A vertical assembly device for the same groove of the rotor magnets of the permanent magnet motor of the rail transit

A permanent magnet motor and rail transit technology, applied in the field of rail transit permanent magnet motor rotor magnetic steel vertical assembly device in the same groove, to achieve the effect of easy type change, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

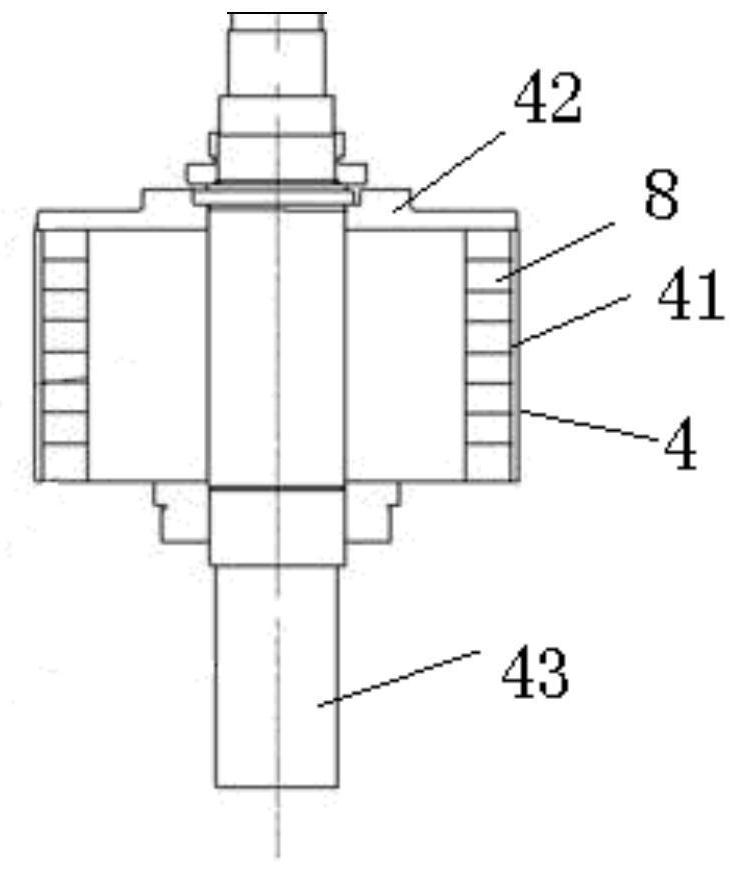

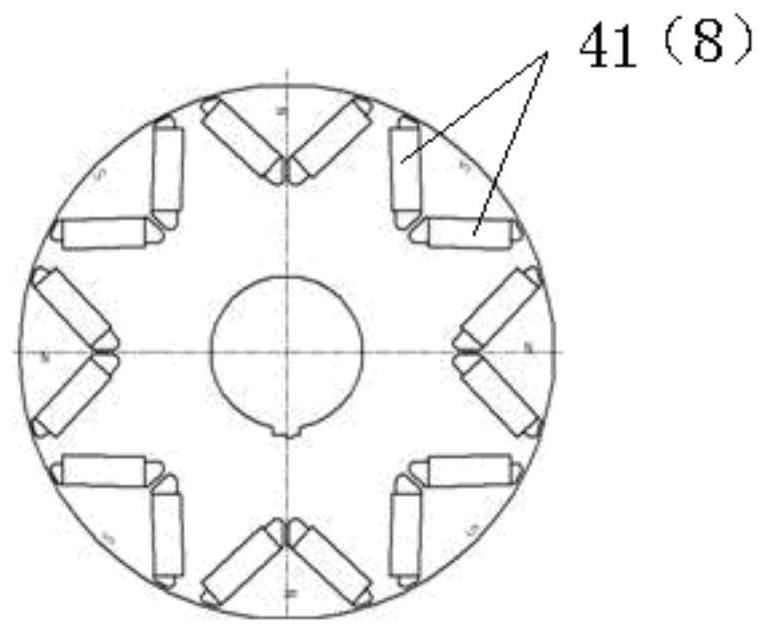

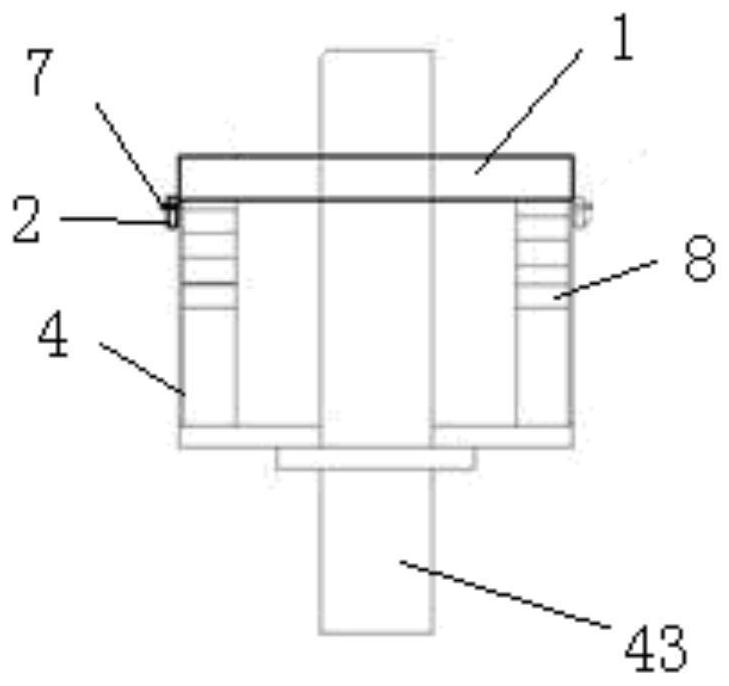

[0024] like Figure 3 to Figure 5 As shown in the figure, the vertical assembly device for the magnetic steel of the rotor of the permanent magnet motor for rail transit in this embodiment includes a magnetic steel assembly guide mold 1 and an iron ring 2, and the magnetic steel assembly guide mold 1 is provided with a plurality of magnetic steels along the circumferential direction. Slot 3, the two sides of the magnetic steel slot 3 are respectively provided with a first auxiliary slot 51 and a second auxiliary slot 52. The first auxiliary slot 51 and the second auxiliary slot 52 are connected with the magnetic steel slot 3. The first auxiliary slot There is a first iron block 61 in the 51, a second iron block 62 is arranged in the second auxiliary groove 52, the width of the first iron block 61 and the second iron block 62 in the circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com