Sectional panel tank

A technology of assembling boards and storage boxes, applied in the directions of packaging, packaging food, transportation and packaging, etc., can solve the problems of poor chemical resistance, unsuitable for water-sealed storage, etc., to overcome leakage and corrosion, safe and reliable storage or transportation, The effect of significant practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

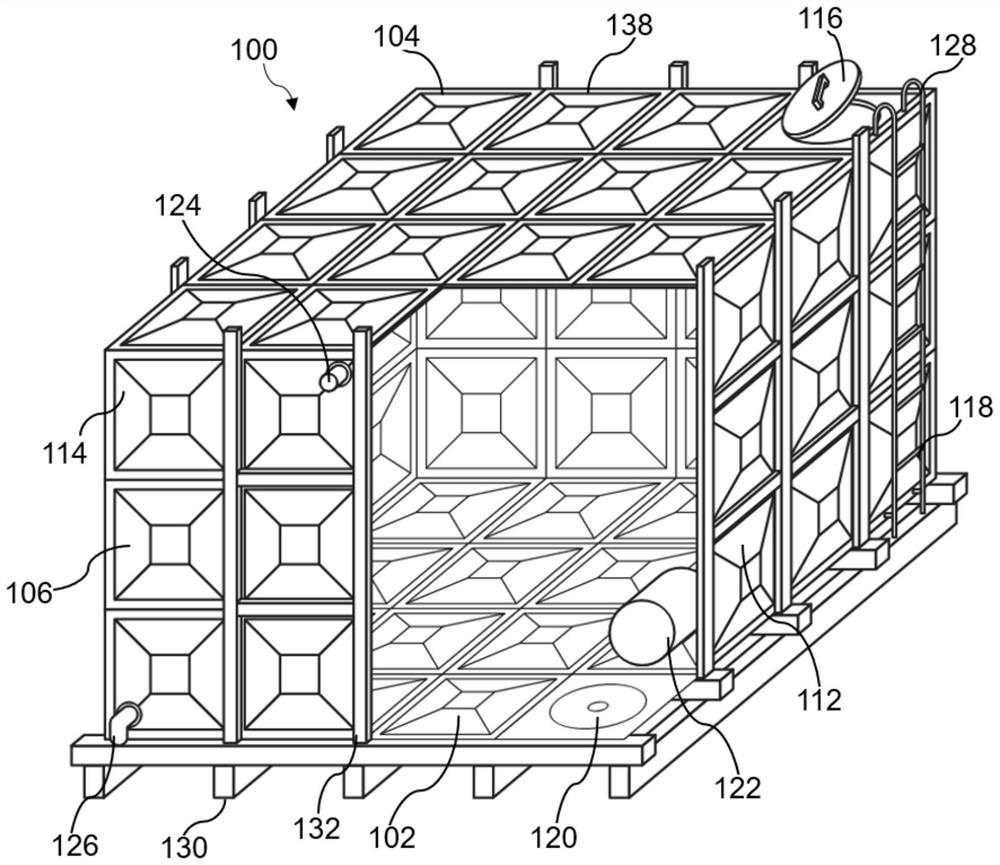

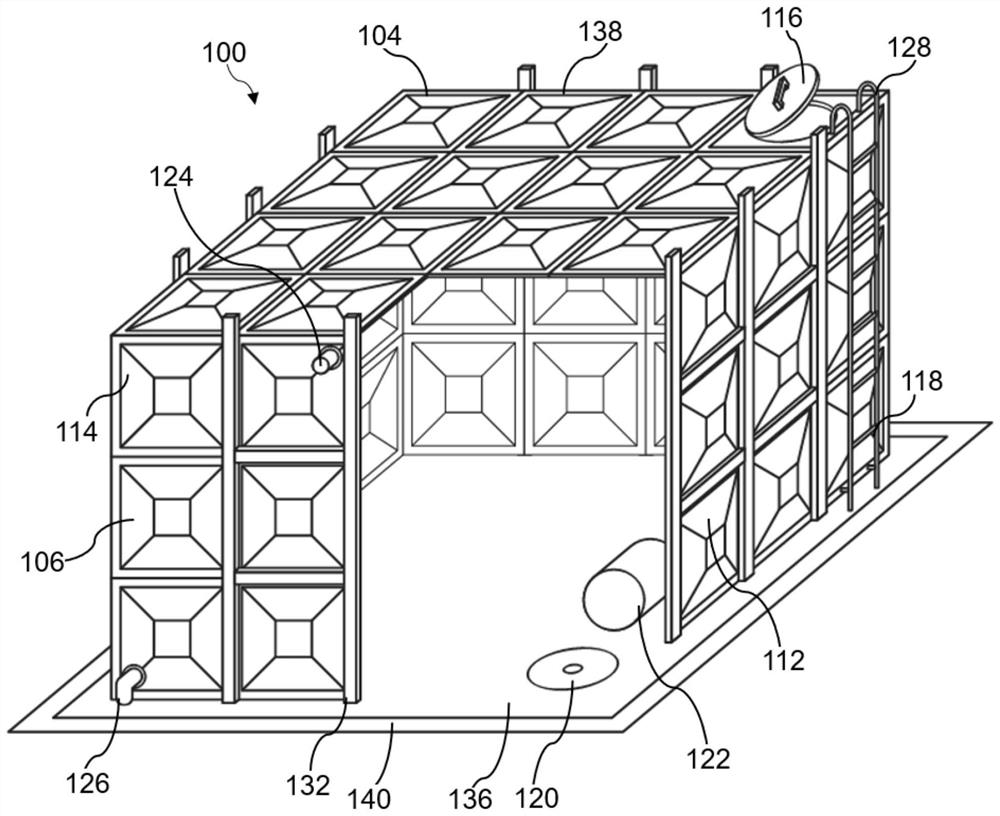

[0102] figure 1 is a partially exploded view of the first panel tank 100 having the outer base 130 . Depend on figure 1 As shown, it can be seen that the first panel tank 100 has a cubic dimension with a bottom wall 102, a top cover 104 and four side walls including a front wall 106, a rear wall 108 (not shown), a left wall 110 (not shown). out) and the right wall 112. Thus, the first panel tank 100 has twelve edges 138 . The bottom wall 102 , the top cover 104 and the side walls 106 , 108 , 110 , 112 are assembled by a plurality of unit boards 114 . The first paneled tank 100 also includes an inspection hole or manhole 116 at the corner of the top cover 104 , a ladder 118 secured to the right wall 112 , a drain hole 120 connected to a drain 122 , an inlet 124 and an outlet 126 , which are located above and below the front wall 106, respectively. In particular, the top end 128 of the ladder 118 is located near the access hole 116 . In addition, an external base 130 is pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com