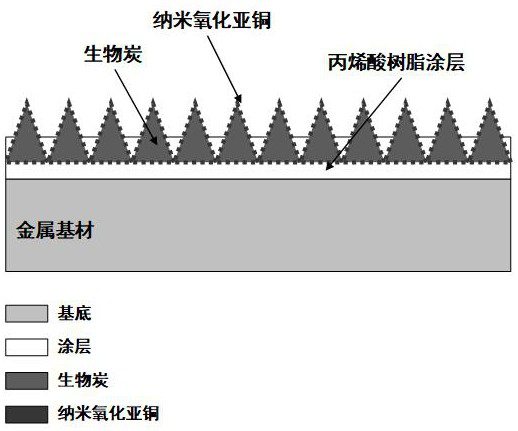

A kind of preparation method of organic-inorganic three-phase composite antifouling coating with spirulina biochar as carrier

A technology of antifouling coatings and biochar, applied in antifouling/underwater coatings, biocide-containing paints, coatings, etc., can solve the problems of inability to exert nanoscale cuprous oxide, reduce use efficiency, and poor dispersion. Achieve the effects of low cost, enhanced mechanical durability, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

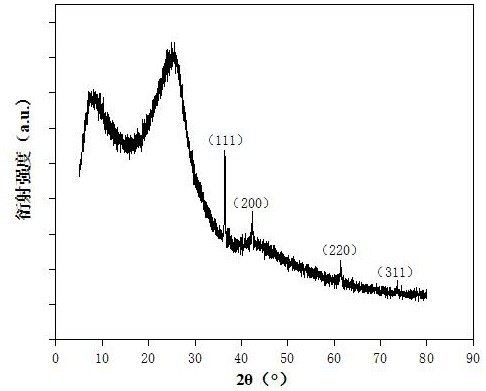

[0026] Example 1 (1) Soak Spirulina powder in 0.4 mol·L -1 In dilute hydrochloric acid, stirred at 500 rpm for 20 h, washed three times with deionized water, once with absolute ethanol, and dried. The dried solid was fully ground into powder, and in an argon atmosphere, at a heating rate of 5 °C·min -1 , heated to 600 °C, pyrolyzed for 2.5 h, cooled, taken out, and fully ground to obtain spirulina biochar powder.

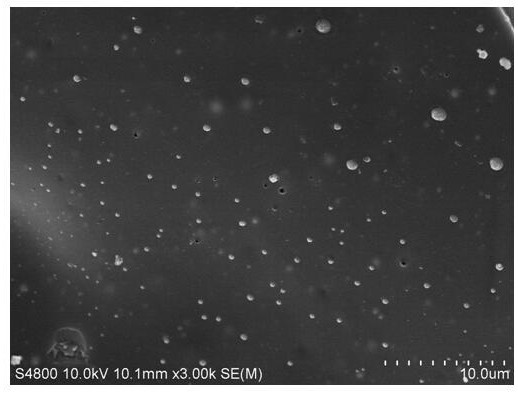

[0027] (2) Add part of the biochar powder into a beaker filled with 40 mL of deionized water, stir at 500 rpm for 30 min, then add copper sulfate pentahydrate and polyvinylpyrrolidone powder with a mass ratio of 2:1, and continue stirring for 30 min , and finally add 10 mL of 0.5 mol·L -1 Sodium hydroxide aqueous solution and 10 mL ascorbic acid aqueous solution, the mass ratio of copper salt to reducing agent was 4:5, stirred and reacted for 1.2 h, the reacted particles were washed three times with water and once with absolute ethanol to obtain a loading capacity...

Embodiment 2

[0033] Example 2 (1) Soak Spirulina powder in 0.6 mol·L -1 In dilute hydrochloric acid, stirred at 800 rpm for 24 h, washed five times with deionized water, washed twice with absolute ethanol, and dried. The dried solid was fully ground into powder, and under an argon atmosphere, the temperature was increased at a rate of 8 °C min -1 , heated to 800 °C, pyrolyzed for 2.0 h, cooled, taken out, and fully ground to obtain spirulina biochar powder.

[0034] (2) Add part of the biochar powder into a beaker filled with 40 mL of deionized water, stir at 500 rpm for 30 min, then add copper sulfate pentahydrate and polyvinylpyrrolidone powder with a mass ratio of 2:1, and continue stirring for 30 min , and finally add 10 mL of 0.5 mol·L -1 Sodium hydroxide aqueous solution and 10 mL ascorbic acid aqueous solution, the ratio of copper salt to reducing agent is 4:5, stirred and reacted for 1.0 h, and the reacted particles were washed 5 times with water and 2 times with absolute ethanol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com