Welding device and method for microchannel liquid-cooled cold plate

A welding device and micro-channel technology, applied in welding equipment, arc welding equipment, milling machine equipment, etc., can solve problems such as liquid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

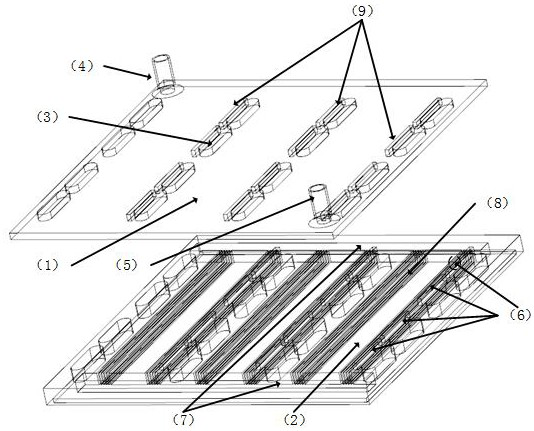

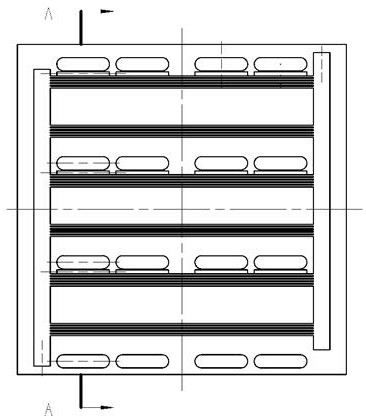

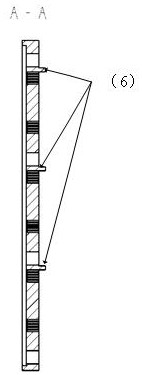

[0026] like figure 1 , Figure 2A , Figure 2B , Figure 3A , Figure 3B Shown, a kind of welding device of the liquid cold plate of microchannel is characterized in that: at least comprise microchannel substrate 2 and cover plate 1, described microchannel substrate 2 and cover plate 1 have identical area and shape, in the same The position of the microchannel substrate 2 and the cover plate 1 respectively have 4 rows of cable connector via holes 3, each row of cable connector via holes 3 has 4, and the side of the cover plate 1 has a through groove 9 on the side of the 3 rows of cable connector via holes , there are bosses 6 on one side of the three rows of cable connector holes arranged side by side on the microchannel substrate 2, and the through grooves 9 are used on the cover plate 1 to cooperate with the bosses 6 of the microchannel substrate 2, and the bosses 6 are on the microchannel substrate 2 Welding weak points are designed; there are coolant inflow riser 4 and...

Embodiment 2

[0038] see figure 1 , Figure 2A , Figure 2B , Figure 3A , Figure 3B , a welding device for a liquid-cooled plate of a microchannel, characterized in that: at least including a microchannel substrate 2 and a cover plate 1, the microchannel substrate 2 and the cover plate 1 have the same area and shape, and at the same position The microchannel substrate 2 and the cover plate 1 respectively have 4 rows of cable connector via holes 3, and each row of cable connector via holes 3 has 5, and the side of the 3 rows of cable connector via holes arranged side by side on the cover plate 1 has a through groove 9. There are bosses 6 on one side of the three rows of cable connectors arranged side by side on the channel substrate 2, and the through grooves 9 are used to cooperate with the bosses 6 of the microchannel substrate 2 on the cover plate 1. The welding of the bosses 6 on the microchannel substrate 2 is weak. design; at the two opposite corners of the cover plate 1 there ar...

Embodiment 3

[0041] see figure 1 , Figure 2A , Figure 2B , Figure 3A , Figure 3B, a welding device for a liquid-cooled plate of a microchannel, characterized in that: at least including a microchannel substrate 2 and a cover plate 1, the microchannel substrate 2 and the cover plate 1 have the same area and shape, and at the same position The microchannel substrate 2 and the cover plate 1 have m columns of cable joint via holes 3 respectively, and each column of cable joint via holes 3 has n, and the m and n are not greater than 5, when m=3, n=3, wherein There are through grooves 9 on one side of the three rows of cable connector holes arranged side by side on the cover plate 1, and there are bosses 6 on one side of the three rows of cable connector holes arranged side by side on the microchannel substrate 2. The boss 6 of the channel substrate 2 is used together, and the boss 6 is designed at the welding weak point of the microchannel substrate 2; there are cooling liquid inflow ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com