Goods picking and conveying frame structure for logistics warehouse

A frame structure and frame structure technology, applied in the field of logistics equipment, can solve the problems of easy bumping, difficult to handle, too large items, etc., and achieve the effects of convenient height adjustment, increased transmission torque, and increased stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

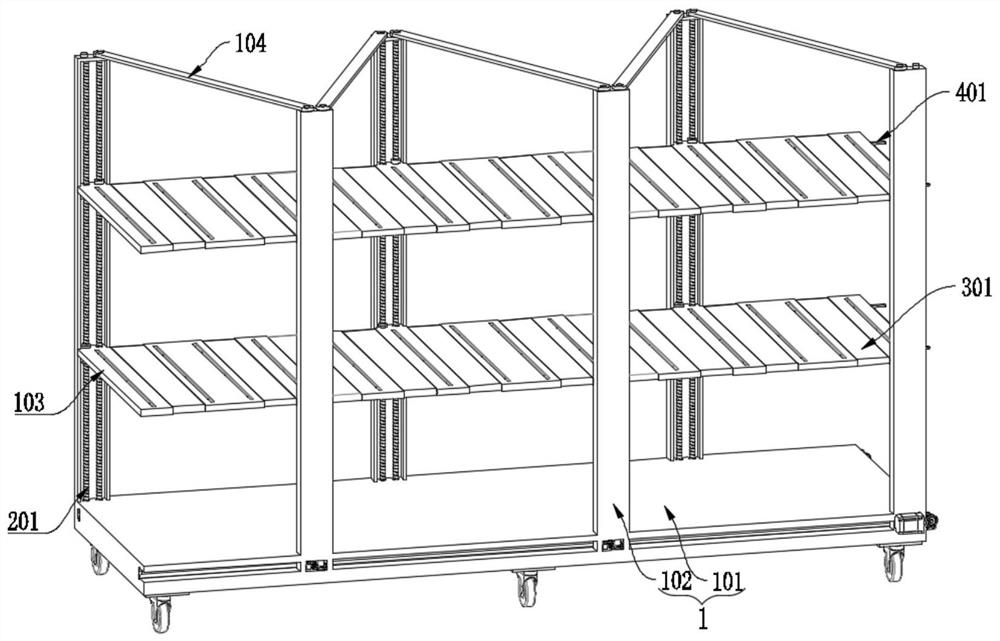

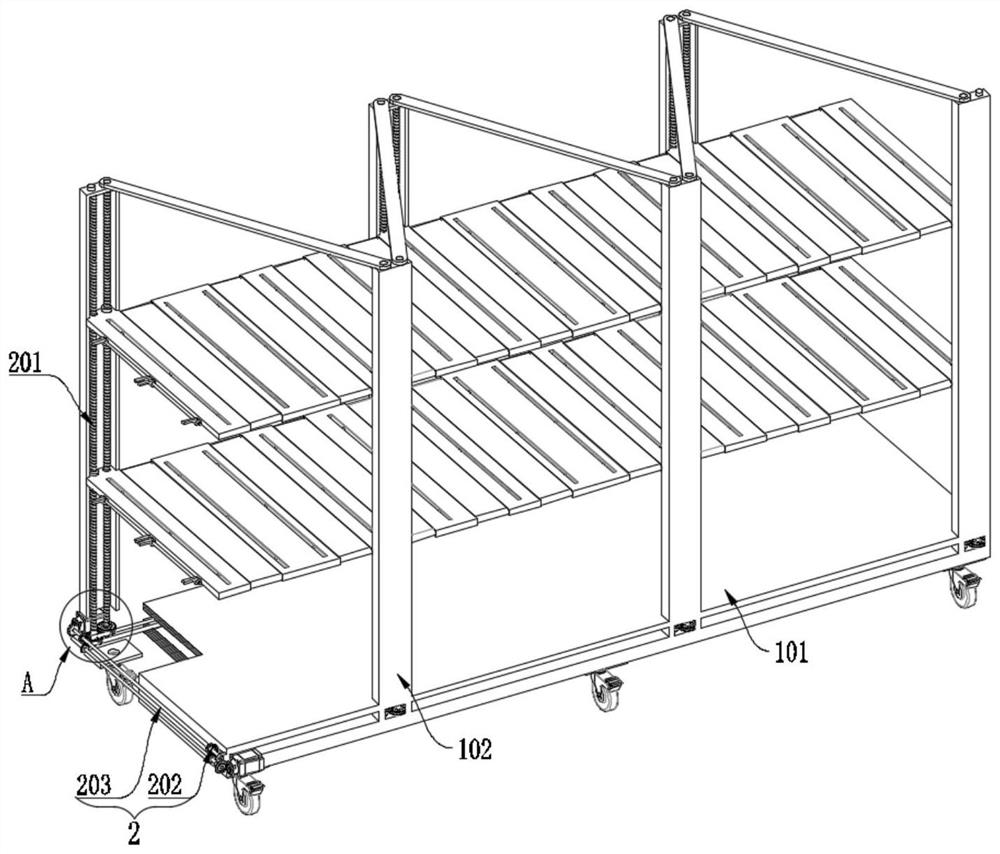

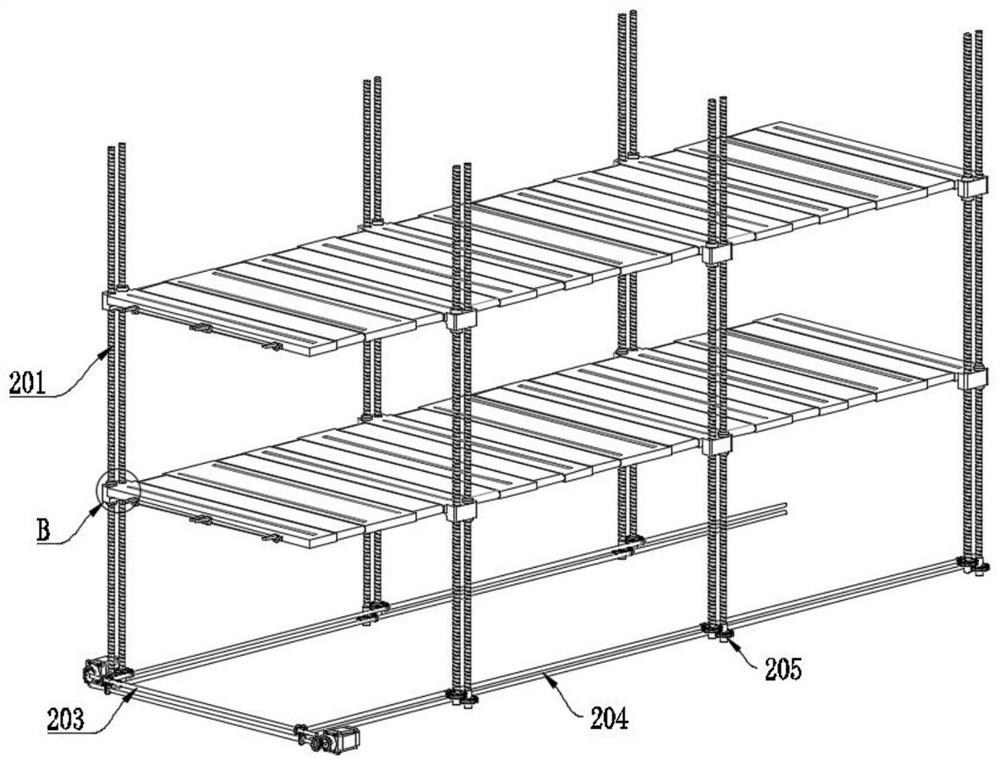

[0036]as attached figure 1 To attach Figure 9 Shown:

[0037] The present invention provides a frame structure for picking and transporting logistics warehouses, including a frame structure 1; a lifting structure 2 is installed on the frame structure 1; a bearing plate 103 is slidably installed on the lifting structure 2; a sliding structure 3 is arranged on the bearing plate 103 ; The loading plate 103 is provided with a mounting groove 106, and a fixed structure 4 is installed at the mounting groove 106; the frame structure 1 also includes a base plate 101, a support rod 102, and a reinforcing rod 104, and the base plate 101 is welded and fixed with a vertical support rod 102, the support bar 102 is made of U-shaped channel steel as a whole, and the top of the support bar 102 is connected with a reinforcing bar 104. Usually, in order to further increase the corresponding load capacity of the shelf, the support bar 102 on the bottom plate 101 is directly welded. The connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com