Barreling device

A technology of rolling and grinding mechanism, which is applied in the field of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

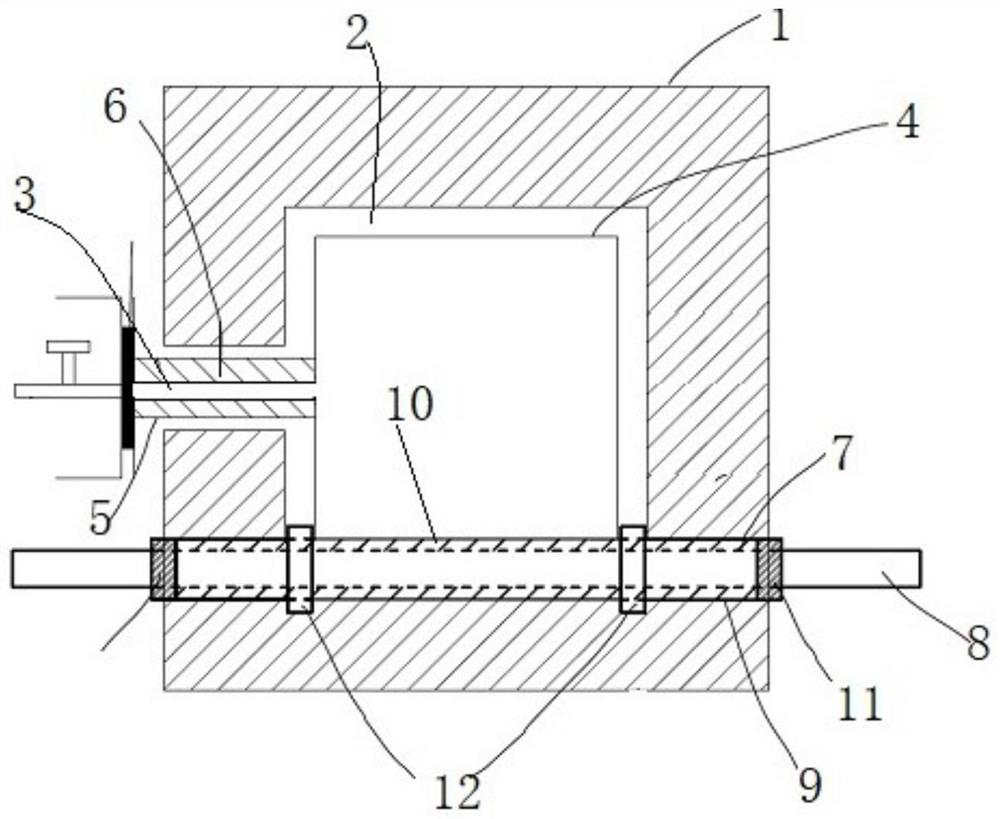

[0033]The technical solution of the present invention will be apparent from the accompanying drawings and examples. Based on the embodiments of the present invention, those of ordinary skill in the art will belong to the scope of the present invention without paying in the premise of creative labor.

[0034]The inventors have been studied and the actual operation has been found: the existing tank mill function is single, only for material grinding, can not meet multi-conditioned grinding requirements, especially in the development or production process, according to material characteristics, there is usually more abrasive conditions. Demand, such as heating function, vacuum function, designated atmosphere protection function, etc.

[0035]Existing grinders can only be carried out separately from material grinding and heat treatment, and they cannot synchronize the material, and there are many limitations in production or research. Further, in order to solve the above technical problems, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com