An automatic cleaning device for the rotating shaft of the condenser

An automatic cleaning and rotating shaft technology, applied in cleaning methods and utensils, chemical instruments and methods, and cleaning methods using liquids, etc. problems, to achieve the effect of convenient installation, compression and pull-out, high cleaning efficiency and good cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

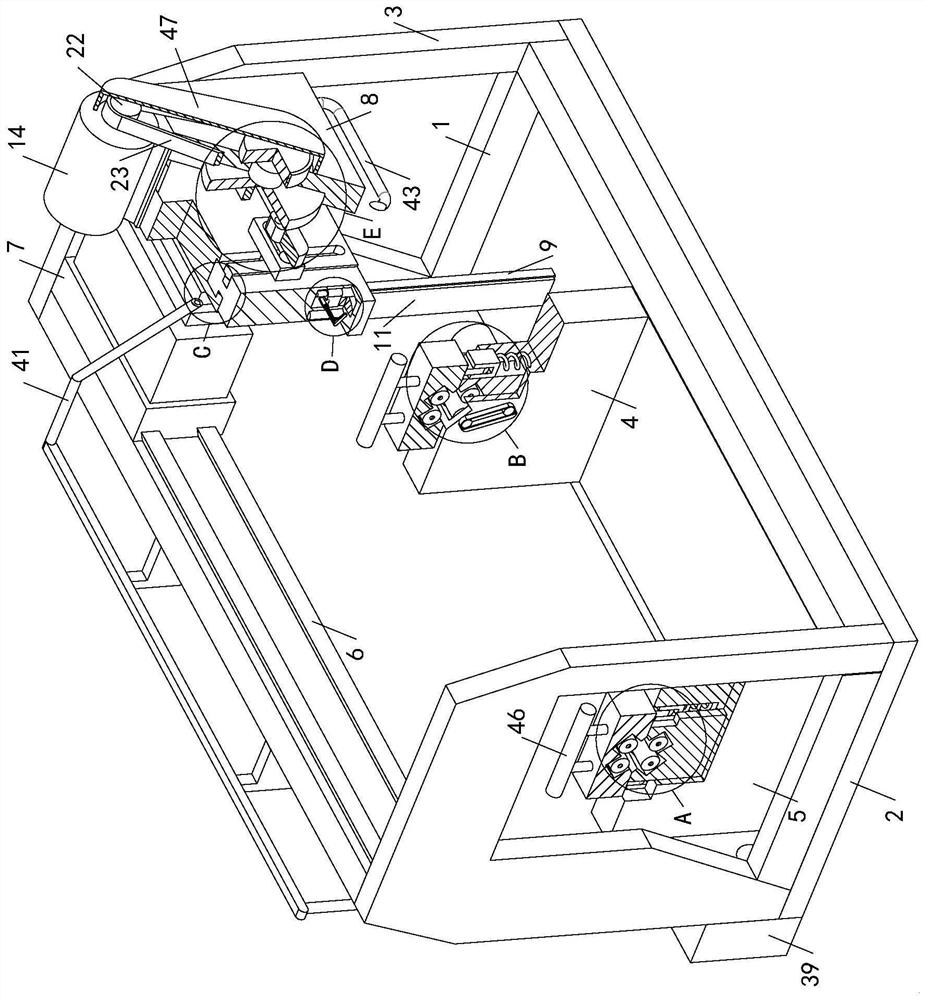

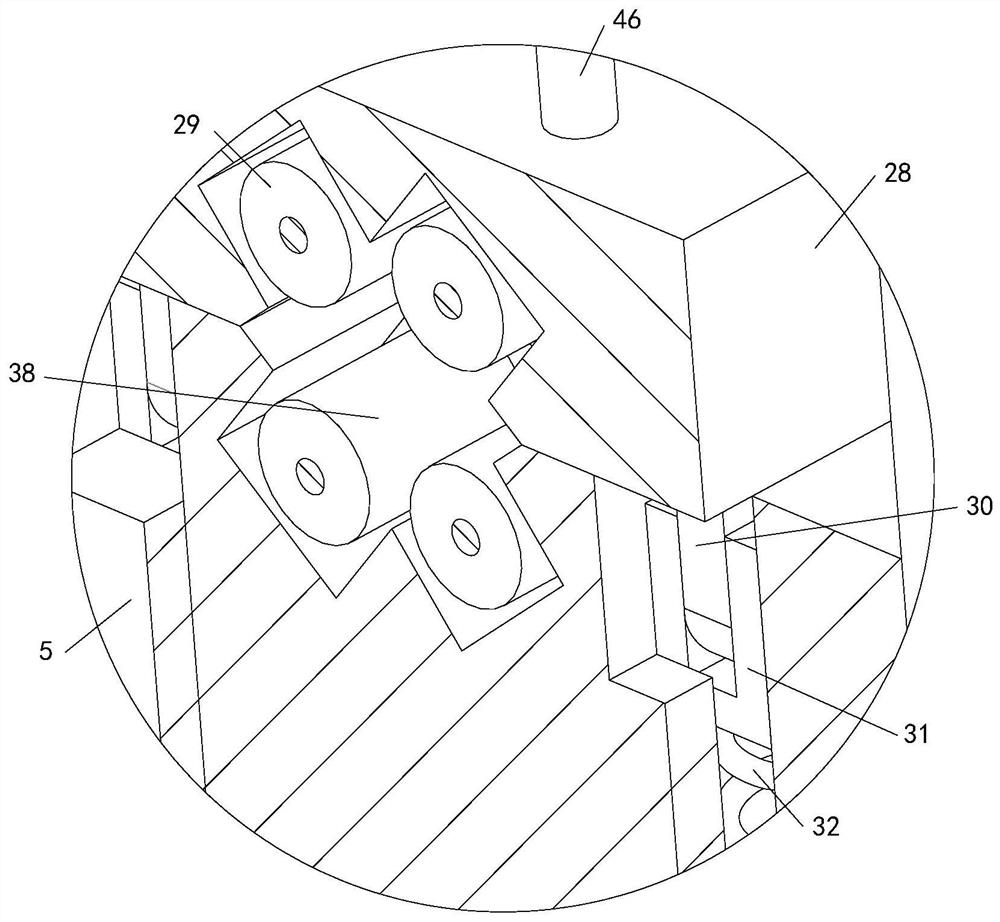

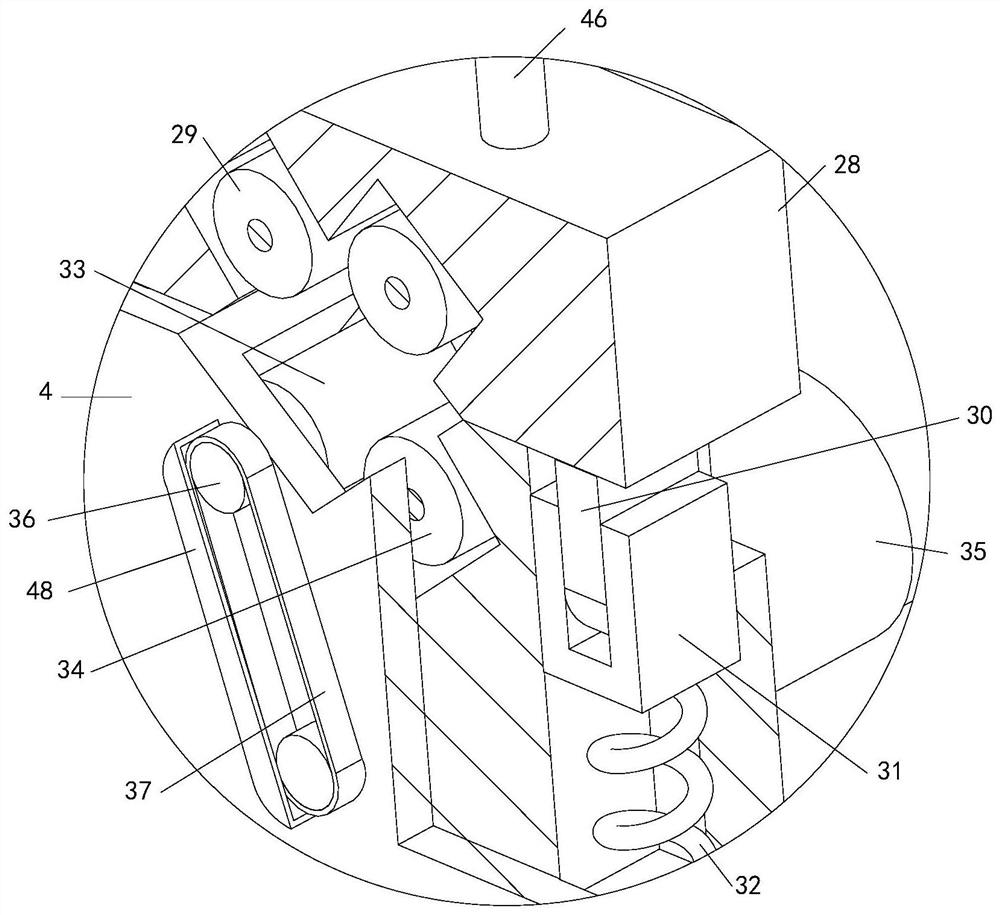

[0034] see Figure 1-8 , an automatic cleaning device for the rotating shaft of a condenser, comprising a water collecting pan 1 and a bottom plate 2, the water collecting pan 1 is fixedly connected to the bottom plate 2, and the bottom plate 2 is fixedly connected with a mounting frame 3, a power frame 4 and a support frame 5. The telescopic arm 7 is slidably connected to the installation frame 3 through the dovetail rail 6, and the front end of the telescopic arm 7 is fixedly connected to the mobile frame 8. The cleaning mechanism, the reciprocating mechanism and the angle adjustment mechanism are installed on the mobile frame 8. The power frame 4 and the support The frame 5 is equipped with a runner mechanism and a supporting wheel mechanism respectively, and the runner mechanism includes a power wheel 33, an auxiliary wheel 34 and a servo motor 35, and the power wheel 33 and the auxiliary wheel 34 are all rotatably connected with the power frame 4, and the servo motor 35 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com