A built-in waterproof assembly structure and construction method for water conservancy projects after crossing joints

A technology for assembling structures and water conservancy projects, applied in water conservancy projects, sea area projects, infrastructure projects, etc., can solve problems such as inability to carry out and stop water, and achieve the effects of convenient construction, increase or decrease of gripping force, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

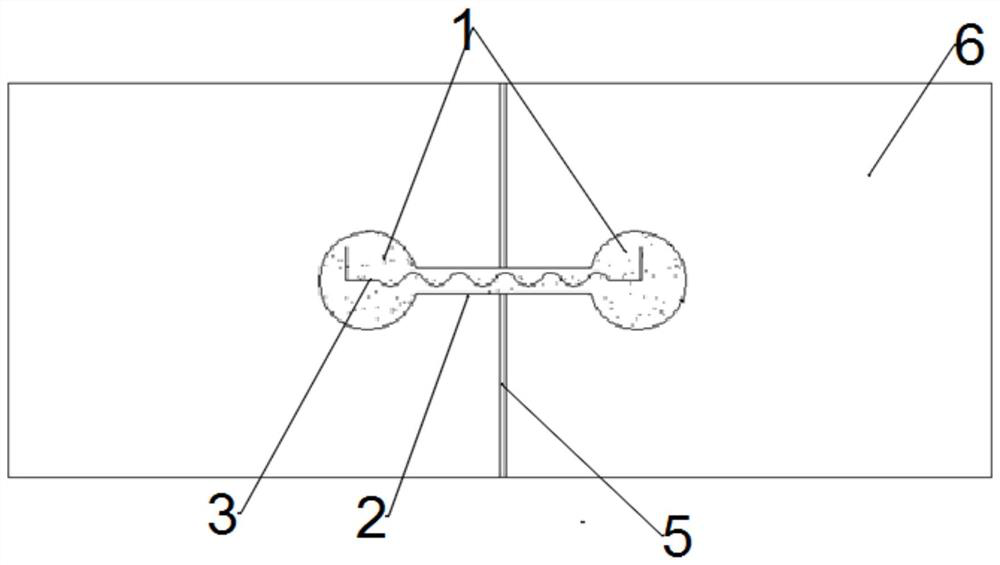

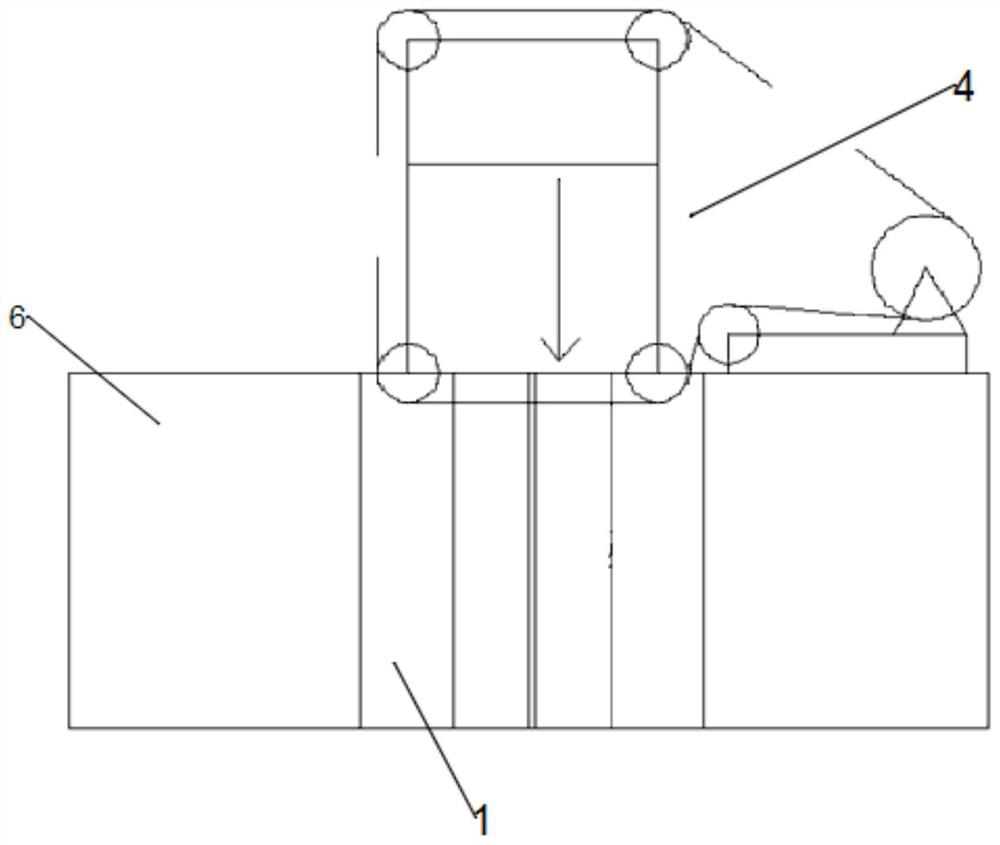

[0035] Such as figure 1 or image 3 As shown in the present invention, a water conservancy project cross-joint post-installation built-in water-stop assembly structure and construction method, the construction plan and working principle are as follows: the depth of the construction joint 5 is determined before construction, and then two symmetrical openings are opened on both sides of the construction joint 5. The grouting hole 1 whose depth is greater than the depth of the construction joint 5; then set up the wire saw above the grouting hole 1, and the cutting part of the wire saw 4 can reach the bottom of the construction joint 5 through the grouting hole 1 after erection. In the present invention, the wire saw 4 Select a concrete cutting wire saw with a beaded diameter of 8mm-11mm; set up the wire saw 4 and carry out the construction of the cutting groove 2, and open a cutting groove 2 with a width greater than the width of the waterstop 3 and the depth of the cutting groo...

Embodiment 2

[0037] Such as Figure 1-Figure 3 As shown, a water conservancy project cross-joint post-installation built-in water-stop assembly structure, the structure includes a grouting hole 1, a groove 2, and a water-stop strip 3, and the two grouting holes 1 are set on both sides of the construction joint 5, and Symmetrical about the construction joint 5;

[0038] The cut groove 2 is set perpendicular to the construction joint 5, and the two ends are respectively connected with a grouting hole 1, and the depth of the grouting hole 1 is greater than the depth of the construction joint 5;

[0039] After the two grouting holes 1 and the cutting grooves 2 are connected, a section is formed in the concrete structure 6, and the section is located below the construction joint 5;

[0040] The waterstop 3 is installed in the section. The diameter of the grouting hole 1 is 120-150 mm.

[0041] The cutting depth of the groove 2 is greater than the depth of the construction joint 5 .

[0042]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com