Rectangular plunger of radial plunger pump

A radial column and rectangular technology, applied in the field of hydraulic components, can solve problems such as low efficiency and poor adaptability of axial piston pumps, and achieve the effect of increasing displacement, increasing speed, and realizing rotational lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

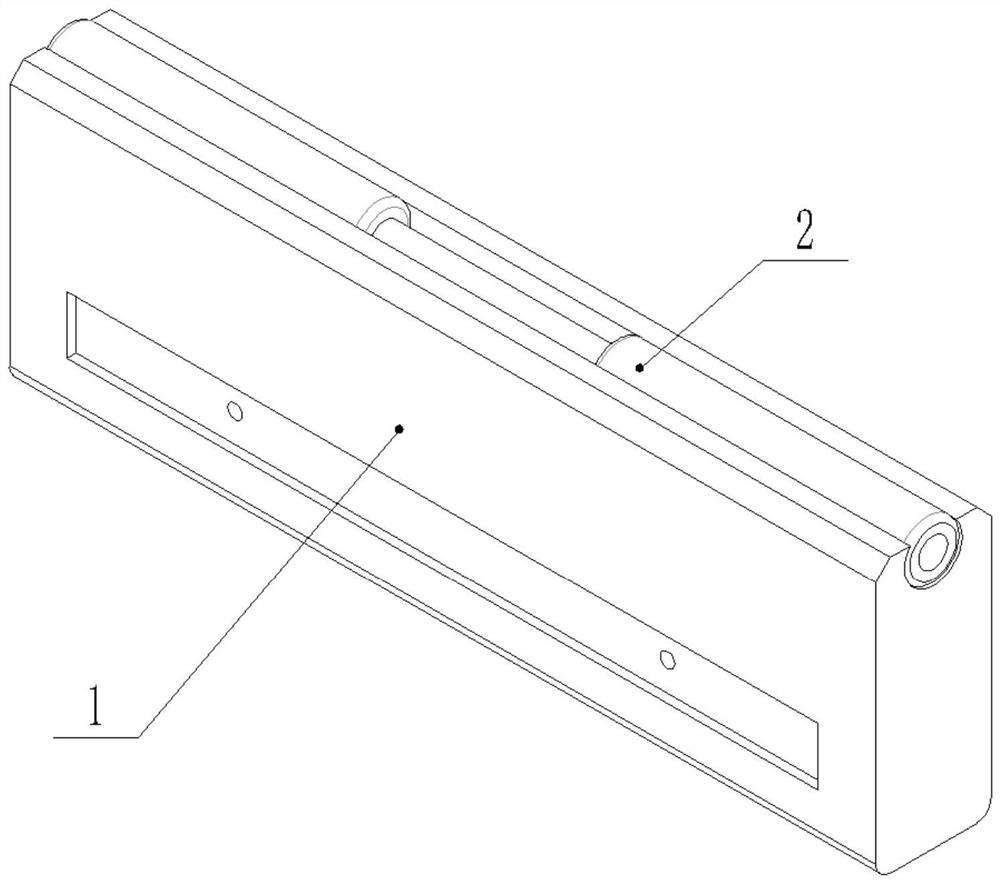

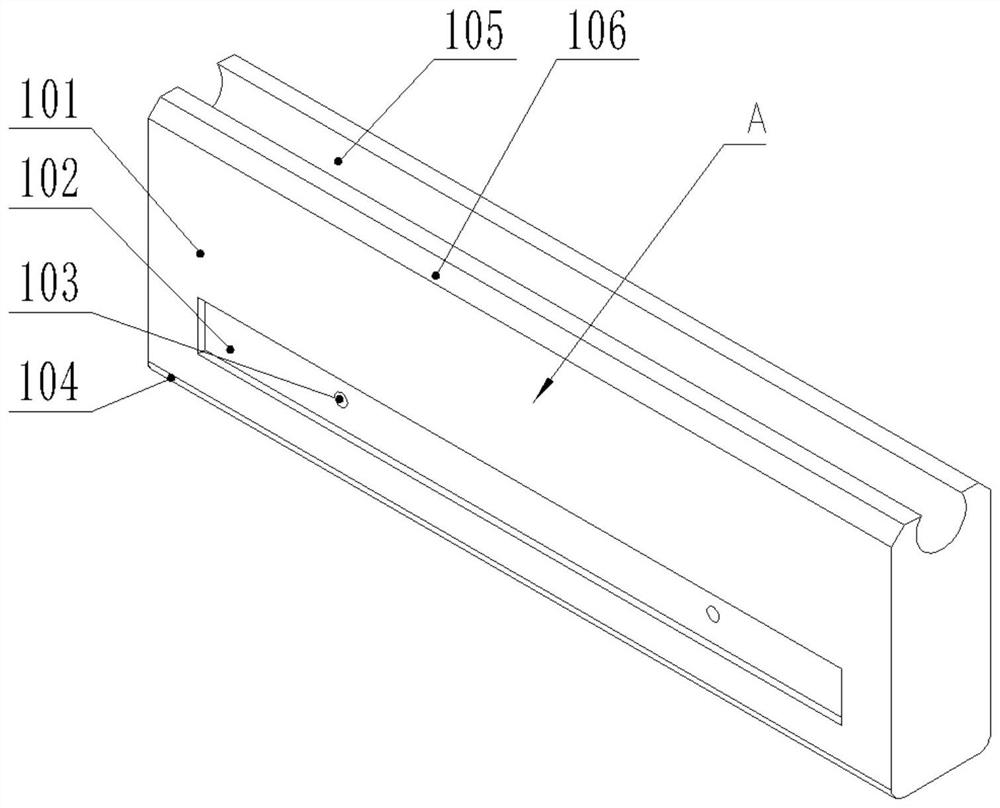

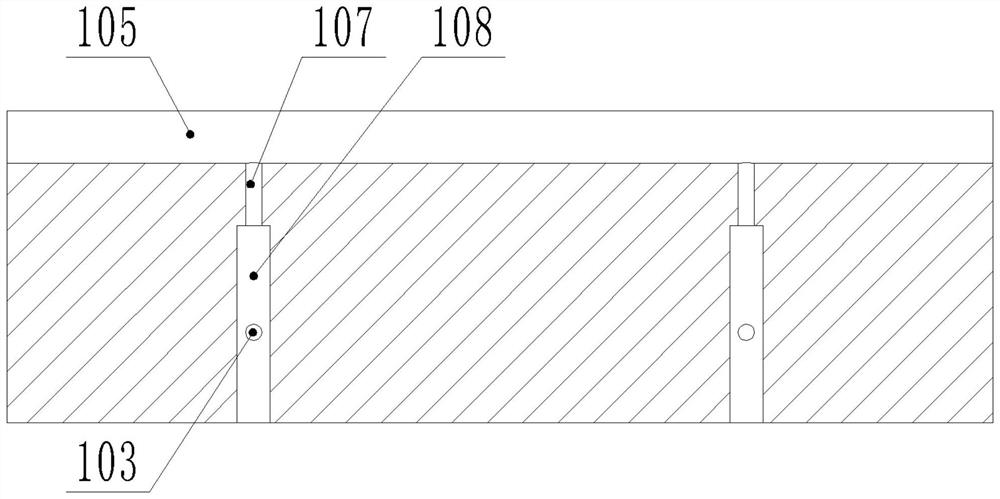

[0017] The present invention is achieved through the following technical solutions: a rectangular plunger is composed of a rectangular plunger body 1 and a roller 2, the roller 2 is embedded on the rectangular plunger body 1, and the rectangular plunger body 1 is formed by a rectangular base 101, the lower part of the front and rear end surfaces of the rectangular base 101 is provided with two symmetrical oil pools 102, one side of the oil pool 102 is processed with a damping hole 103 communicating with the other side of the oil pool 102, and the upper part of the rectangular base 101 is provided with along The rotation groove 105 that runs through the left and right directions, the inside of the rectangular base 101 is provided with the short hole 107 and the long hole 108 that are penetrated from the rotation groove 105 to the lower end surface of the rectangular base 101 in turn, the damping hole 103 communicates with the long hole 108, and the roller 2 is formed by The long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com