Explosion-proof fire robot

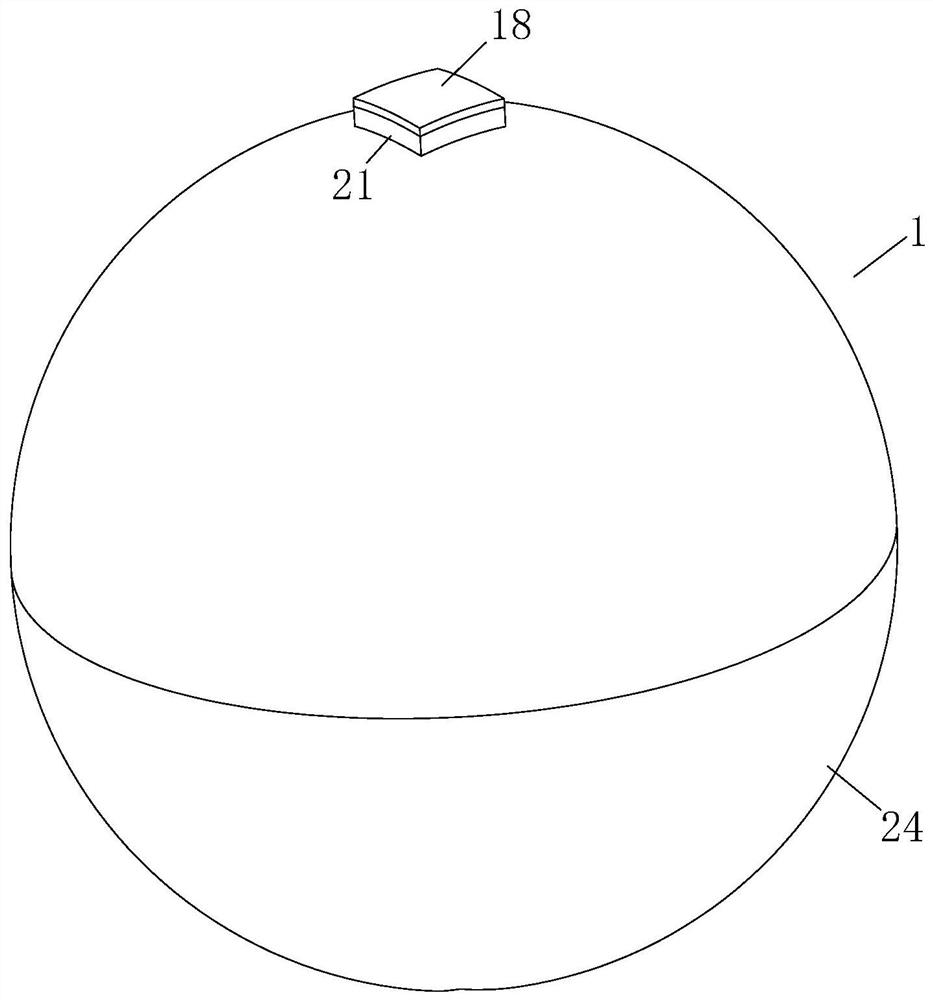

A fire-fighting robot and shell technology, which is applied in the field of robots, can solve the problems of tipping and rollover, affecting the effective survey of the fire site by the robot, etc., and achieves the effect of convenient disassembly and installation, convenient rolling and reset, and improved use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

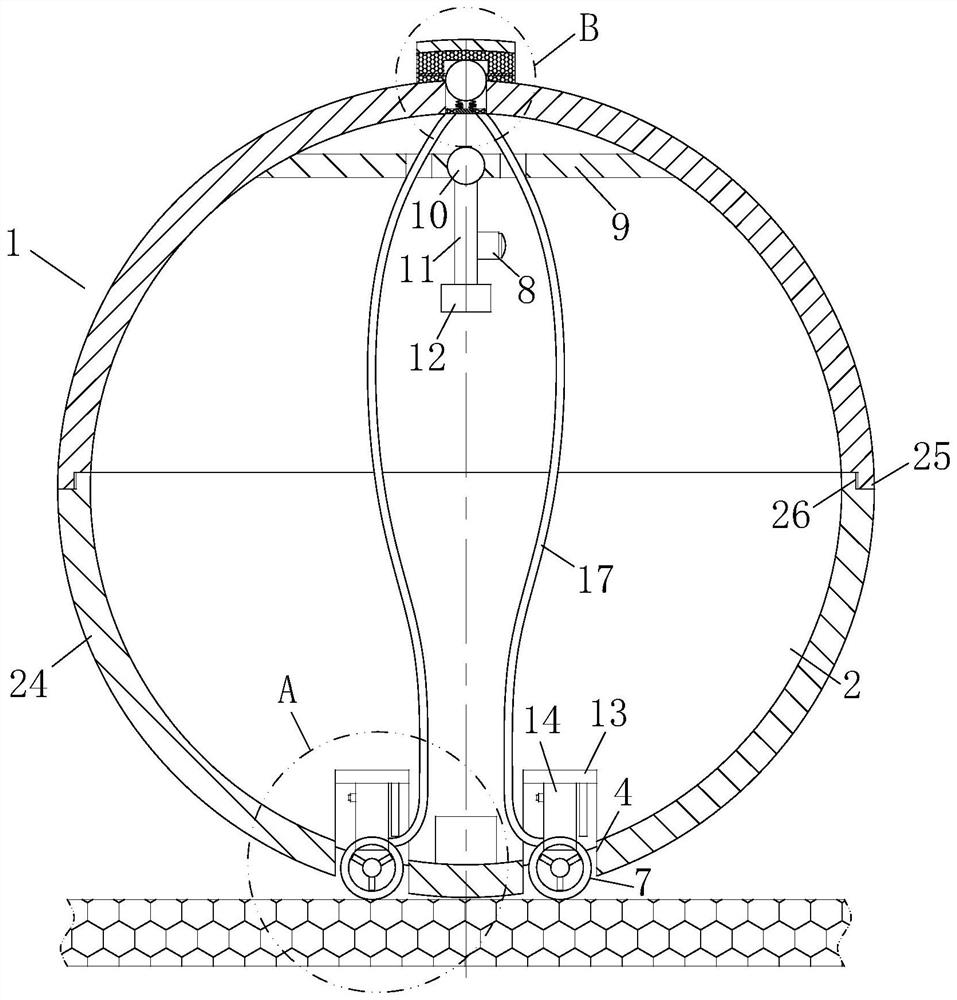

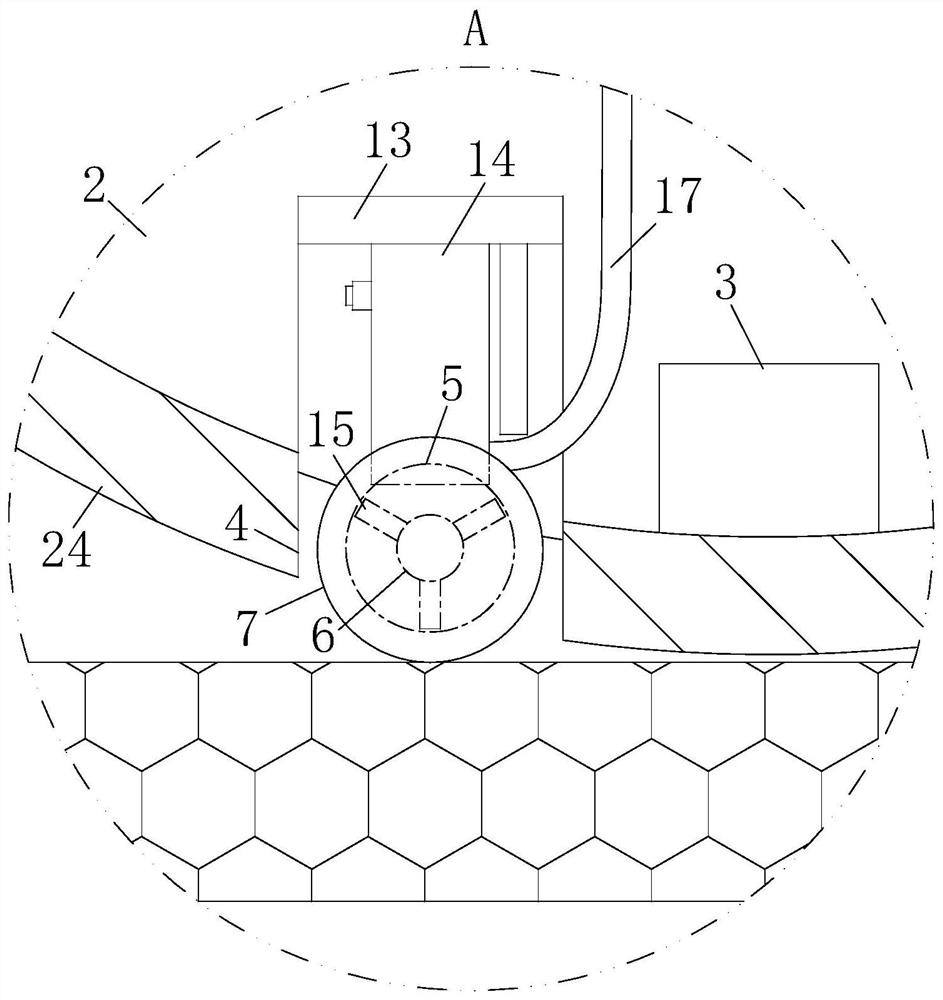

[0027] As an embodiment of the present invention, a balance plate 9 is provided inside the housing 1, and a turning groove is arranged inside the balance plate 9, and a rotating ball 10 is rotatably connected in the turning groove, and the bottom of the rotating ball 10 is There is a connecting rod 11 at the end, and the bottom end of the connecting rod 11 is provided with a gravity block 12, and the camera 8 is installed on the connecting rod 11; when working, when the housing 1 is skewed, the connecting rod 11 set at this time is in the Under the action of the gravity block 12, the rotating ball 10 is driven to rotate inside the rotating groove, so that the connecting rod 11 is always in a vertical state, so that the camera 8 on the connecting rod 11 can stably shoot the fire scene, preventing the housing 1 from moving Shaking or skewing during the process causes the camera 8 to shake or skew synchronously, thereby affecting the stable shooting of the fire scene by the camera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com