Assembly type wall surface mounting system and mounting method

An installation system, prefabricated technology, applied in covering/lining, building, building construction, etc., can solve problems such as non-adjustable distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

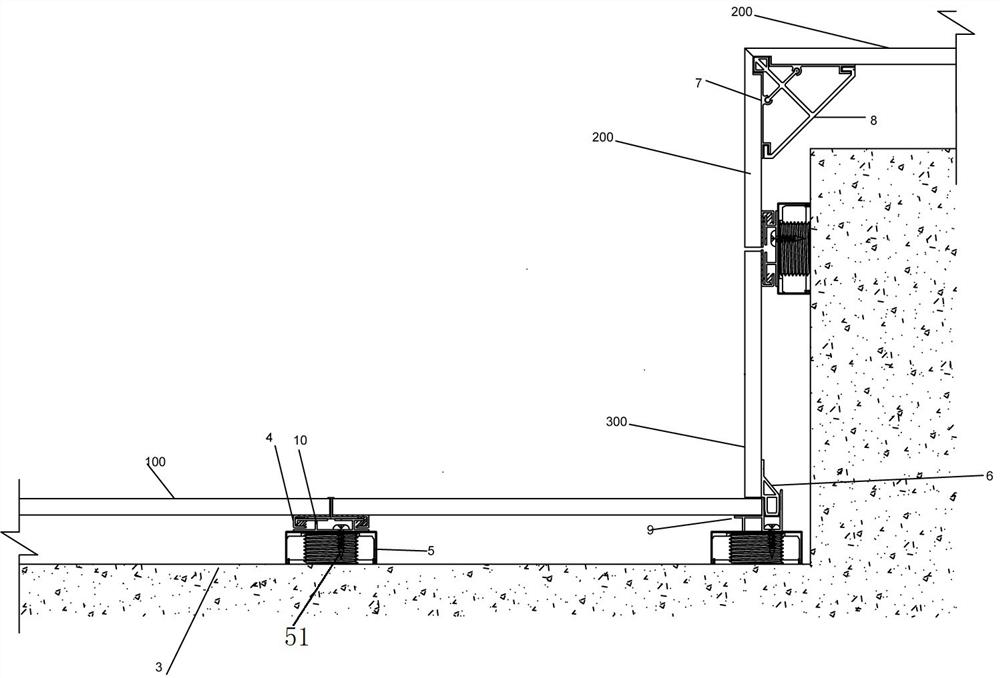

[0088] Such as figure 1 As shown, a prefabricated wall installation system is used to splice and install adjacent wall panels 100 on a flat wall 3 through a wall installation structure; The corner wall panels 300 are spliced together; at the male corners of the wall, the male corner wall panels 200, which are structural parts installed at the male corners of the wall, are assembled together, and finally the entire wall panels on the wall 3 are assembled.

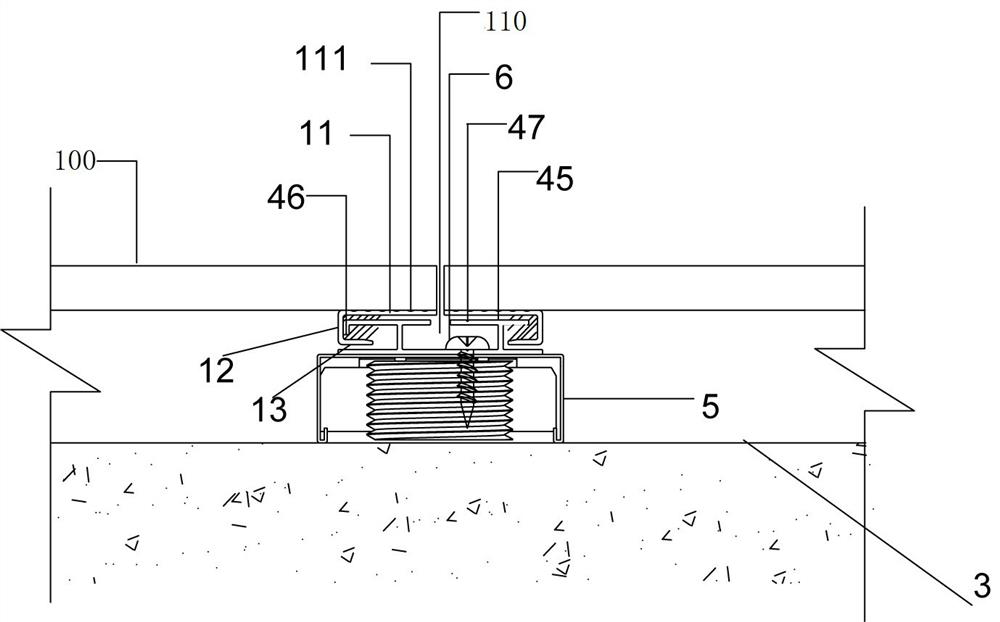

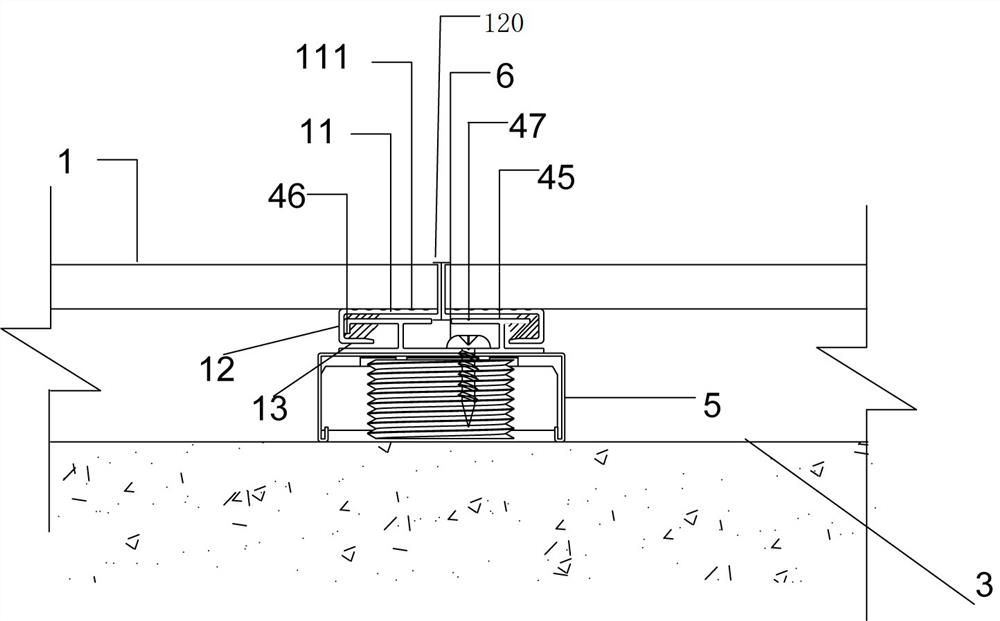

[0089] Specifically, such as figure 2 As shown, the wall installation structure is used to fix the wall panel 100 on the wall 3. The wall installation structure includes: a wall panel connector 10 having a first positioning installation groove 14, and a wall panel attached to the wall panel. 100 and connected to the fixed first bonding surface 11 of the wallboard 100; the wall surface connection fixture 4 has a positioning plate 40 that can be inserted into the first positioning installation groove 14 and can move in the...

specific Embodiment

[0115] A specific embodiment of this program includes the following steps:

[0116] S2-1: Connect the male corner fixing part 7 to the male corner wallboard 200, set adhesive glue on the male corner wallboard 200 or the fourth fitting surface 73, and attach the fourth fitting surface 73 to the male corner wall Plate 200 and place the positioning plate 74 at the end of the fourth fitting surface 73 on the side wall of the chamfered milling groove, repeat the above steps, and connect the two male corner wall panels 200 at the male corner to the upper male corner fixing member 7;

[0117] S2-2: Connect the male corner fixing part 7 to the male corner buckle connector 8, fill the second limiting groove 72 with adhesive glue, insert the first limiting block 811 and the second line 823 into the first The limit groove 71 and the second limit groove 72 are spliced together with the two male corner wall panels 200 so that the two chamfered milling grooves are spliced into a connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com