Tablet printing equipment

A technology for printing equipment and tablets, which can be used in sorting, vibrating conveyors, conveyor objects, etc., and can solve problems such as low efficiency, time-consuming and laborious, and incomplete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

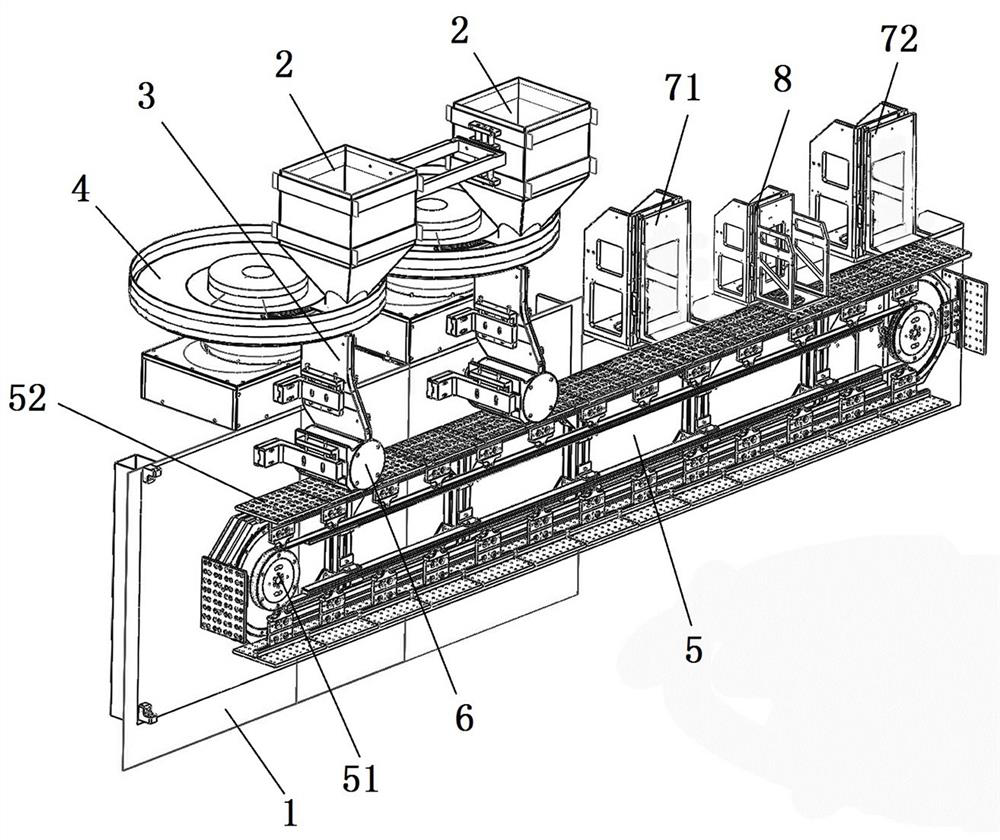

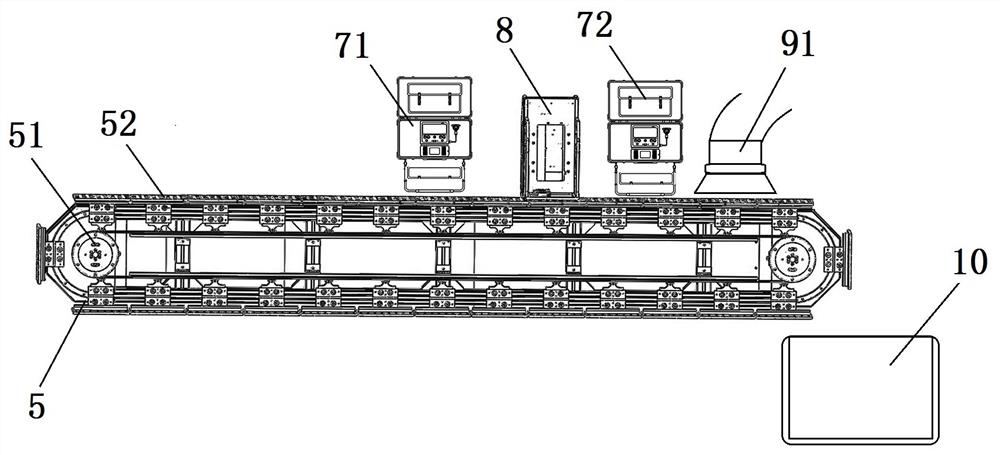

[0029] As shown in Figures 1-9, the present invention proposes a printing device for tablets 11, including two hoppers 2 installed on a frame 1, two vibration plates 4 for sorting tablets 11, a conveying device and a printing device 8 , The hopper 2 is located above the vibration plate 4 . The transmission mechanism includes a horizontal transmission device and two feeding devices 6 , the top of the two feeding devices 6 are respectively connected to the discharge ends of the two vibrating plates 4 through the feeding pipe 3 , and the bottom is connected to the horizontal transmission device. After the disordered tablets 11 in the hopper 2 are sorted by the vibrating plate 4, the neatly sorted tablets 11 are conveyed downwards by the feeding pipe 3 to the feeding device 6 which plays a transitional role, and the tablets 11 are transported by the two feeding devices 6. Neatly falling into the first storage tank 601 in the horizontal conveying device, significantly improving the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap