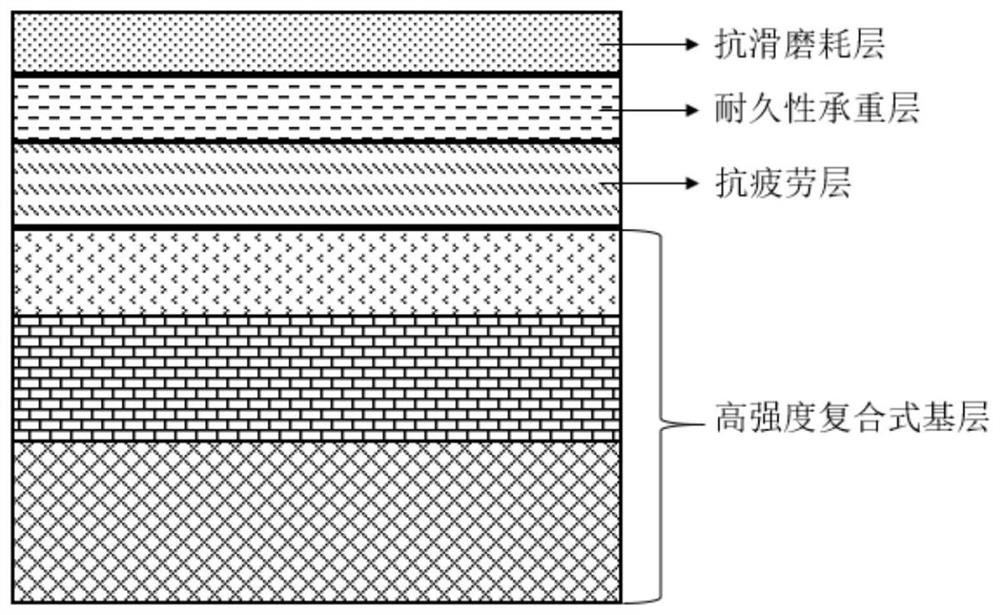

A combined ultra-thin long-life pavement structure and construction method thereof

A pavement structure and combined technology, applied in the direction of roads, roads, and on-site coagulation pavements, can solve the problems of inability to reflect the performance advantages of structural layers, poor temperature stability of asphalt pavements, and insufficient coordination and cooperation. Saving road construction materials, good durability and small thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 Engineering application of combined ultra-thin and long-life pavement structure

[0037] On October 27, 2020, the combined ultra-thin and long-life pavement structure was applied to the K3+381 level crossing, K3+460~K3+960 of Huanghai 4th Road (Lushan Road to Lanji Road), Linyi City, Shandong Province. The specific pavement structure It is cement stabilized gravel + macroporous polyurethane gravel + rubber powder polyurethane mixture layer + polyurethane mixture layer + anti-slip wear layer, and the length of the road section is 600m.

[0038] 1. Material composition of each structural layer

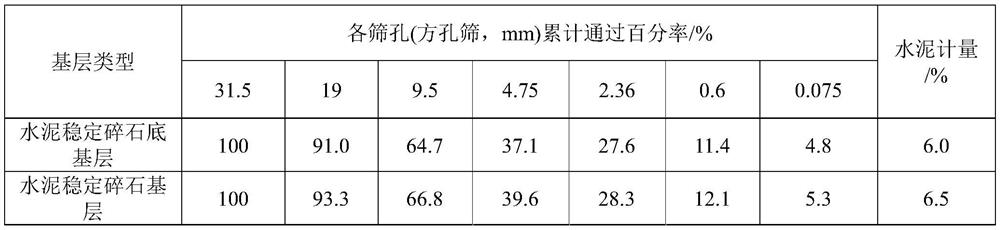

[0039] The cement-stabilized crushed stone is composed of aggregates of 0-5mm, 5-10mm, and 10-30mm in a ratio of 35:45:20. The synthetic gradation is shown in Table 1.

[0040] Table 1 Synthetic gradation of cement stabilized crushed stone

[0041]

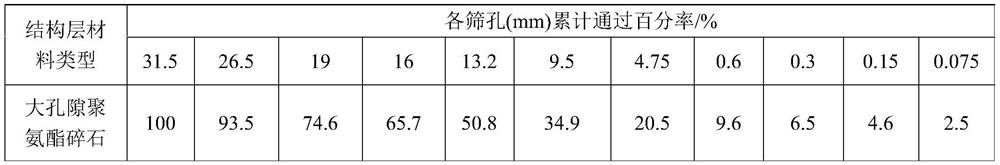

[0042] The macroporous polyurethane crushed stone base is prepared by mixing 0~3mm, 3~5mm, 5~10mm, 10~20mm, 20~30mm a...

Embodiment 2

[0059] Example 2 Comparison of combined ultra-thin and long-life pavement structures

[0060] 1. Advantages of pavement structure composition

[0061] The typical combined long-life asphalt pavement and the combined long-life asphalt pavement are selected for comparative analysis. The pavement structure is shown in Table 6. The total thickness of the full-thickness ultra-thin long-life pavement is only 81.0% and 41.5% of that of Structures II and III. Reduced thickness of long-life pavement.

[0062] Table 6 Pavement structure and thickness

[0063]

[0064] 2. Cost advantage of pavement structure

[0065] Taking a highway with a length of 1km and a width of 25m as an example, according to the current market price of materials, the amount and cost of various materials for the three types of pavement structures proposed in Table 6 are calculated. The calculation results are shown in Table 7.

[0066] Table 7 Quantity and cost of three kinds of pavement structural material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com