A two-color injection mold

A two-color injection molding and mold technology, applied in the field of mold injection molding, can solve the problems of large injection molding machines and high production costs, and achieve the effects of flexible use, convenient operation and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

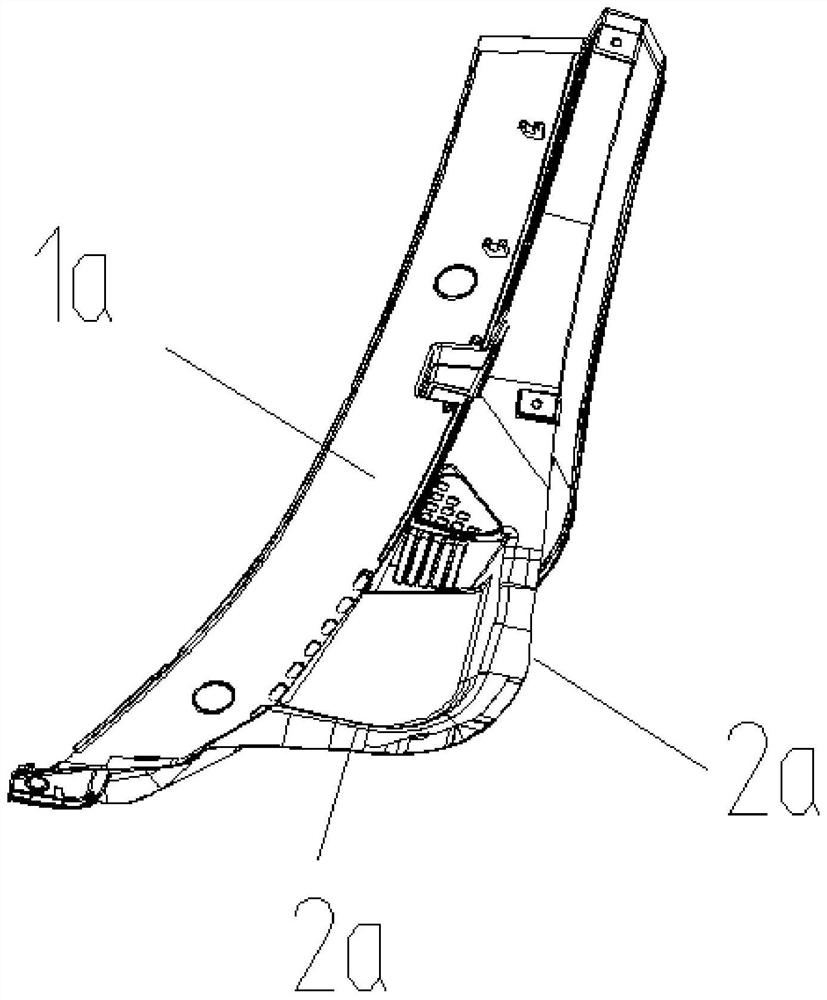

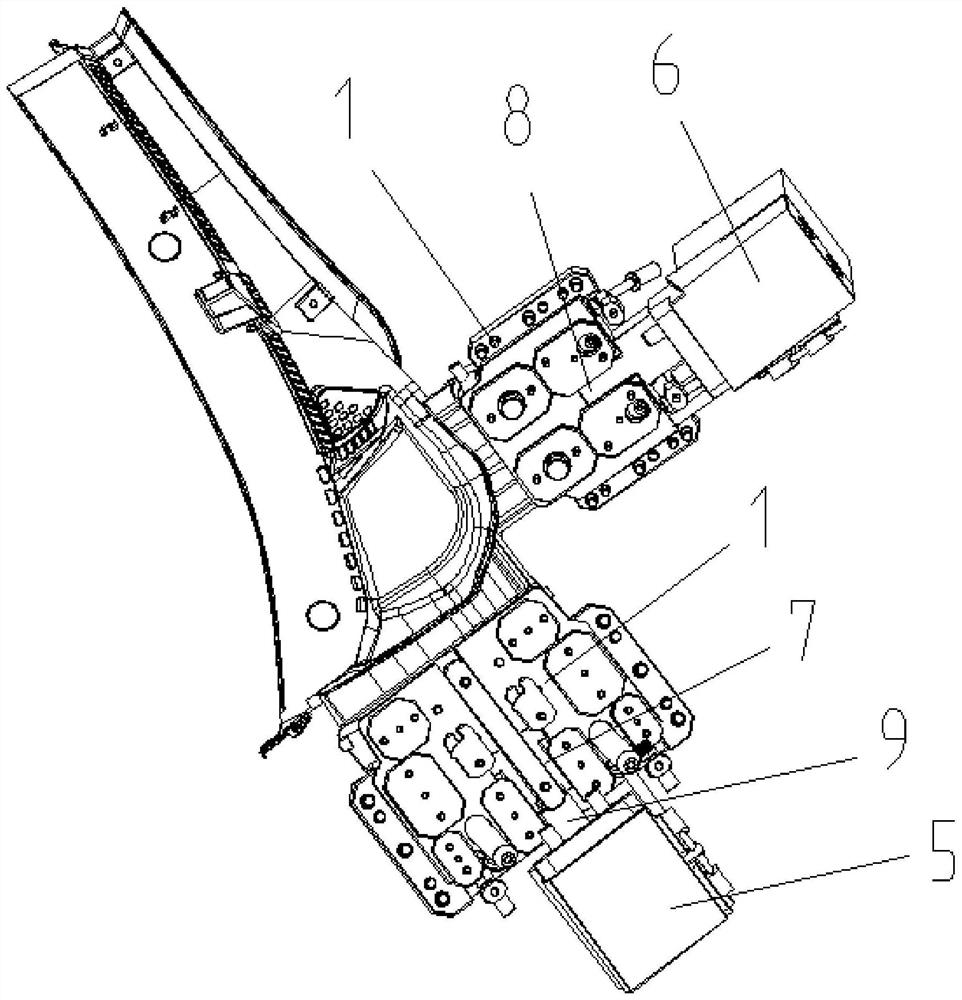

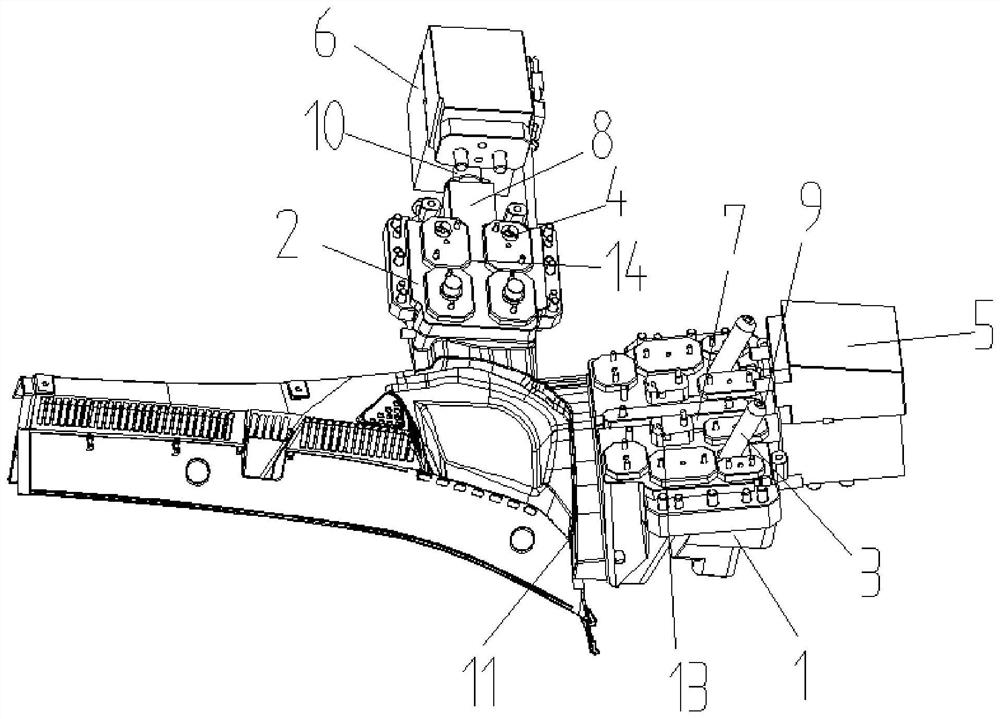

[0020] A two-color injection mold, comprising a first sliding block 1 disposed on the front side of the product, a second sliding block 2 on the right side of the product, a first inclined guide post 3 for driving the first sliding block 1, and a first sliding block 3 for driving the first sliding block 1. The second inclined guide column 4 of the two sliding blocks 2 can be installed using the prior art, and further includes a first oil cylinder 5 disposed outside the first sliding block 1 , and a first oil cylinder 5 disposed outside the second sliding block 2 . In the second oil cylinder 6, a first guide seat 7 and a second guide seat 8 are provided on the side of the first slider 1 close to the first oil cylinder 5 and the side of the second slider 2 near the second oil cylinder 6, respectively. The free end 9 of the first oil cylinder 5 and the free end 10 of the second oil cylinder 6 are slidably connected with the first guide seat 7 and the second guide seat 8 respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com