; the size of the soil strip 3 is adapted to the size of the section, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com