Perillaseed sauce preparation method

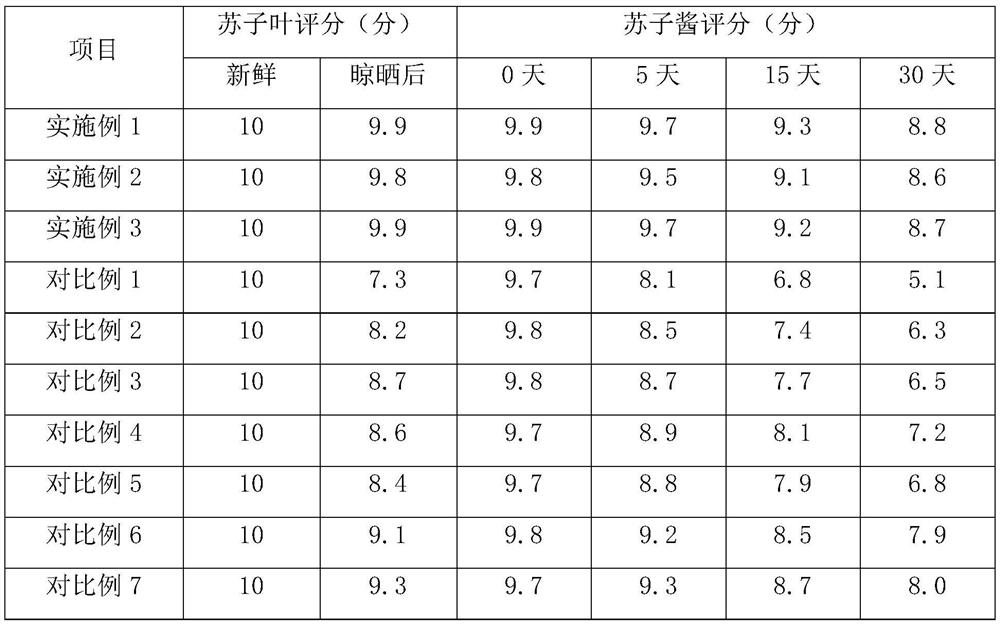

A technology of suzi paste and suzi leaves, which is applied in the field of preparation of suzi paste, can solve the problems of weakening the fragrance of suzi leaves and suzi, and achieves the effects of good ductility, good oxygen barrier performance and good oxygen barrier effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

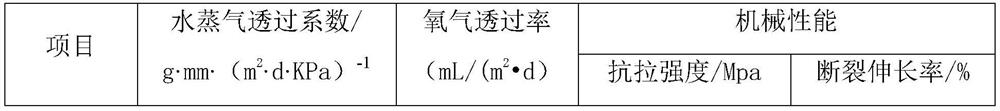

preparation example 1

[0036] Preparation example 1: Soybean protein composite film liquid is prepared by the following method:

[0037] S11. Weigh 5kg soybean protein isolate, 2kg carrageenan, 6kg glycerin, and 100kg water, heat up to 80°C after mixing, then perform magnetic stirring for 30min, adjust pH=7.5 after stirring, and then vacuum degas under the condition of 0.09Mpa for 4min, After cooling to 40°C, the soybean protein composite film liquid was prepared.

preparation example 2

[0038] Preparation example 2: Soybean protein composite film liquid is prepared by the following method:

[0039] S11. Weigh 3kg of soybean protein isolate, 1kg of carrageenan, 4kg of glycerin, and 90kg of water, heat up to 75°C after mixing, then perform magnetic stirring for 25min, adjust pH=6 after stirring, and then vacuum degas under the condition of 0.08Mpa for 2min, After cooling to 40°C, the soybean protein composite film liquid was prepared.

preparation example 3

[0040]Preparation example 3: Soybean protein composite film liquid is prepared by the following method:

[0041] S11. Weigh 6kg of soybean protein isolate, 3kg of carrageenan, 8kg of glycerin, and 110kg of water, heat up to 85°C after mixing, then perform magnetic stirring for 35min, adjust pH=8 after stirring, and then vacuum degas under the condition of 0.1Mpa for 5min, After cooling to 40°C, the soybean protein composite film liquid was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com