Cigarette paper conveying paper scrap cleaning and stacking device

A technology for cigarette paper and paper foam is applied in the field of cigarette paper conveying and paper foam cleaning and stacking devices, which can solve the problems of increased labor intensity, cluttered on-site environment, health effects of breathing paper foam, etc., and achieves increased labor intensity and improved work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

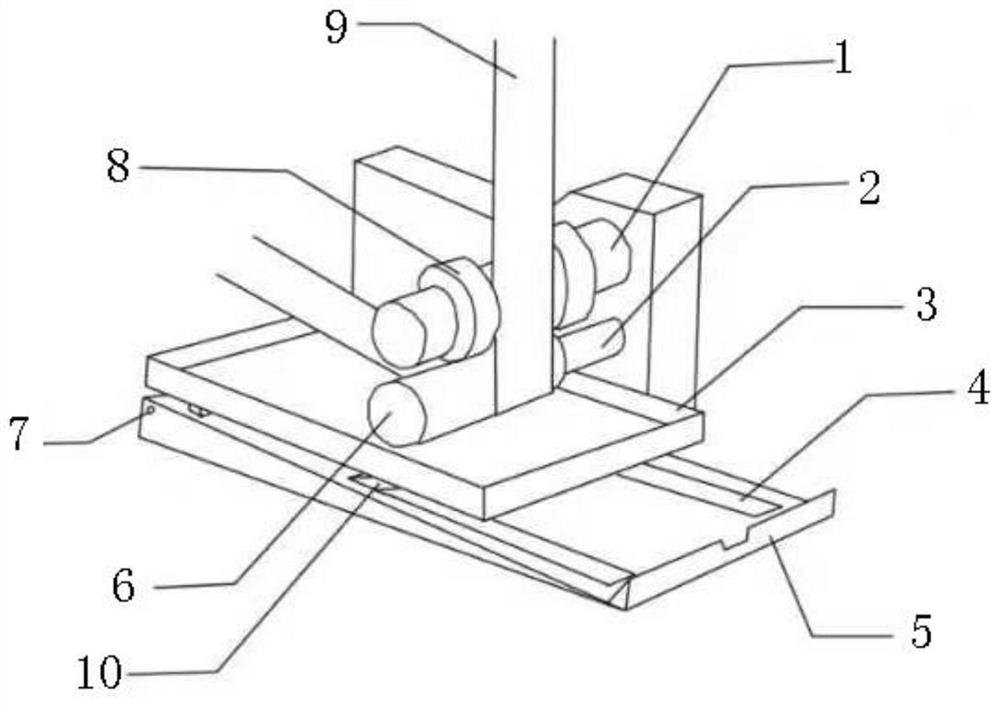

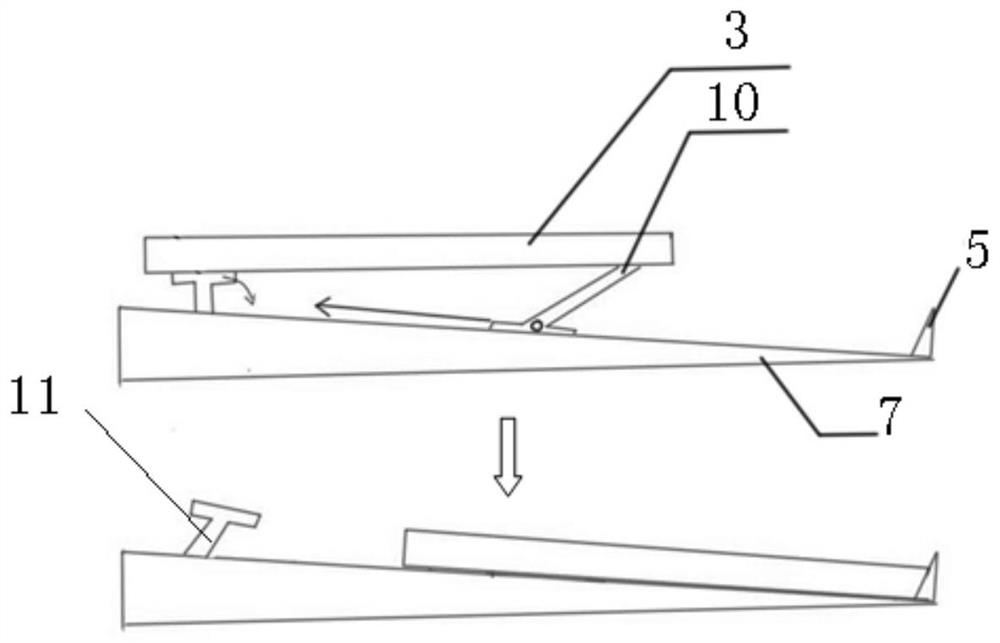

[0021] like figure 1 As shown, the present application provides a cigarette paper conveying paper foam cleaning and stacking device, including a cigarette paper conveying roller shaft 2, and the cigarette paper 9 is conveyed to the required work through the cigarette paper conveying roller 6 installed on the cigarette paper conveying roller shaft position, a fixed roller 1 is arranged above the cigarette paper conveying roller, and two opposite radial projections are arranged on the fixed roller to form a fixed stopper 8 for preventing deviation of cigarette paper conveying, and the cigarette paper is conveyed between the two cigarette ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com