Sampling device for water quality detection

A sampling device and water quality detection technology, applied in the direction of sampling devices, etc., can solve the problems of lack of impurities in filtering devices, troublesome sampling work, blockage of sampling devices, etc., and achieve the effects of improving stability, convenient operation, and convenient for later use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

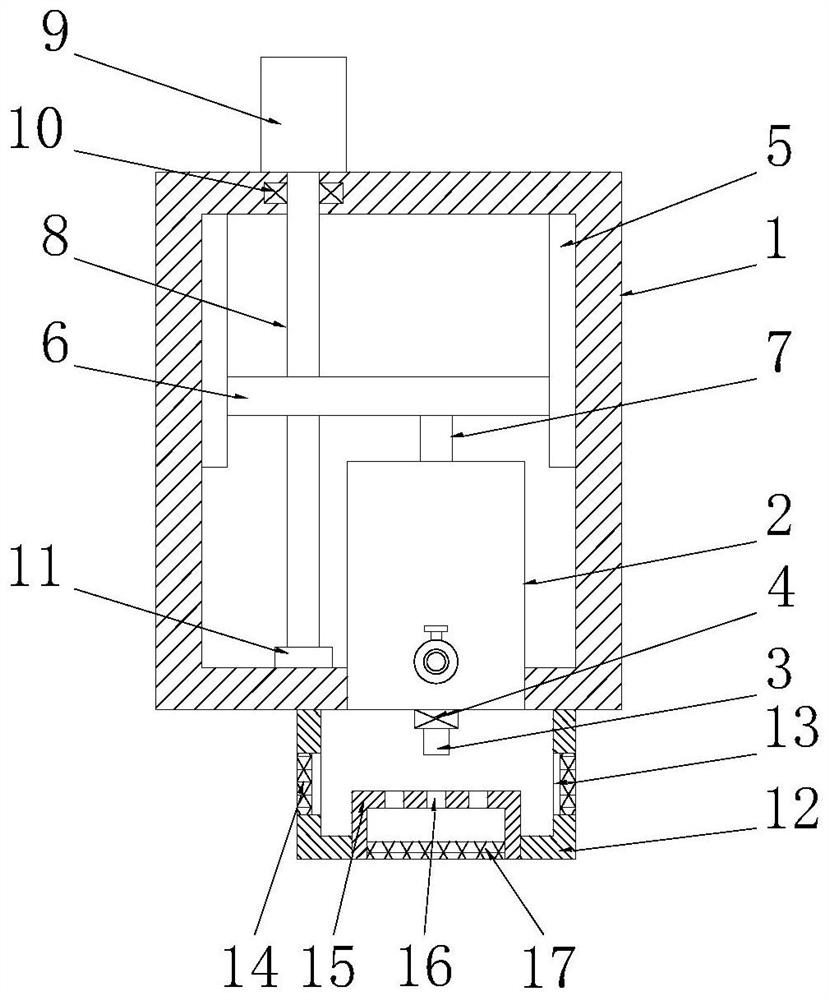

[0020] See figure 1 , a sampling device for water quality detection, comprising a bracket 1, the bracket 1 is a rectangular frame structure, a sampling cylinder 2 is embedded on one side of the bottom wall of the inner cavity of the bracket 1, and the bottom end of the sampling cylinder 2 is connected to the water inlet pipe 3. A one-way valve 4 is installed on the water inlet pipe 3. A filter box 12 is provided at the bottom end of the bracket 1. The filter box 12 is sleeved on the outside of the water inlet pipe 3. The bottom end of the filter box 12 is embedded There is a water inlet cylinder 15, the water inlet cylinder 15 is a cylindrical structure with an open bottom, the bottom opening of the water inlet cylinder 15 is provided with a second filter screen 17, and the top of the water inlet cylinder 15 is uniformly provided with a number of through holes 16, so The side wall of the filter box 12 is uniformly connected with some water inlet holes 13, and the first filter ...

Embodiment 2

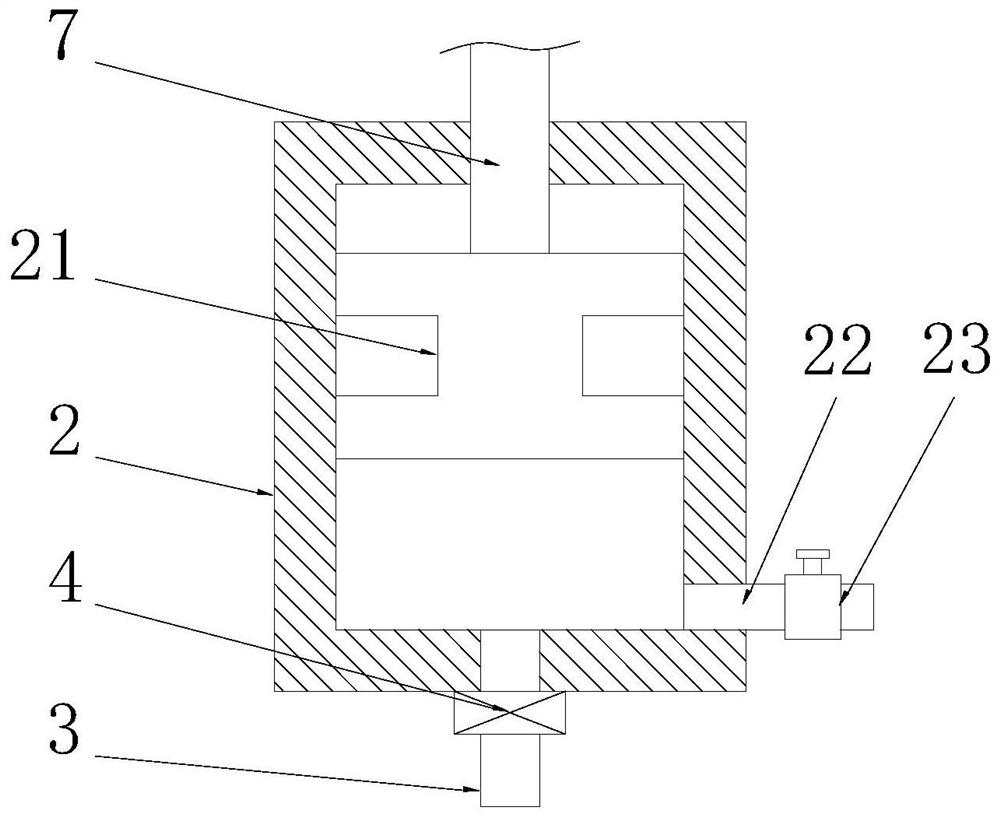

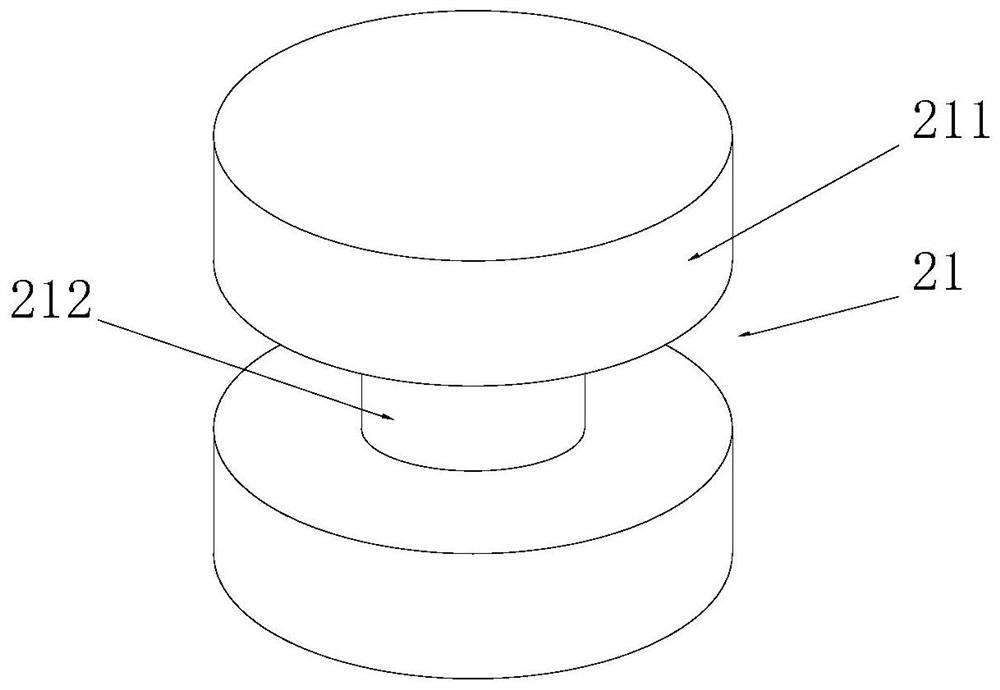

[0022] See Figure 1-3 The difference from Example 1 is that guide rails 5 are symmetrically arranged on the left and right sides of the inner cavity of the bracket 1, and the guide rails 5 are T-shaped guide rails, and a push plate 6 is slidably connected between the two guide rails 5. The bottom end of the push plate 6 is fixedly connected with the push rod 7 matched with the sampling cylinder 2, the push plate 6 is embedded with a screw rod 8, and the push plate 6 and the screw rod 8 are threaded, and the connection between the screw rod 8 and the guide rail 5 The relationship between them is parallel to each other. The top end of the screw rod 8 runs through the top wall of the bracket 1 and is rotatably connected to the propulsion motor 9. The bottom end of the screw rod 8 is rotatably connected to the bracket 1 through the bearing seat 11. On the bracket 1, the inner cavity of the sampling cylinder 2 is slidably connected with a piston 21, and the bottom end of the push ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com