An integrated vertical non-metallic sound barrier system and installation method

A sound barrier and non-metallic technology, which is applied in the field of integrated vertical non-metallic sound barrier system and installation, can solve the problems of easy corrosion, loose board body, strip falling off, etc., and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to understand the content of the present invention more clearly, it will be described in detail with reference to the drawings and embodiments.

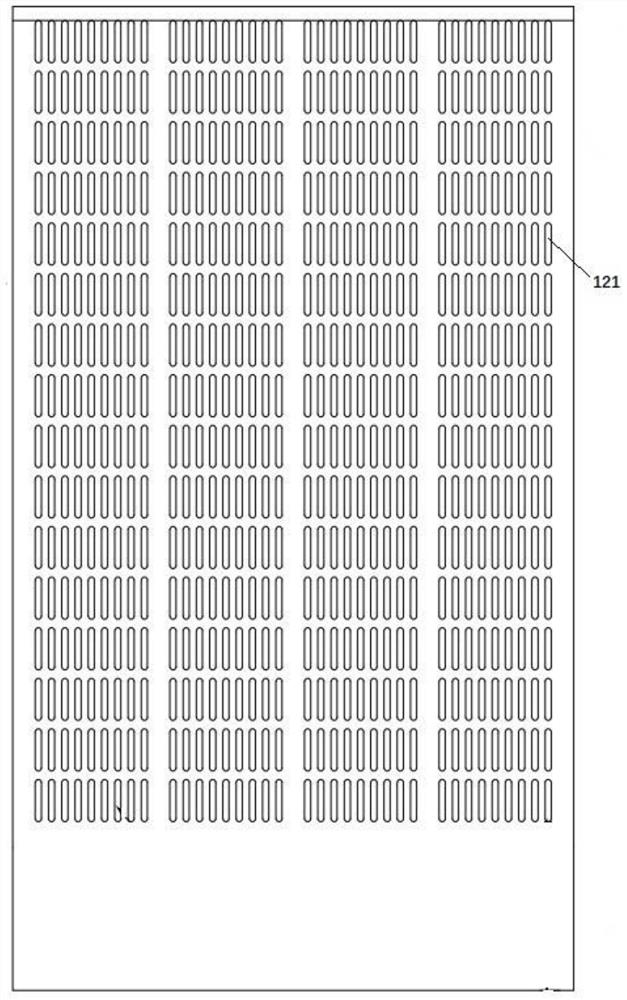

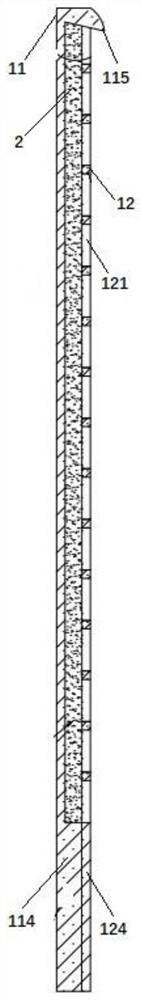

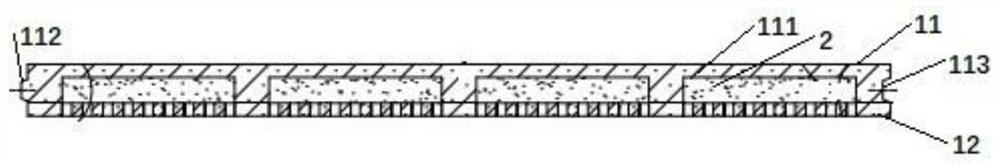

[0046] Such as Figure 1A , Figure 1B , Figure 1C Shown is the schematic diagram of the first embodiment of the sound barrier plate in the integrated upright non-metallic sound barrier system of the present invention, which includes the sound barrier plate and the sound absorption module 2, and the bottom of the sound barrier plate is arranged on the base; the sound barrier The board is composed of a backboard 11 and a panel 12, and several sound-absorbing modules 2 are arranged between the backboard 11 and the panel 12. The top of the backboard 11 is provided with a rainwater drip line 115, the bottom is a backboard base connection area 114, and the left and right sides are respectively provided with matching tenons 112 and mortises 113, and the sound-absorbing module 2 is embedded and installed on the backboard 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com