A Sydney paper packaging machine equipment

A Sydney and equipment technology, which is applied in the field of Sydney paper packaging machine equipment, can solve the problems of easily wrinkled Sydney paper, affecting production efficiency, damage, etc., and achieve the effects of short debugging time, improved packaging efficiency, and reduced failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to specific embodiments and accompanying drawings.

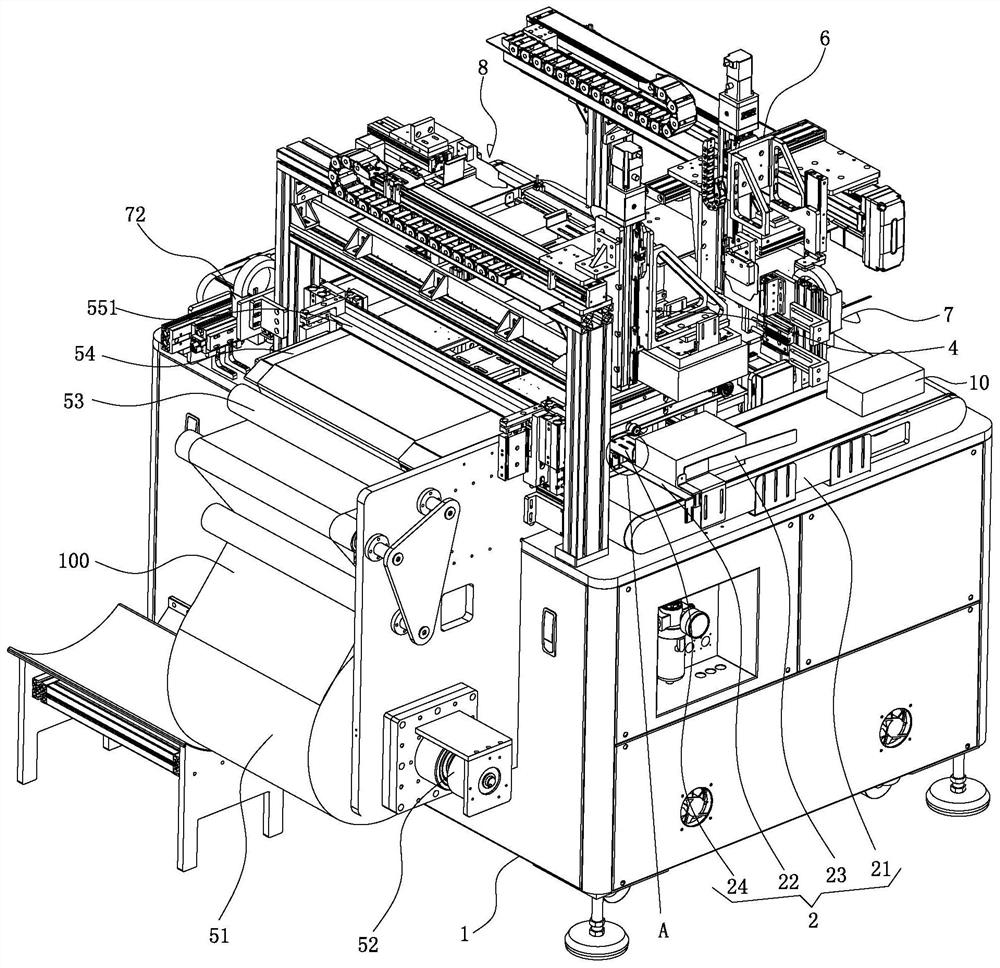

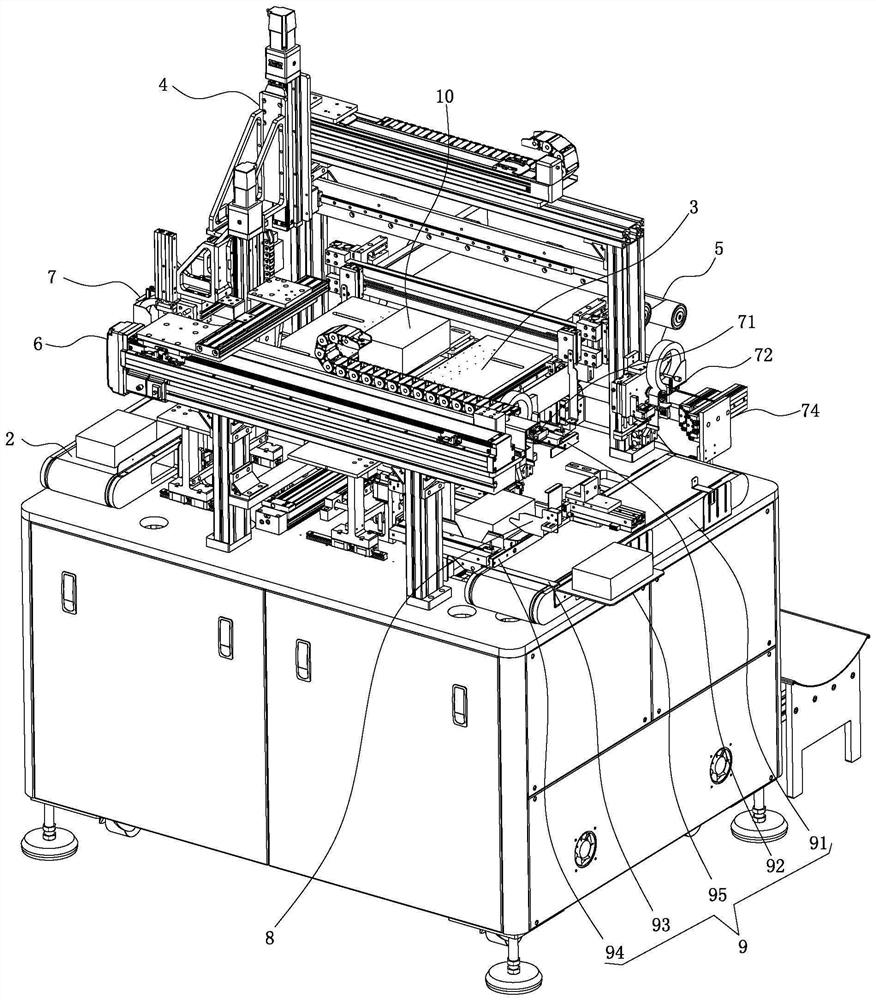

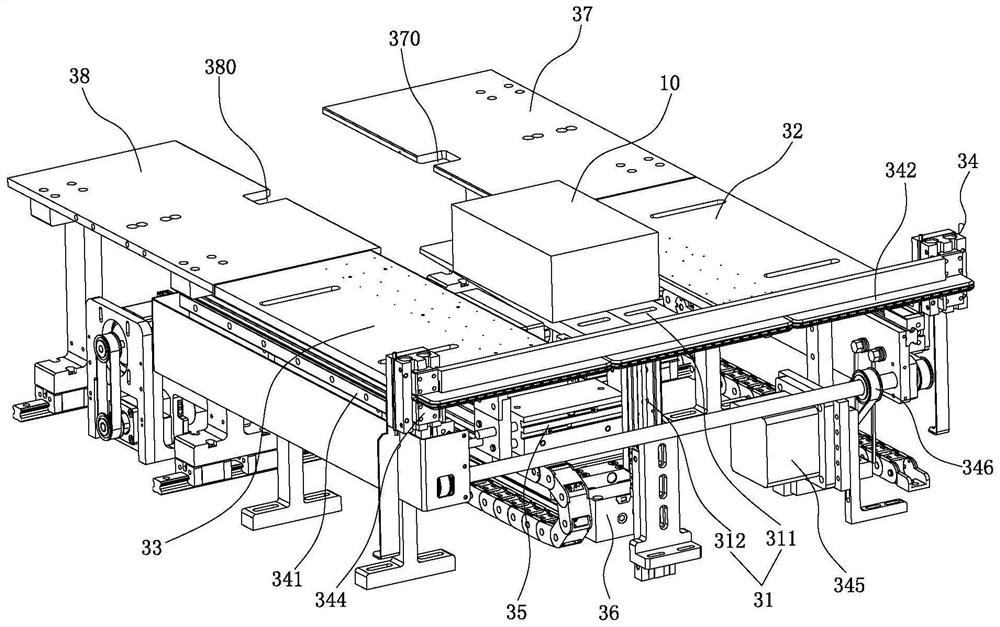

[0029] See Figure 1 to Figure 12As shown, it is a Sydney paper packaging machine equipment, which includes: a feeding and conveying mechanism 2 for conveying products 10, which is arranged beside the feeding and conveying mechanism 2 and is used for folding and packaging Sydney paper 100 to the products. The long-side folding mechanism 3 on the 10, the first transfer mechanism 4 for transferring the product 10 from the feeding conveying mechanism 2 to the long-side folding mechanism 3, and a first transfer mechanism 4 arranged on the long-side folding mechanism 3 A Sydney paper feeding mechanism 5 for supplying the Sydney paper 100, a second transfer mechanism 6 provided on the other side of the long-side folding mechanism 3, and a first adhesive tape provided at one end of the second transfer mechanism 6 A sealing mechanism 7, a short-edge folding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com