A bearing ring expansion fixture

A bearing ring and expansion type technology, which is applied in the field of bearing ring expansion type fixtures, can solve the problems of long tightening and loosening time and complicated fixture adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

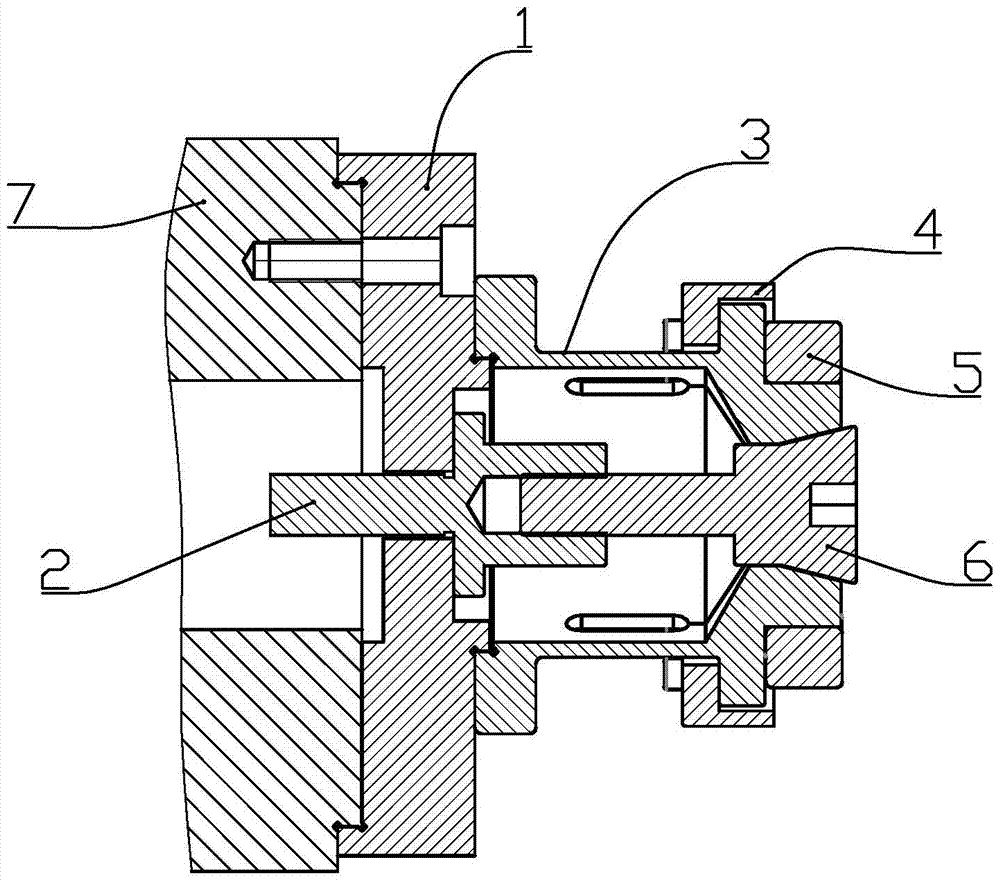

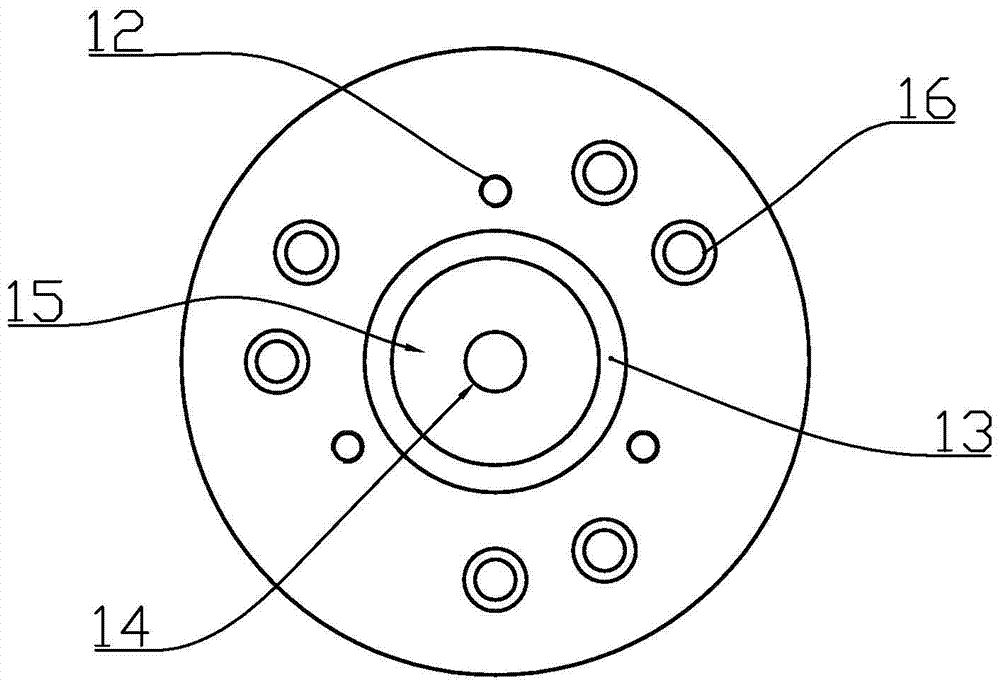

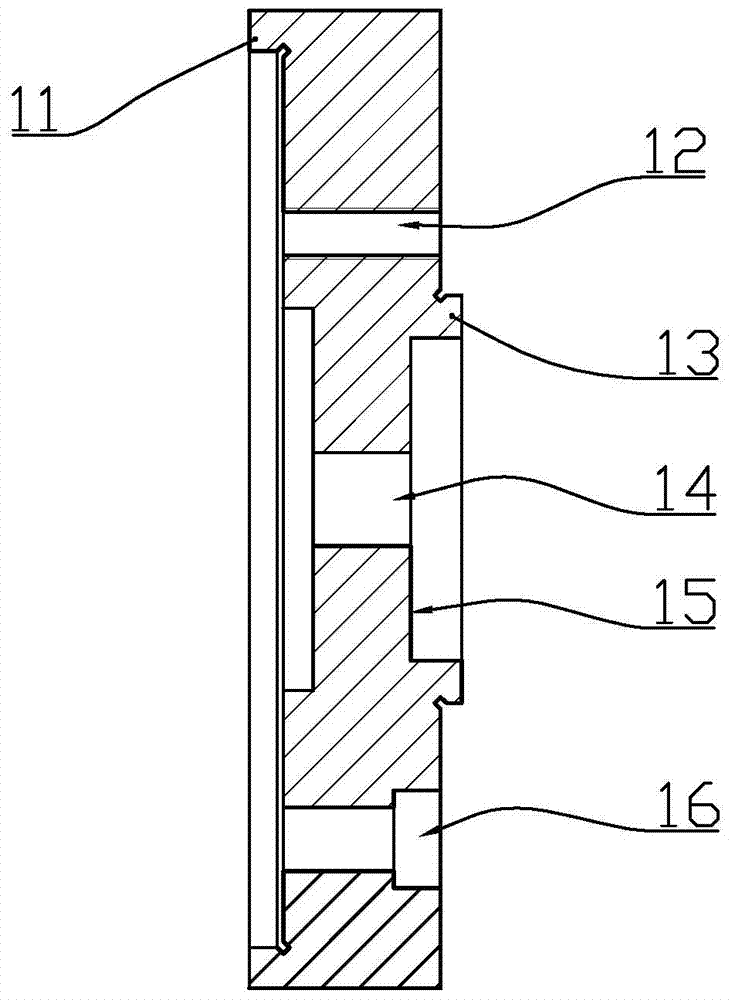

[0034] A detailed description will be given below of specific embodiments of the present invention according to the accompanying drawings.

[0035] according to Figure 1 to Figure 14 As shown, this embodiment is a bearing ring expansion fixture, including a transition plate 1 connected to the machine tool spindle 7, a collet seat 3 connected to the transition plate, and a positioning ring 4 installed on the collet seat and jaw 5;

[0036] The chuck seat is tubular, the front side of the chuck seat is the claw installation part for installing the jaws, and the fixed shoulder 32 for installing the positioning ring is formed on the rear side of the jaw installation part on the chuck seat;

[0037] The front wall of the chuck seat is equidistantly provided with six cut grooves 36 along the axial direction, and the middle part of the chuck seat wall is provided with elliptical grooves 31 corresponding to the positions of the cut grooves;

[0038] The positioning ring 4 is compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com