Pressure vessel pipeline sealing vibration isolation device and working principle thereof

A technology for sealing pressure vessels and pipes, which is applied in the installation device of container structure, container filling method, container discharge method, etc., can solve the problems of poor support stability, poor sealing effect, large vibration amplitude, etc., and achieve slow vibration amplitude, Guarantee stability and ensure the effect of vibration isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

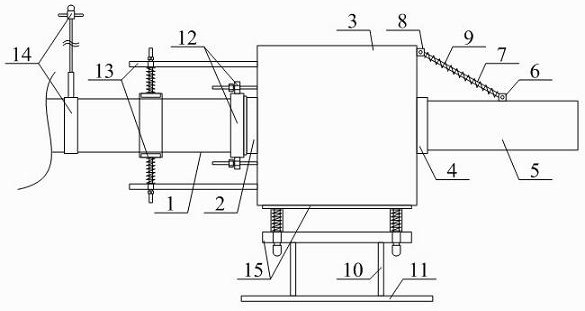

[0040] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

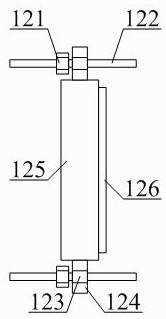

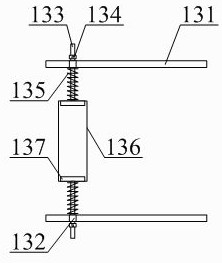

[0041] As shown in accompanying drawing 1 and accompanying drawing 2, a kind of pressure vessel pipeline seal vibration isolation device comprises input pipeline 1, input pipe head 2, pressure vessel body 3, output pipe head 4, output pipe 5, connecting seat 1 6, Buffer pull rod 7, connecting seat 2 8, buffer spring 9, support rod 10, support base 11, adjustable locking seal ring structure 12, vibration isolation and shock absorbing buffer support structure 13, suspension type anti-sagging stay rope structure 14 and Support the buffering and stabilizing seat structure 15, the right end of the input pipe 1 is threadedly connected to the left inlet of the pressure vessel body 3 through the input pipe head 2; the right outlet of the pressure vessel body 3 is threaded through the output pipe head 4 The left end of the output pipeline 5; the upper part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com