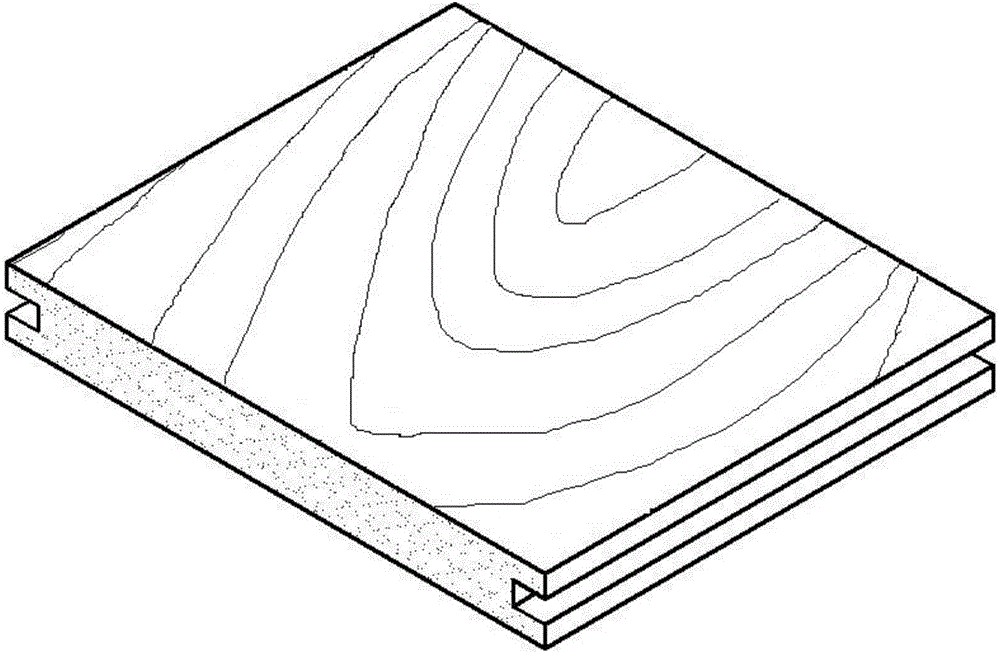

Imitation natural wood grain wood-plastic section and preparation method thereof

A wood-plastic profile, imitating natural technology, applied in the field of new polymer materials, can solve the problems of product performance impact, product expansion, time-consuming and labor-intensive, and achieve the effect of retaining the protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

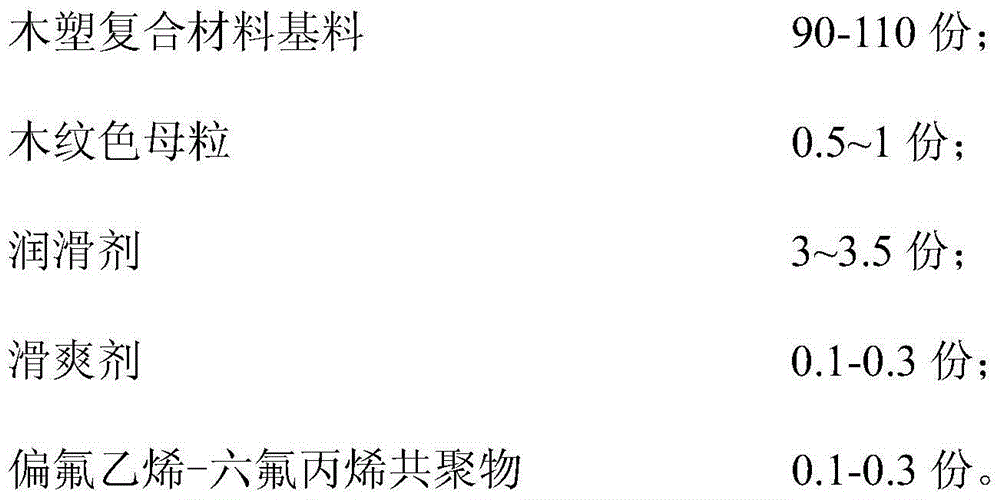

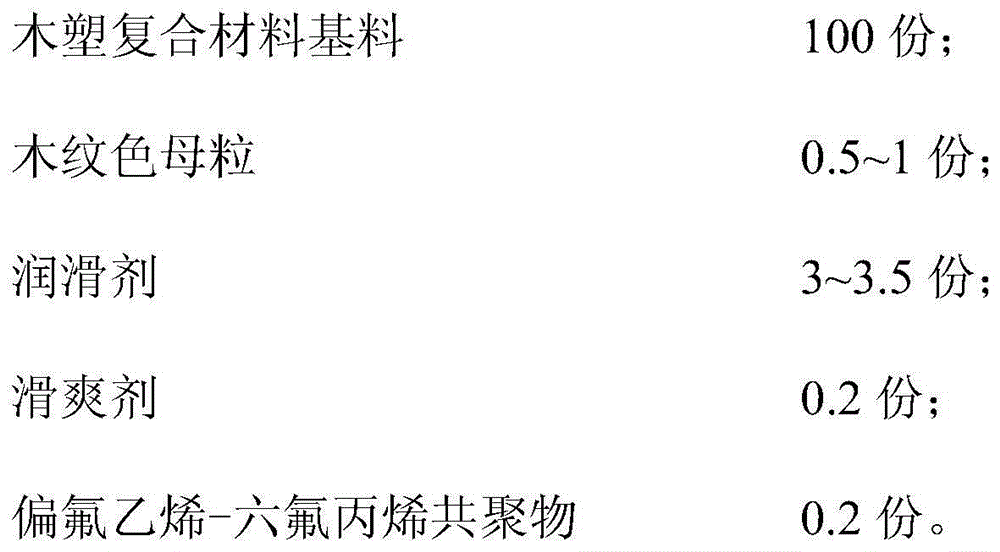

[0036] A wood-plastic profile imitating natural wood grain, including the following raw materials in parts by mass:

[0037]

[0038]

[0039] A preparation method for imitating natural wood-grain wood-plastic profile comprises the following steps:

[0040] a) Weigh the following raw materials according to the wood-plastic composite base material formula:

[0041]

[0042] Add the above-mentioned raw materials into a high-speed mixer, mix at room temperature for 30 minutes, and then discharge them into the hopper of a parallel twin-screw granulator, then add them into the granulator from the feeding system to heat and plasticize, and the obtained uniformly plasticized material is crushed after air-cooling. For base material of wood-plastic composite material, the plasticizing section is in Zone 2 to Zone 7; among them, the heating temperature is:

[0043] a district

Second District

Third District

Four districts

five districts

District...

Embodiment 2

[0055] A wood-plastic profile imitating natural wood grain, including the following raw materials in parts by mass:

[0056] a) Weigh raw materials according to the following parts by mass:

[0057]

[0058]

[0059] A preparation method for imitating natural wood-grain wood-plastic profile comprises the following steps:

[0060] a) Weigh the following raw materials according to the wood-plastic composite base material formula:

[0061]

[0062] Put the above-mentioned raw materials into the high-speed mixer, mix them coldly for 20 minutes, and then discharge them into the hopper of the parallel twin-screw granulator, and put them into the granulator from the feeding system to heat and plasticize, but no mold is used; Crushing after cooling to obtain base material of wood-plastic composite material;

[0063] Wherein, heating temperature is:

[0064] a district

Second District

Third District

Four districts

five districts

District six...

Embodiment 3

[0076] A wood-plastic profile imitating natural wood grain, including the following raw materials in parts by mass:

[0077]

[0078]

[0079] A preparation method for imitating natural wood-grain wood-plastic profiles, comprising the following steps:

[0080] a) Weigh raw materials according to the following parts by mass:

[0081]

[0082] Add the above-mentioned raw materials into the high-speed mixer, mix them cold for 40 minutes, and then discharge them into the hopper of the parallel twin-screw granulator, and put them into the granulator from the feeding system to heat and plasticize, but no mold is used; Crushing after cooling to obtain base material of wood-plastic composite material;

[0083] Wherein, heating temperature is:

[0084] a district

Second District

Third District

Four districts

five districts

District six

District Seven

eight districts

District 9

100℃

140℃

175℃

175℃

175℃

17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com