Lifting device for ocean platform and ocean platform

A technology for offshore platforms and lifting devices, applied in the field of lifting devices and offshore platforms, can solve the problems that the pins are not easy to connect with the holes, and the position accuracy is difficult to guarantee.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

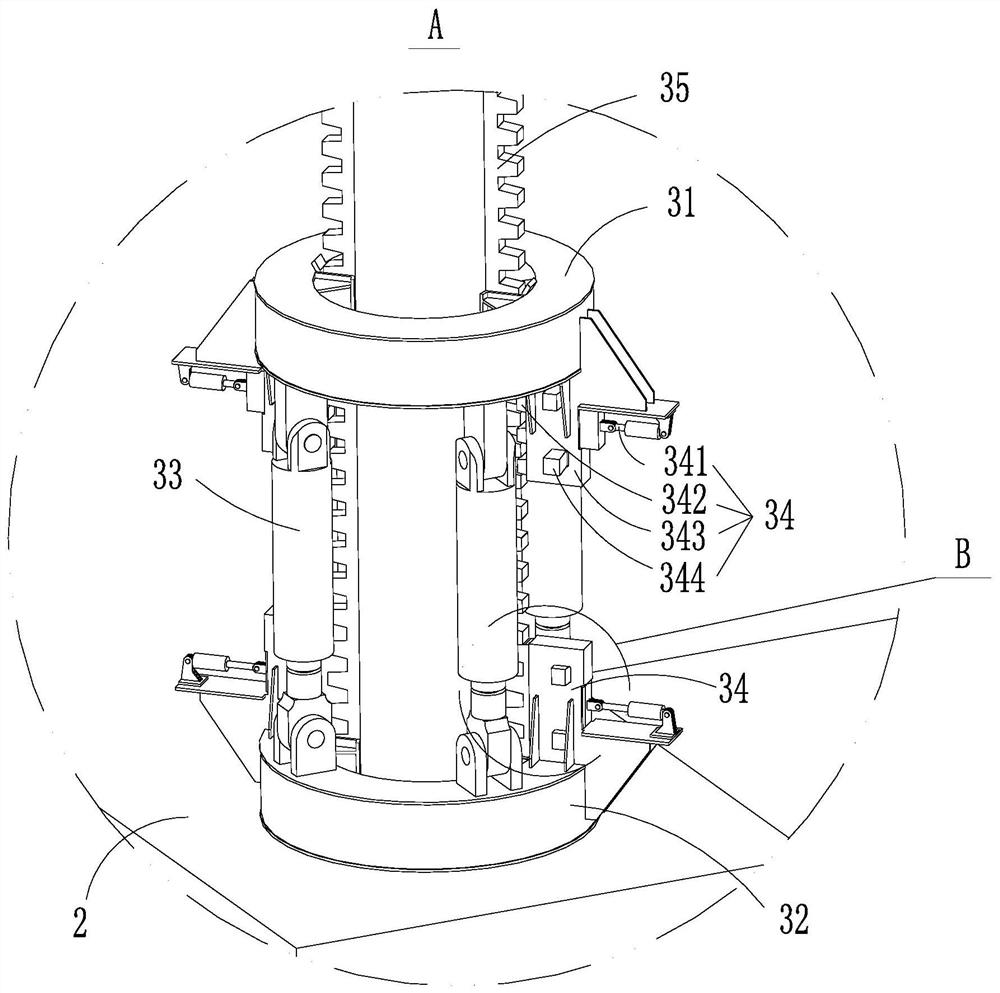

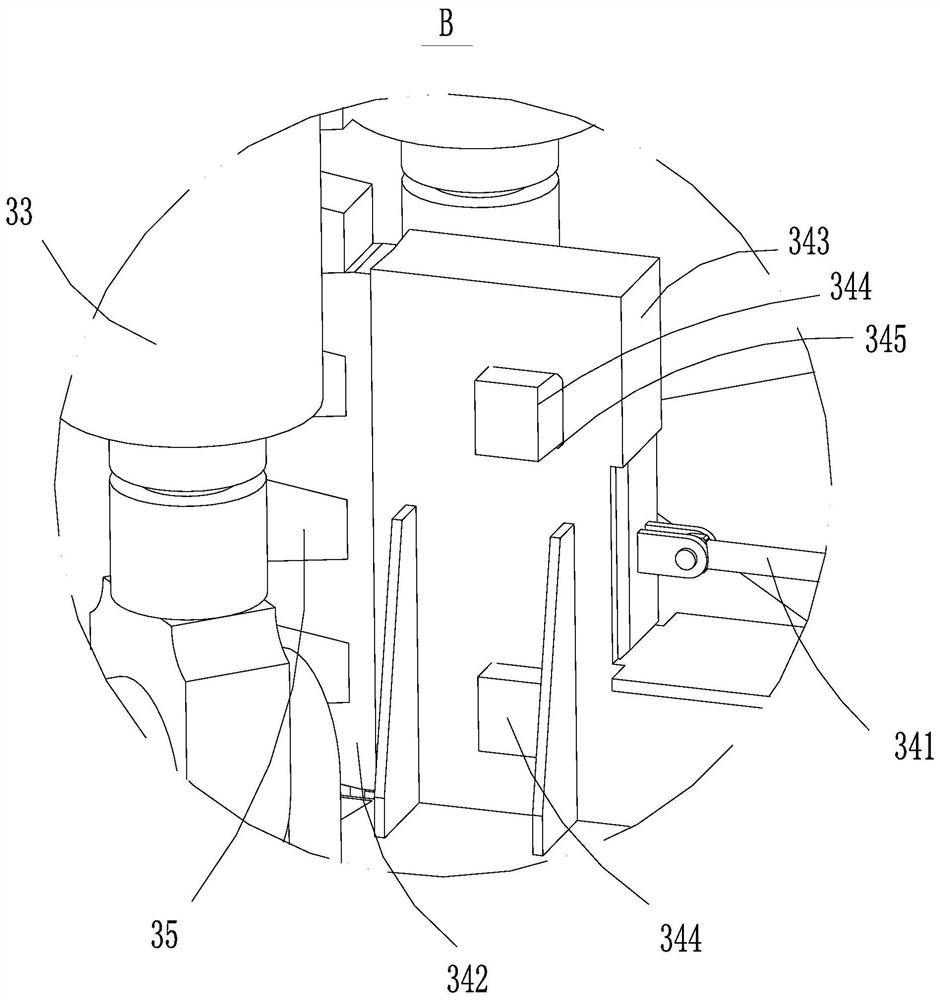

[0037] see Figure 1-Figure 4 , the embodiment of the present invention provides a lifting device 3 for an offshore platform 1 , which includes a first beam 31 , a second beam 32 , a lifting drive 33 , a clamping device 34 and a clamping rack 35 .

[0038] The first beam body 31 is connected to the second beam body 32 through the lifting driver 33, and the length of the lifting driver 33 can be extended or shortened, so that the distance between the first beam body 31 and the second beam body 32 can be increased or decreased. Small. The first beam body 31 is configured as a ring structure, and the first beam body 31 is sheathed on the leg 2 . The second beam body 32 is configured as a ring structure, and the second beam body 32 is sleeved on the leg 2 and fixedly connected to the platform. The number of lifting driving parts 33 is set to be multiple, and the multiple lifting driving parts 33 are evenly distributed in the circumferential direction of the first beam body 31 . ...

Embodiment 2

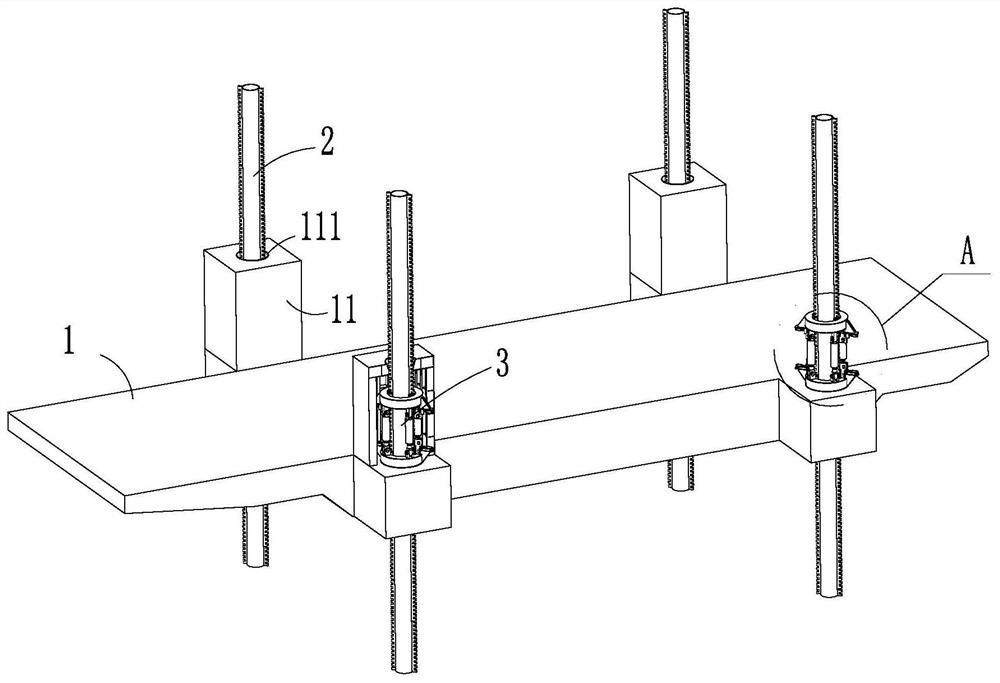

[0059] see figure 1 , the embodiment of the present invention provides an ocean platform, which includes a platform 1 , legs 2 and the lifting device 3 provided in Embodiment 1. The number of legs 2 is at least three. In this embodiment, four legs 2 are provided, and each leg 2 is connected to a lifting device 3 .

[0060] The second beam body 32 of the lifting device 3 is connected to the platform 1 , and the first beam body 31 and the second beam body 32 are sheathed on the leg 2 . The clamping rack 35 is arranged on the pile leg 2 and is fixedly connected with the pile leg 2 . Specifically, the clamping rack 35 is connected to the leg 2 by welding.

[0061] An installation box 11 is provided on the platform 1. The installation box 11 is provided with a through hole 111 for the legs 2 to pass through. An installation cavity is formed on the installation box 11, and the lifting device 3 is placed in the installation cavity. When the lifting driving part 33 is in the retrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com