Rotary power transmission clutch and two-gear speed change regulator

A second-speed variable speed, rotary power technology, applied in transmission control, instruments, controlled components, etc., can solve the problems of high manufacturing cost, limited application, strong use pertinence, etc., to achieve simple and convenient control and operation, and a wide range of applications. , the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

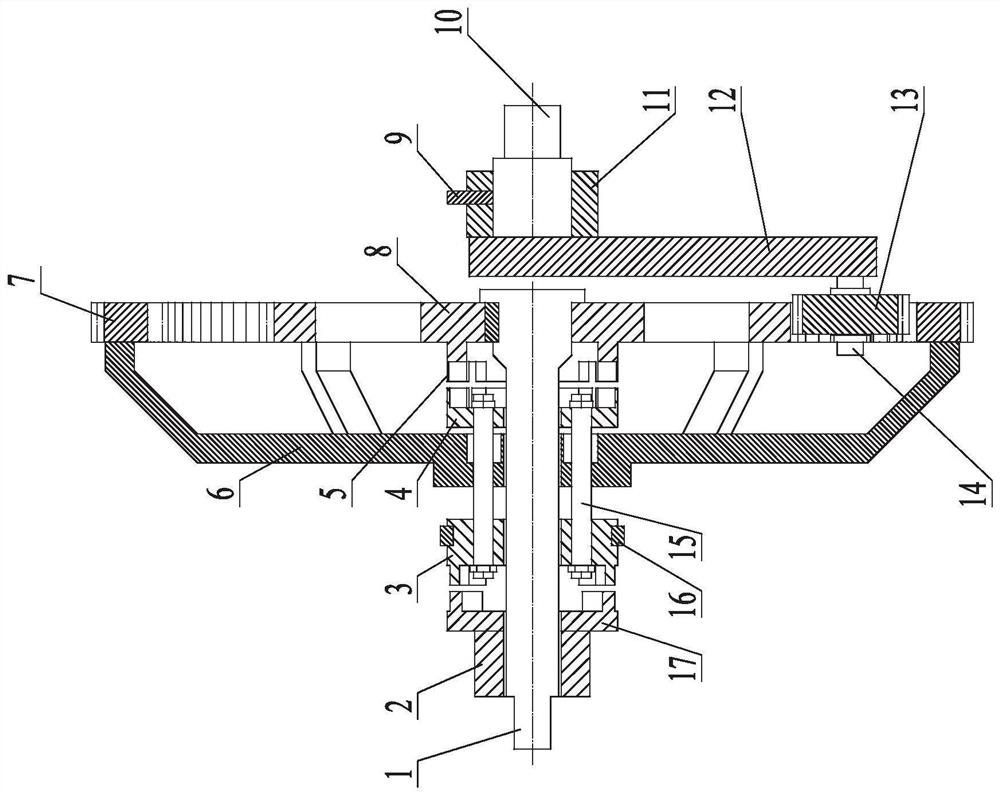

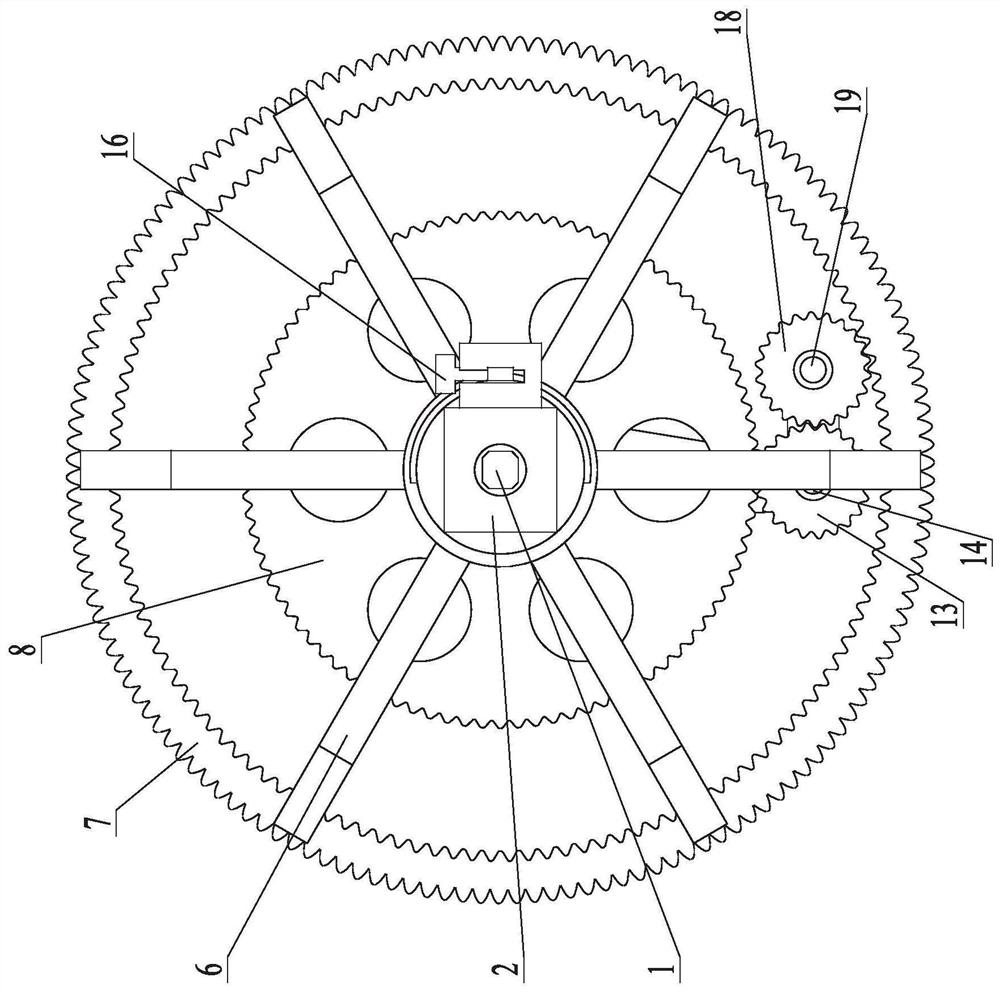

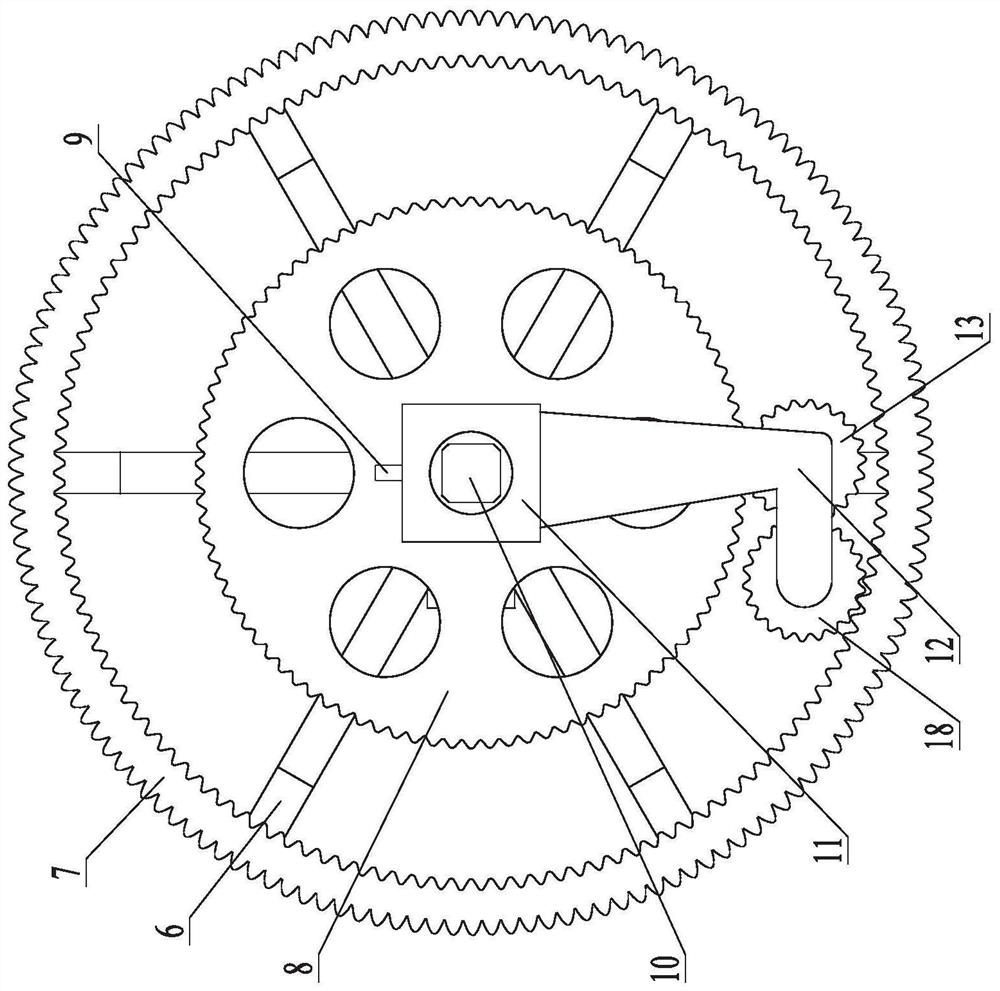

[0014] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A rotary power transmission clutch and second-speed speed change controller, on a fixedly configured mounting base 2, axially and radially positioned, and circumferentially rotatably inserted into a power input shaft 1, on which the power input shaft 1 is located on the mounting base 2 On the right side, from left to right, the clutch sleeve D17, clutch sleeve C3, driving and locking frame 6, clutch sleeve B4, clutch sleeve A5, and central gear 8 are installed sequentially. The clutch sleeve D17 and the power input shaft 1 are relatively rotatable The ground sleeve fits, and the clutch sleeve D17 is fixedly connected with the mounting seat 2. The clutch sleeve C3 and the clutch sleeve B4 are radially positioned, axially movable left and right, and circumferentially relatively rotatable and sleeved on the power input shaft 1. The driving and locking frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com