Flue gas detection method based on FTIR technology

A technology for smoke detection and technology, which is used in measurement devices, color/spectral property measurement, suspension and porous material analysis, etc., and can solve problems such as interference, inaccurate detection results, and inevitable simultaneous removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

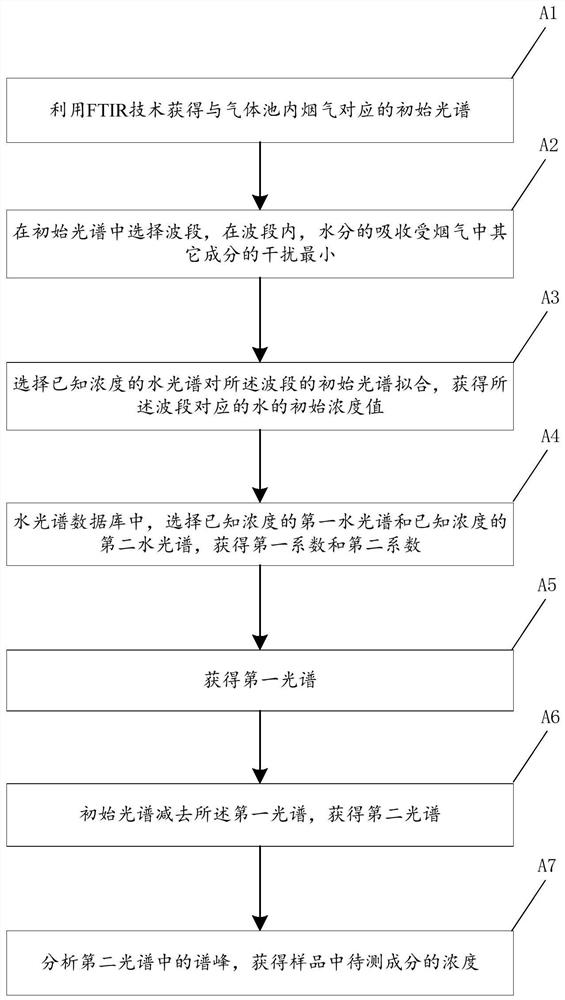

[0031] figure 1 The flow chart of the smoke detection method based on FTIR technology of the embodiment of the present invention is given, as figure 1 Shown, described smoke detection method based on FTIR technology comprises the following steps:

[0032] (A1) Using FTIR technology to obtain an initial spectrum corresponding to the flue gas in the gas pool, the flue gas contains moisture;

[0033] The flue gas is heated to 180 degrees in the pipeline from the flue to the gas pool to prevent the moisture in the flue gas from condensing and losing the components to be measured;

[0034] (A2) Select a band in the initial spectrum, within the band, the absorption of moisture is least interfered by other components in the flue gas, such as not interfered by other components;

[0035] (A3) Select the water spectrum of known concentration to fit the initial spectrum of the band, and obtain the initial concentration value C of the water corresponding to the band 0 ;

[0036] (A4) ...

Embodiment 2

[0047] An application example of the smoke detection method based on FTIR technology according to Embodiment 1 of the present invention.

[0048] In this application example, the smoke detection method based on FTIR technology in the embodiment of the present invention includes the following steps:

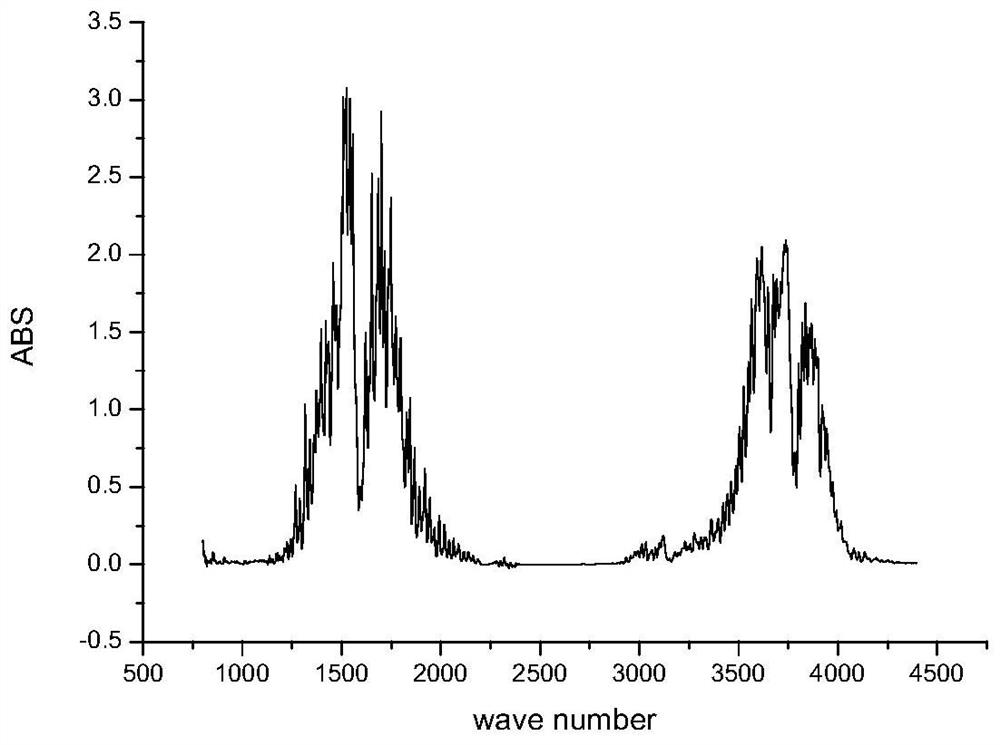

[0049] (A1) Use FTIR technology to obtain the initial spectrum corresponding to the flue gas in the gas pool, such as figure 2 As shown, the flue gas contains moisture;

[0050] The flue gas is heated to 180 degrees in the pipeline from the flue to the gas pool to prevent the moisture in the flue gas from condensing and losing the components to be measured;

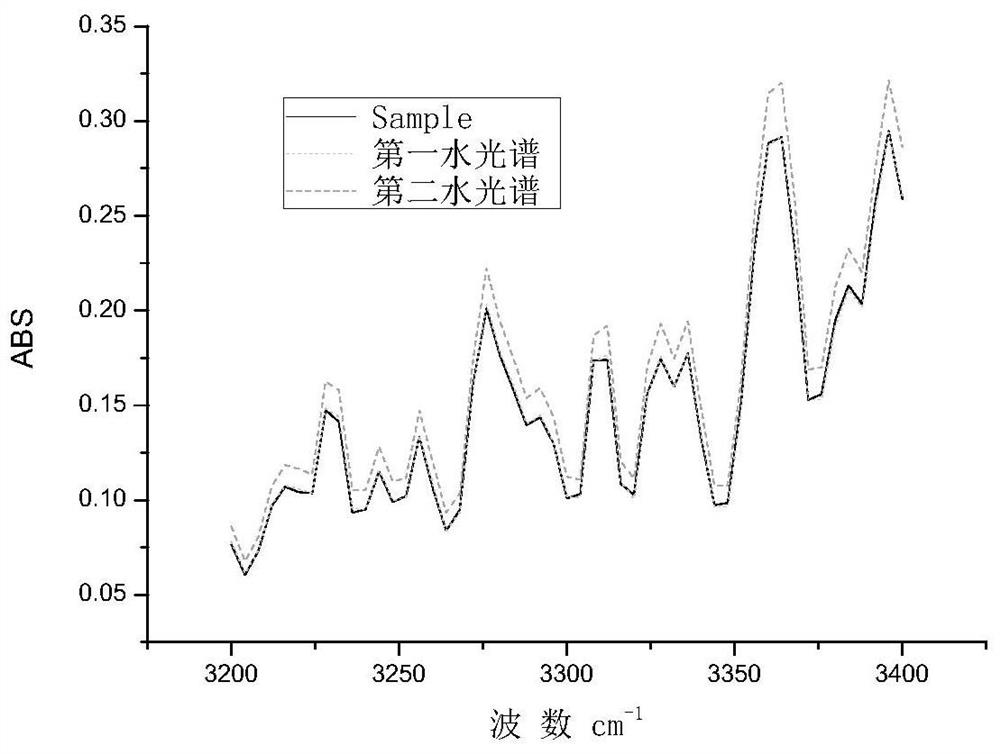

[0051](A2) Select a waveband in the initial spectrum, the waveband is 3200-3400 wavenumber, and in the waveband, the absorption of moisture is minimally interfered by other components in the flue gas, such as not interfered by other components;

[0052] (A3) Select the water spectrum of known concentration to fit the initi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap