Positioning feeder for solid samples

A feeding device and sample technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of unsuitable working space range instruments, sampling position deviation, inaccurate measurement, etc., to achieve easy disassembly, Easy to troubleshoot and easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

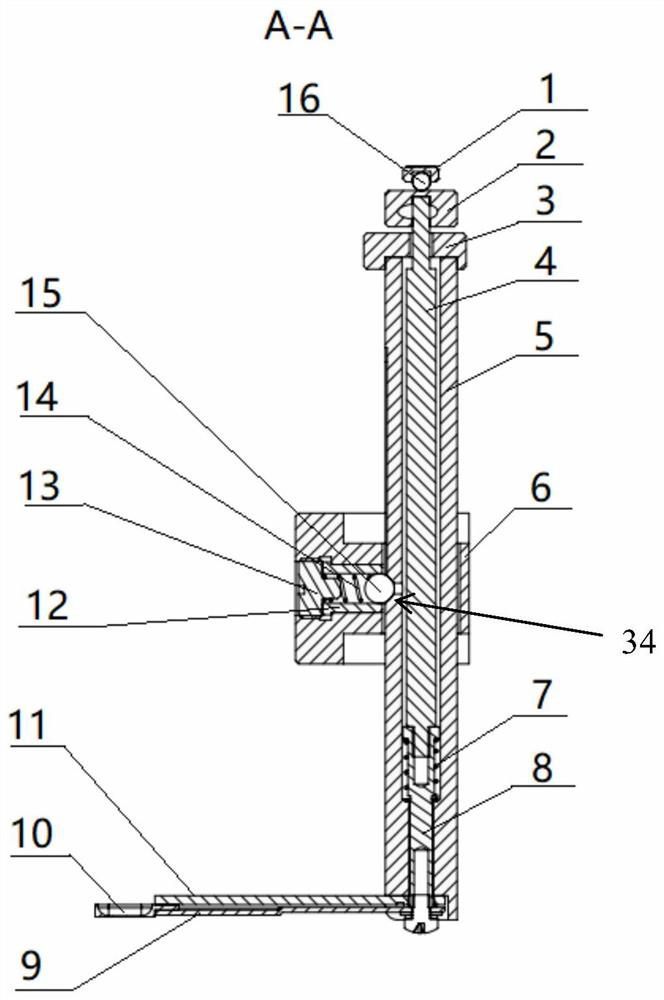

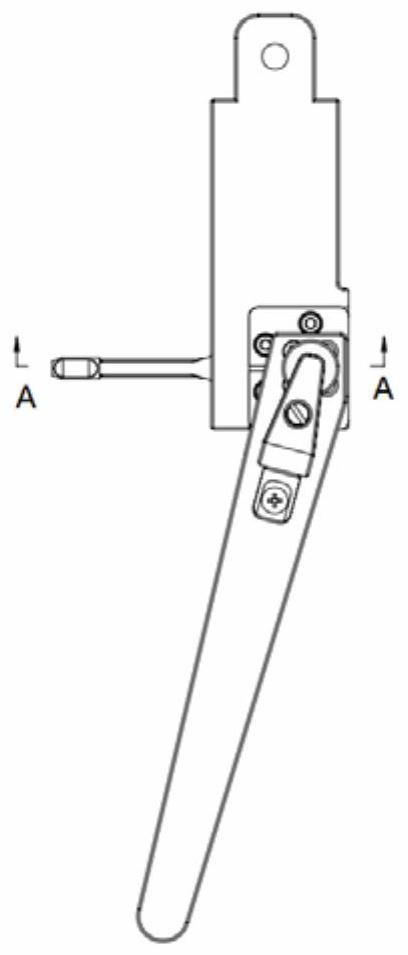

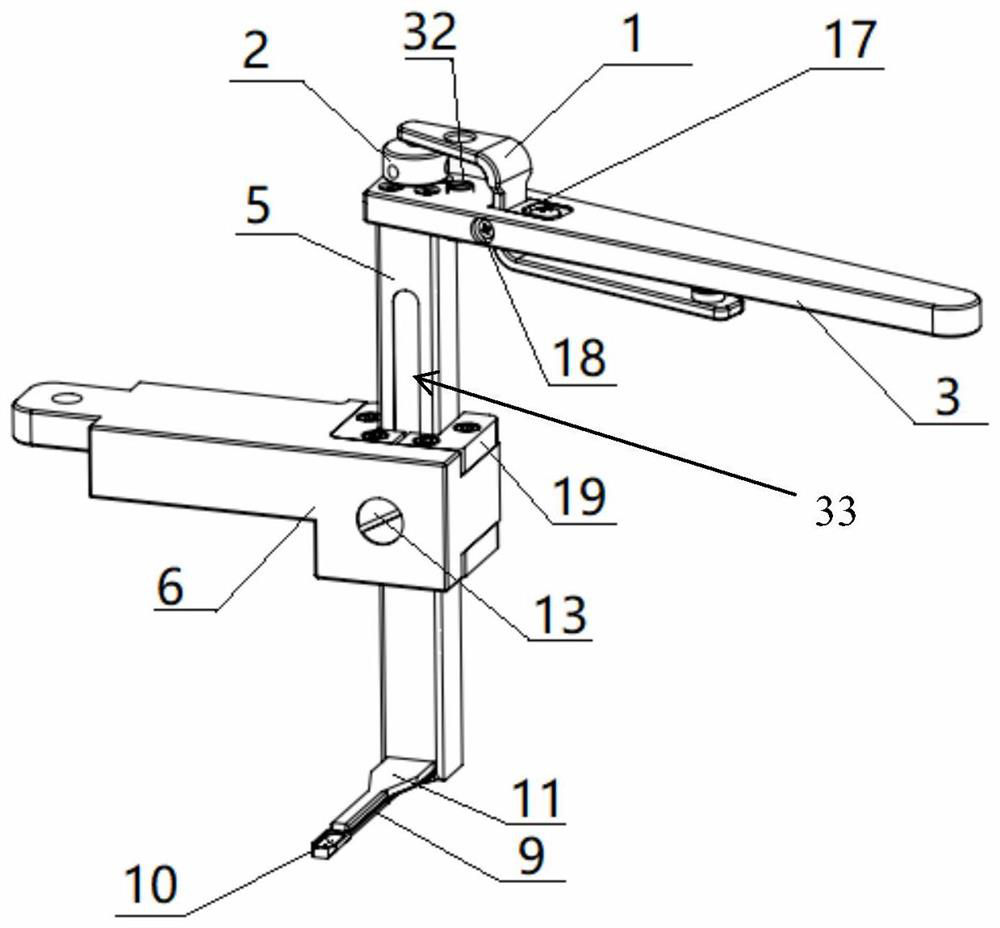

[0030] The invention provides a positioning and feeding device for a solid sample, which is composed of a feeding arm and a clamping device.

[0031] like figure 1 , figure 2 and image 3 As shown, the feeding arm consists of a release lever 1, a release button 2, a handle 3, a transmission shaft 4, a square shaft body 5, a sampling cantilever 6, a return spring 7, a return spring shaft 8, and a v-shaped lower positioning pliers 9 , graphite sample spoon 10, upper positioning pliers 11, positioning sleeve 12, ball pressure nail 13, positioning spring 14, ball 15, steel ball 16, adjustment block 17, shaft nail 18, limit block 19 and limit nail 32.

[0032] like figure 1 , one end of the transmission shaft 4 is screwed into the return spring shaft 8, the return spring shaft 8 is sleeved into the return spring 7, the transmission shaft 4, the return spring shaft 8 and the return spring 7 are integrally inserted into the square shaft body 5, and the return spring 7 elastically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com