Locking clamping piece for zipper type wall part

A technology for walls and parts, applied in the field of zipper-type wall parts locking clips, can solve problems such as inability to adapt to construction requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

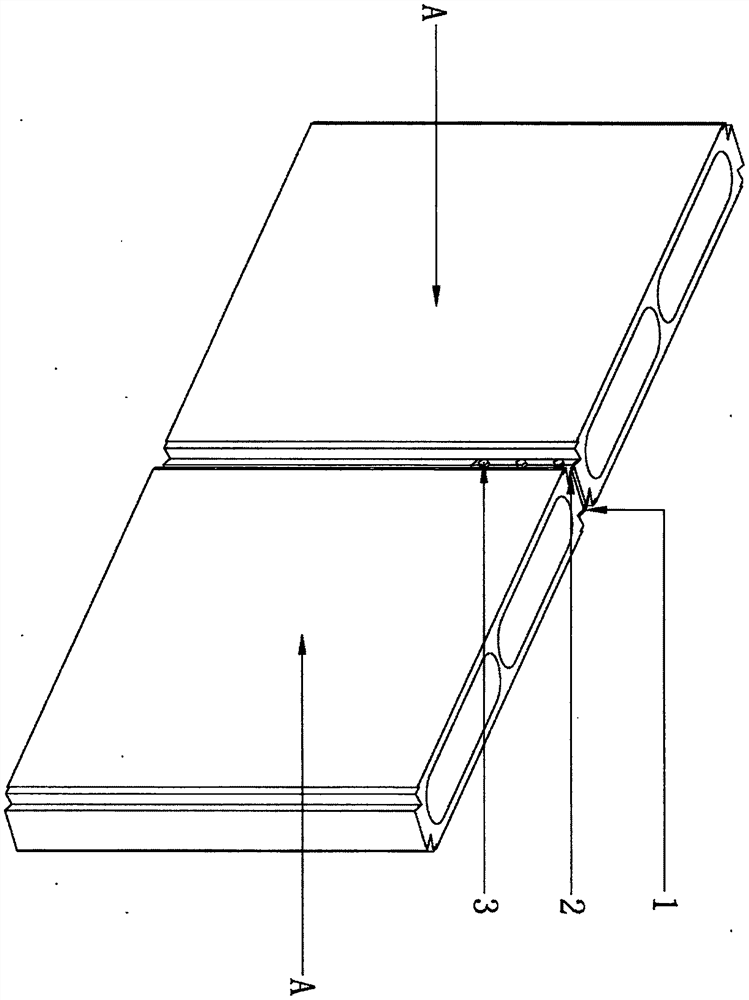

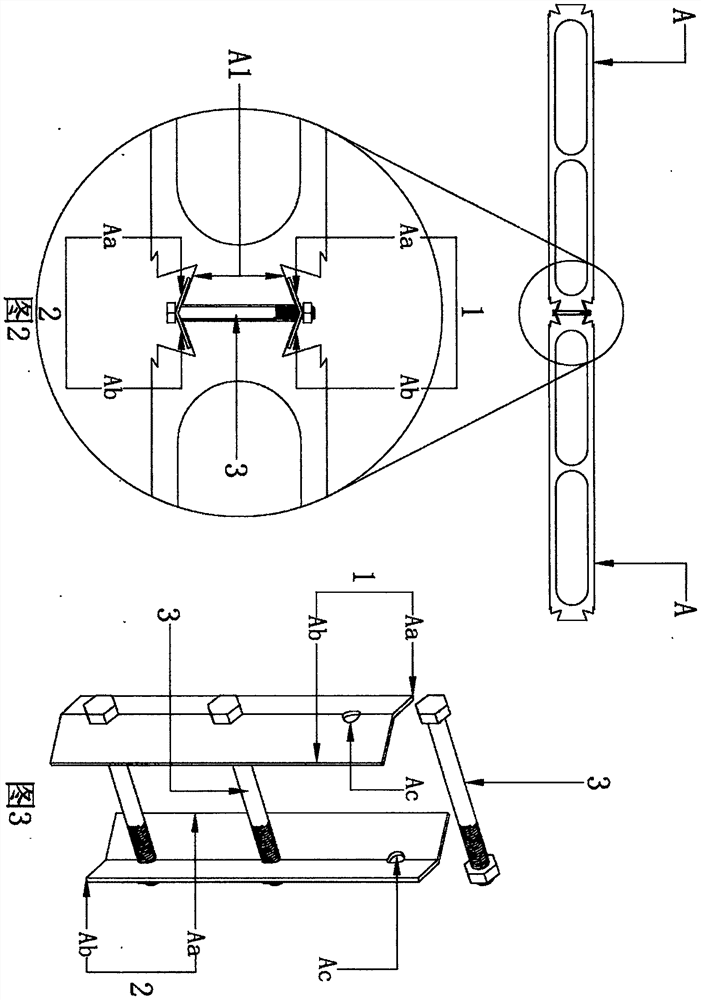

[0070] Such as figure 2 image 3 As shown, the locking clip includes a splint assembly I 1 , a splint assembly II 2 and a bolt assembly 3 . The splint assembly I 1 and the splint assembly II 2 are connected by a bolt assembly 3 . Both the splint assembly I 1 and the splint assembly II 2 include a left wing plate Aa and a right wing plate Ab fixedly connected together. The shapes of the side A1 match, and the left wing plate Aa and the right wing plate Ab form a V shape with an angle less than 180 degrees and greater than 90 degrees after being connected. The splint assembly I 1 and the splint assembly II 2 are clamped on the trapezoidal edge A1 of the zipper convex groove of the zipper type wall part A through its left wing plate Aa and right wing plate Ab to complete the lock between two lock type wall parts A. connect.

specific Embodiment 2

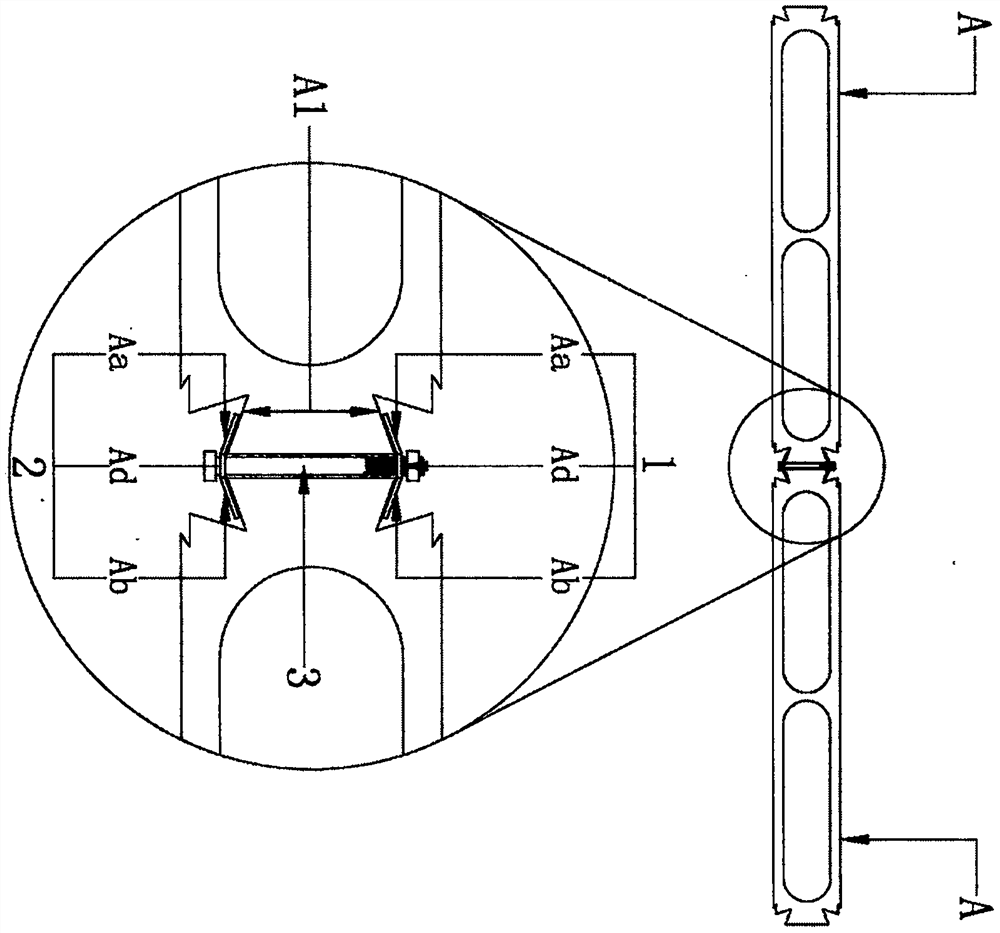

[0072] A locking clip for a zipper type wall part based on the first embodiment above. Such as Figure 4 Figure 5 As shown, the splint assembly I 1 and the splint assembly II 2 also include a straight connecting plate Ad; the left wing Aa and the right wing Ab are fixedly connected to both ends of the straight connecting plate Ad.

specific Embodiment 3

[0074] Such as Image 6 Figure 7 As shown, the locking clip includes a splint assembly I 1 , a splint assembly II 2 and a bolt assembly 3 , and the splint assembly I 1 and splint assembly II 2 are connected through the bolt assembly 3 . Both the splint assembly I 1 and the splint assembly II 2 include a left wing plate Aa and a right wing plate Ab fixedly connected together, the left wing plate Aa and the right wing plate Ab are straight shapes with an angle of 180 degrees after connection, and the left wing plate A protruding tenon strip Ae is formed on the lateral ends of the plate surface of the plate Aa and the right wing plate Ab. The splint assembly I 1 and the splint assembly II 2 are clipped on the trapezoidal edge A1 of the zipper convex groove of the zipper type wall part A through the two ends of the left wing plate Aa and the right wing plate Ab. Block lock type connection between wall parts A.

[0075] specific figure 2 Figure 4 The connection setting angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com