Synchronous reciprocating mechanism for ball screw and guide rail experiment and testing device

A technology of reciprocating mechanism and ball screw, which is applied in the field of synchronous reciprocating mechanism and testing device, which can solve the problems of high cost, insufficient accuracy of the control group, and the inability of the motor movement to be exactly the same.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

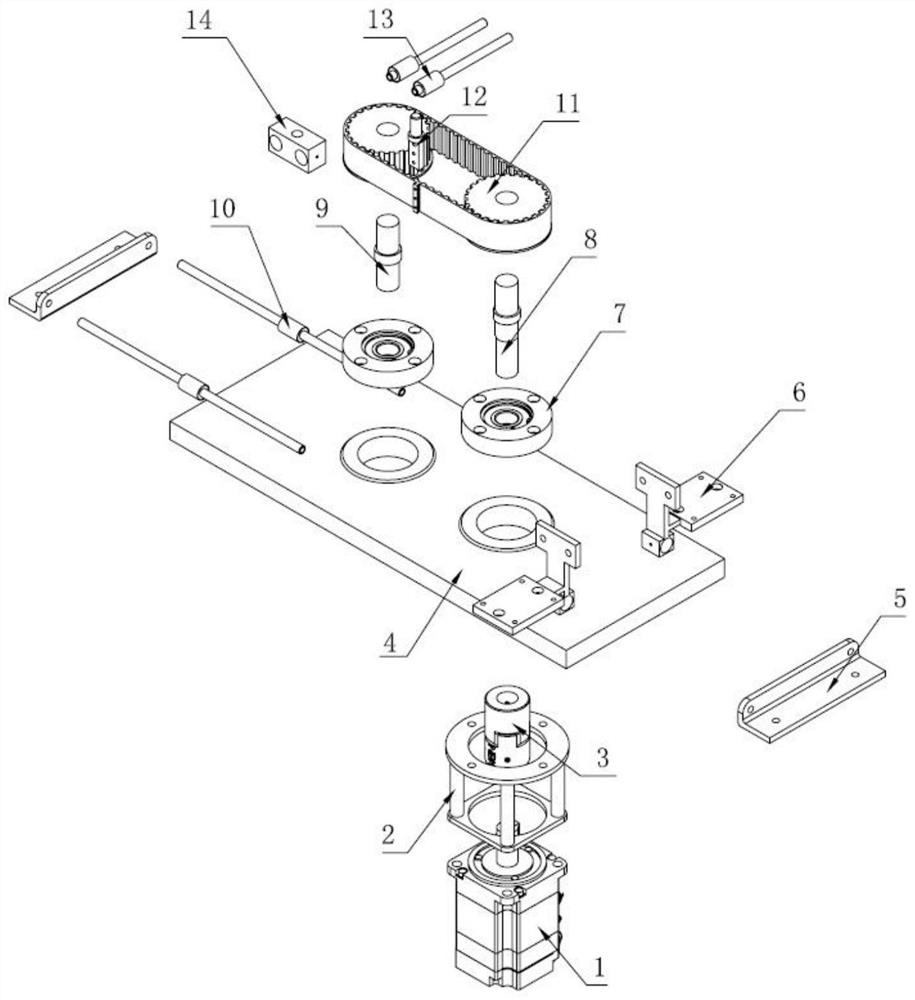

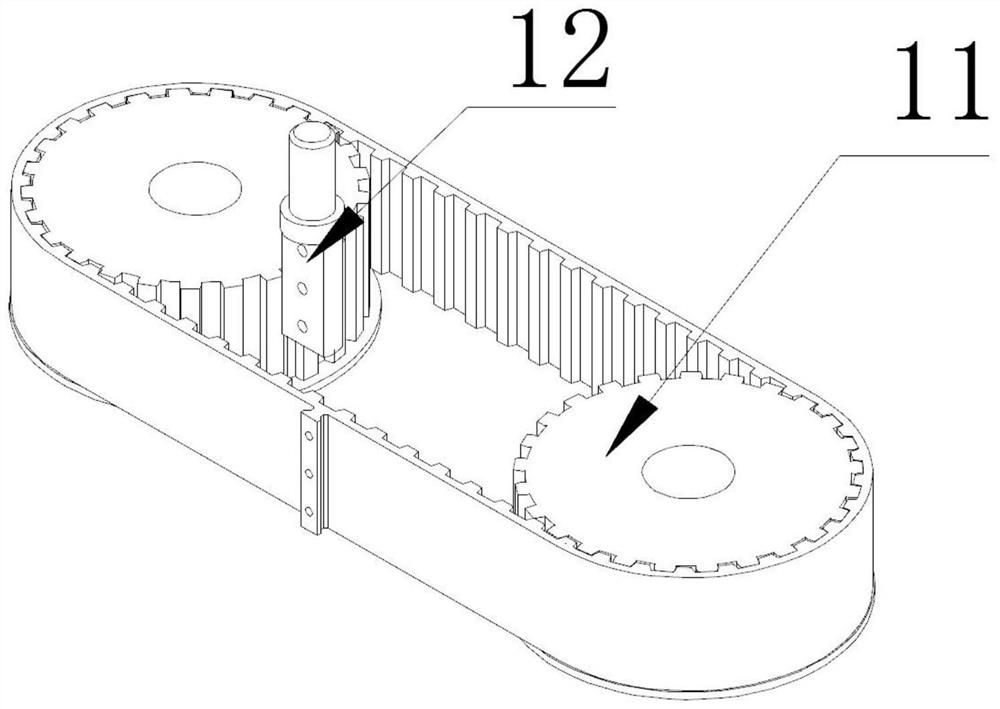

[0027] As an implementation, the lower guide mechanism includes a support 5 and a second guide rod 10; the two ends of the second guide rod 10 are respectively supported on the support 5, and the support 5 is fixed on the working position by screws. On the platform 4; the connecting member 6 can slide horizontally along the second guide rod 10 on the corresponding side; the second guide rod 10 is parallel to the center line connecting the driving wheel and the driven wheel of the synchronous belt transmission mechanism 11 .

[0028] Based on the above-mentioned synchronous reciprocating mechanism, the present invention also proposes a test device for ball screw and guide rail experiments. , connector 6, guide 12, test lead screw 19, test guide rail 17;

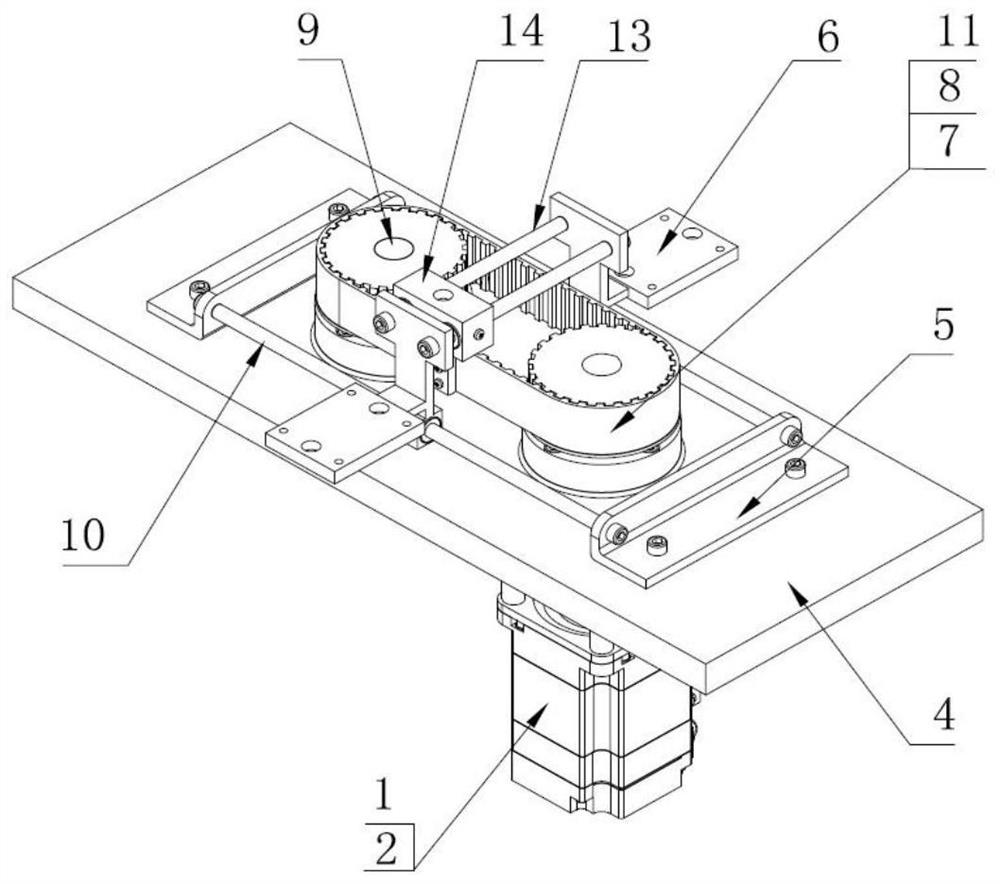

[0029] The drive motor 1 is arranged at the lower end of the workbench 4; the drive motor 1 is fastened and connected to the bottom of the workbench 4 through the motor connector 2, and the synchronous belt transmission mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com