Railway steel rail center detection vehicle

A technology for detecting vehicles and rails, applied in the field of track detection, can solve the problems of high cost, low measurement accuracy, low work efficiency, etc., and achieve the effects of low cost, high measurement accuracy, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

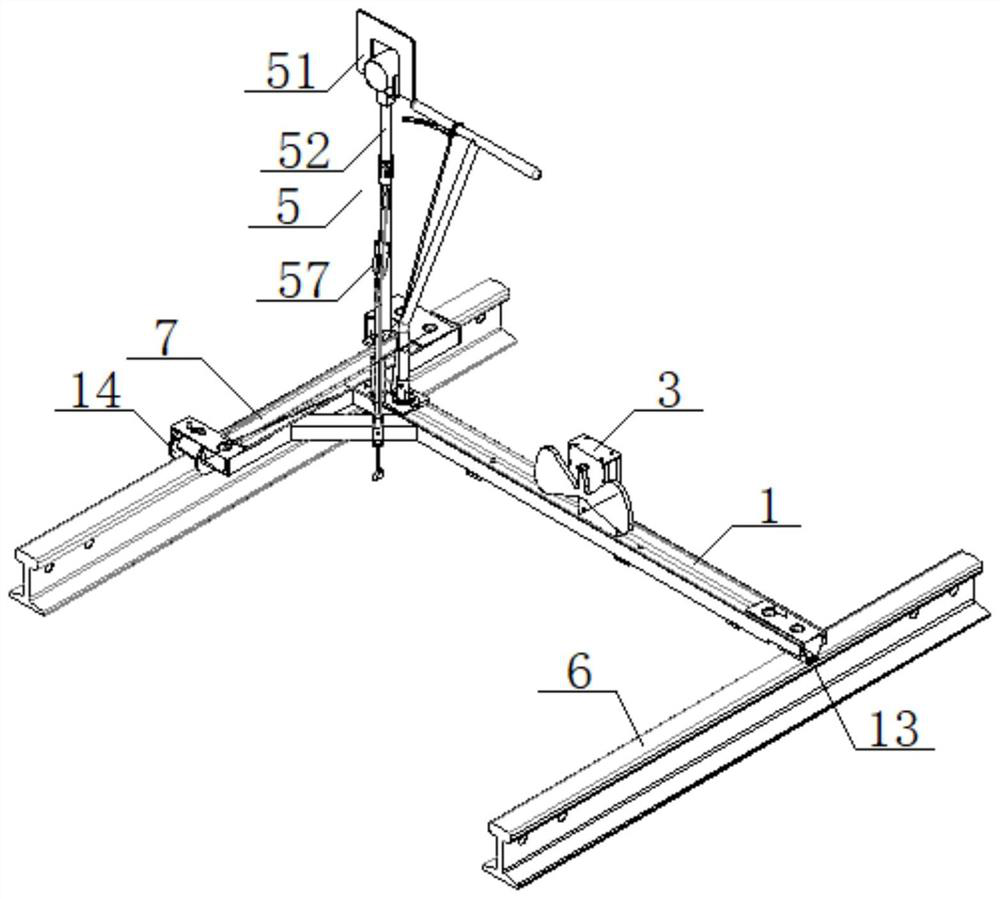

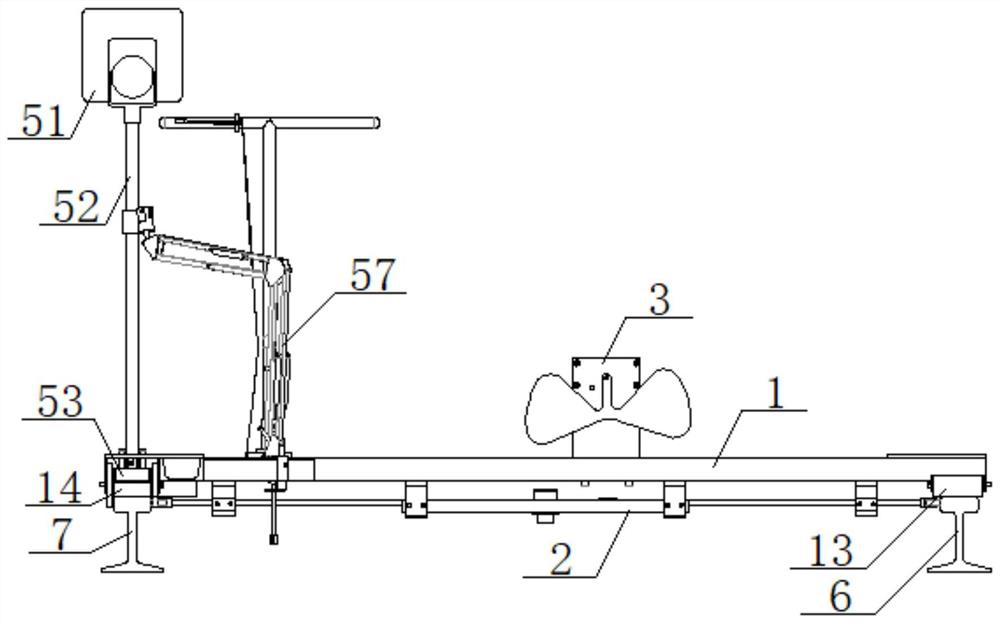

[0067] see Figure 1 to Figure 24 , a railway rail center detection car, comprising a trolley 1 and a No. 1 prism measuring device 5; the trolley 1 includes a connected frame 11 and a push rod 12, and the bottom of one end of the frame 11 is provided with a nylon Wheel 13, nylon wheel 13 is arranged on the left rail 6, and the bottom of vehicle frame 11 other ends is provided with steel channel wheel 14, and steel channel wheel 14 is stuck on the right rail 7; Described No. 1 prism measuring device 5 comprises No. 1 prism 51. The No. 1 prism rod 52 and the joint bearing seat 53, the middle part of the joint bearing seat 53 is provided with a mounting hole 531, and the joint bearing 54 is arranged in the installation hole 531, and the two sides of the joint bearing seat 53 are provided with limited positions. Bolt 55 is arranged in the hole 532, the limit hole 532, and the bolt 55 withstands the joint bearing 54, the joint bearing seat 53 is located directly above the right rai...

Embodiment 2

[0069] Basic content is the same as embodiment 1, the difference is:

[0070] see Figure 1 to Figure 24 , the vehicle frame 11 is a T-shaped structure, the vehicle frame 11 includes a beam 111 and a longitudinal beam 112, the bottom of one end of the beam 111 is provided with a nylon wheel 13, and the other end of the beam 111 is vertically connected with the longitudinal beam 112, so The longitudinal beam 112 is located directly above the right rail 7, and the bottoms of the two ends of the longitudinal beam 112 are provided with steel sheaves 14, and the push rod 12 is connected with the cross beam 111; the walking trolley 1 also includes a braking device 15, so The brake device 15 includes a brake handle 150, a brake lever 151 and a brake shoe 152. One end of the brake lever 151 is connected to a brake pull pin 153, and the other end of the brake lever 151 is connected to the brake handle 150 through a brake wire 154. Connected, the brake handle 150 is connected with the ...

Embodiment 3

[0072] Basic content is the same as embodiment 1, the difference is:

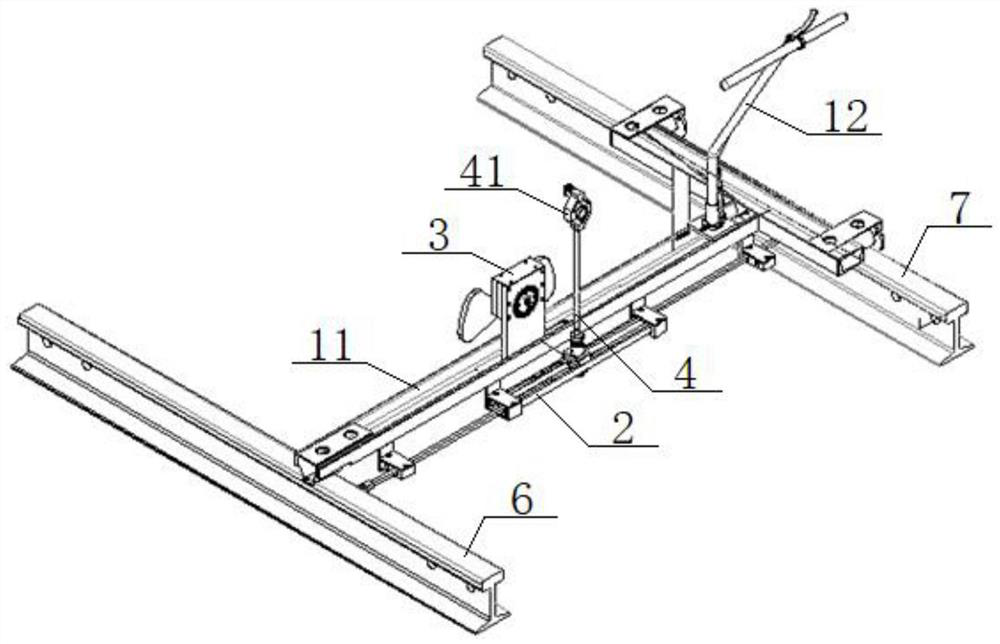

[0073] see Figure 1 to Figure 24 , the frame 11 is provided with a gauge measuring ruler 2, and the gauge measuring ruler 2 includes a base plate 21, a No. 1 rack 22 and a No. 2 rack 23, and an intermediate gear 24 is arranged at the center of the base plate 21 , the positions on both sides of the intermediate gear 24 on the bottom plate 21 are respectively provided with a No. 1 installation groove 211 and a No. 2 installation groove 212. 24 are engaged with each other, and one end of the No. 1 rack 22 is provided with a mounting column 221, and the No. 1 spring 25 is set on the mounting post 221. The No. 1 spring 25 is fixed in the No. 1 mounting groove 211 through the spring pressing block 26, and the No. 1 rack 22 The other end of the electric insulating bearing 222 is connected with an electrically insulating bearing 27, the scale 223 is set on the No. 1 rack 22, the No. 2 rack 23 is set in the No. 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com