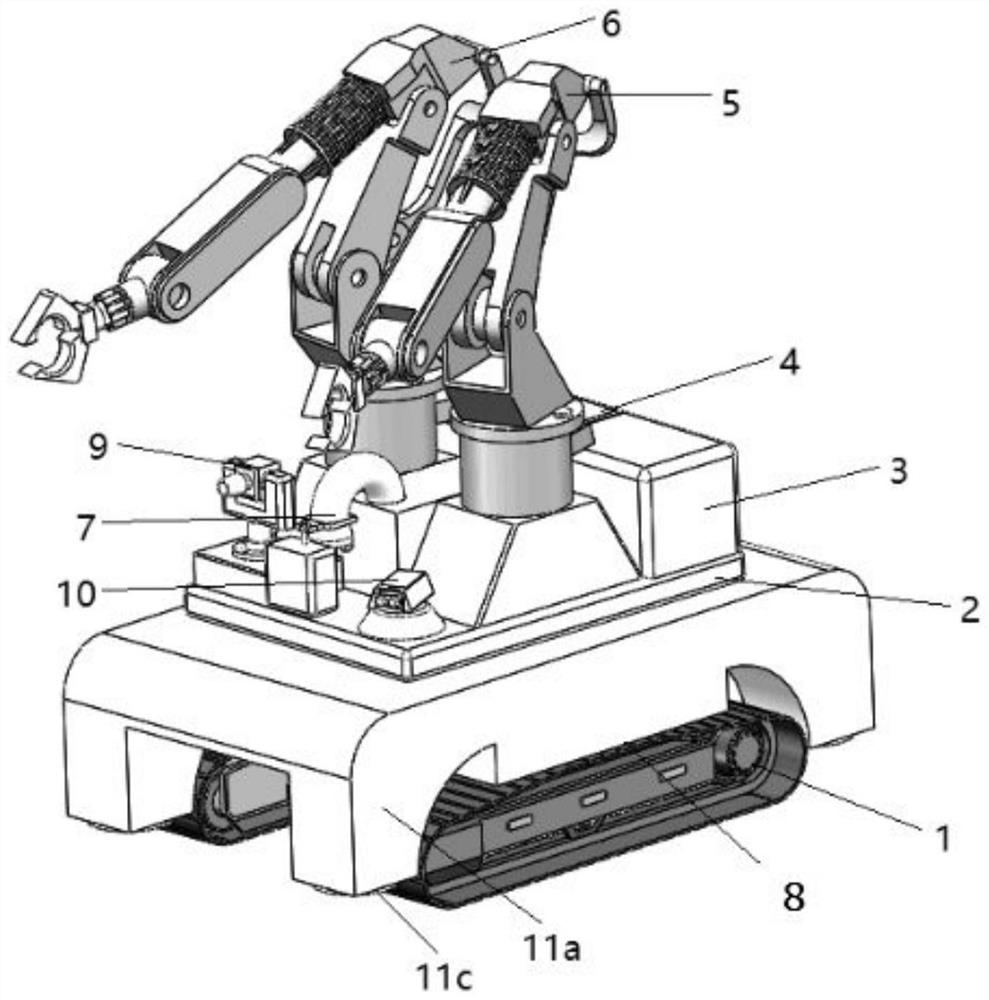

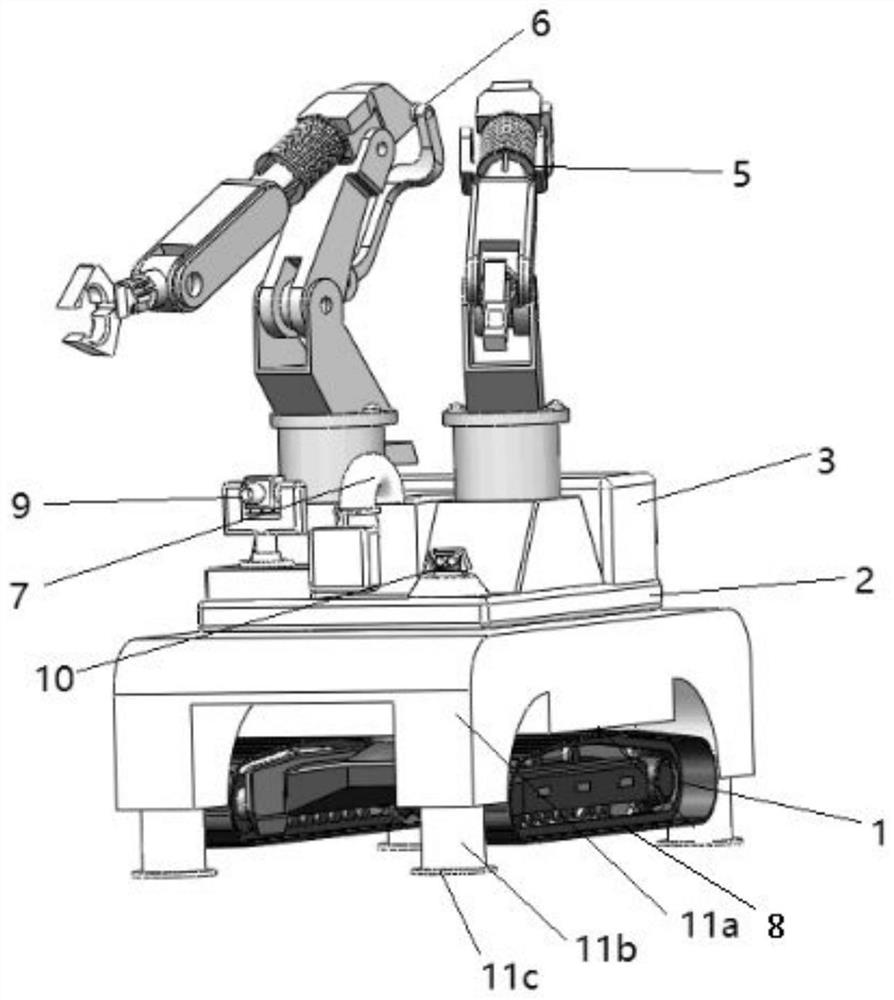

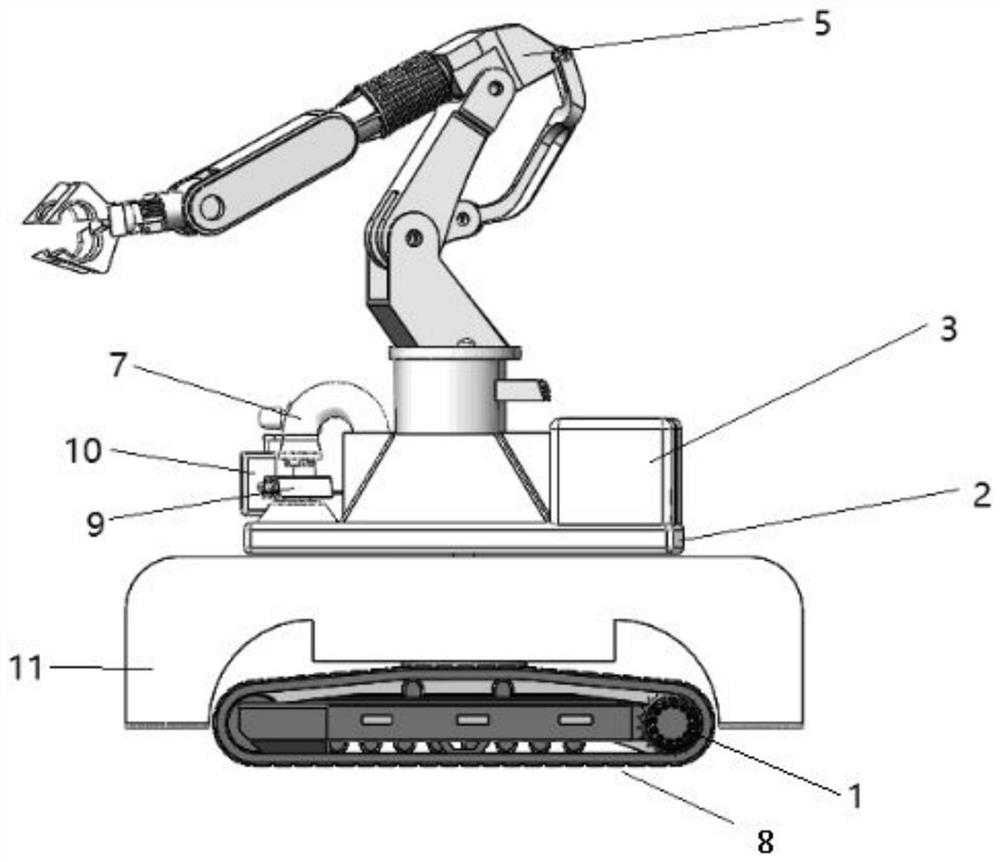

A kind of fire-fighting robot and reaction force control method

A fire-fighting robot and control box technology, applied in the direction of instruments, signal transmission systems, fire rescue, etc., can solve the problems of large body reaction force and backward movement of the body, and achieve the effect of strengthening safety guarantee and enhancing fire extinguishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0080] In order to achieve the above purpose, this embodiment provides a reaction force control method applied to a fire fighting robot, including three stages.

[0081] The first stage: the ground stage based on the hydraulic system and intelligent algorithm, including the following steps:

[0082] ① When the fire-fighting robot reaches the best fire-fighting position, the control box sends a hydraulic column extension signal to the hydraulic motor to make the four hydraulic columns extend out of the shell synchronously and start to touch the ground.

[0083] ②When the four hydraulic columns start to touch the ground, since the ground where the four hydraulic columns are located may not be on the same plane (for example, the first two are on the horizontal plane, and the last two are on the slope, that is, they are at the top of the slope as a whole), that is, when the four hydraulic columns are at the top of the slope. When the ground where the columns are located is not on ...

Embodiment 3

[0095] This embodiment also provides a reaction force control method of a fire fighting robot, including:

[0096] When the fire-fighting robot reaches the best position for extinguishing the fire, the fire-fighting robot stops, and the embedded controller controls the operation of the hydraulic motor and then controls the four hydraulic columns to stretch out. When the hydraulic column does not touch the ground, the hydraulic column extends at the same rate, and the distance is measured by the ultrasonic rangefinder at the top of the four hydraulic columns. When it is judged that one or more hydraulic columns have reached the ground, the embedded control The controller sends a signal to the hydraulic motor according to the control algorithm to change the elongation speed of the hydraulic column to make it tend to stop, so that the fire fighting robot still keeps the original angle unchanged.

[0097] When the hydraulic column starts to touch the ground, since the ground where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com