A Microstructured Optical Fiber Broadband Polarization Filter with Tunable Filtering Direction

A technology of micro-structure optical fiber and polarization filter, which is applied in the field of optical fiber communication, can solve the problems of non-adjustable polarization filtering direction and inability to satisfy the adjustment of polarization direction, etc., and achieves the advantages of increased resonance peak, simple structure, and high orthogonal polarization loss ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

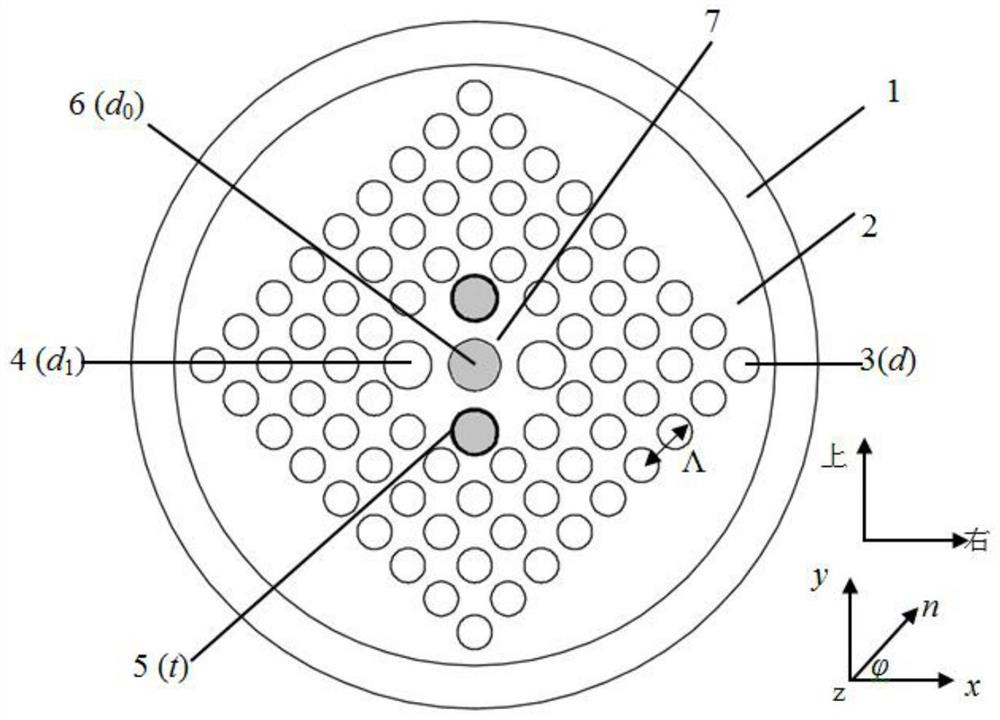

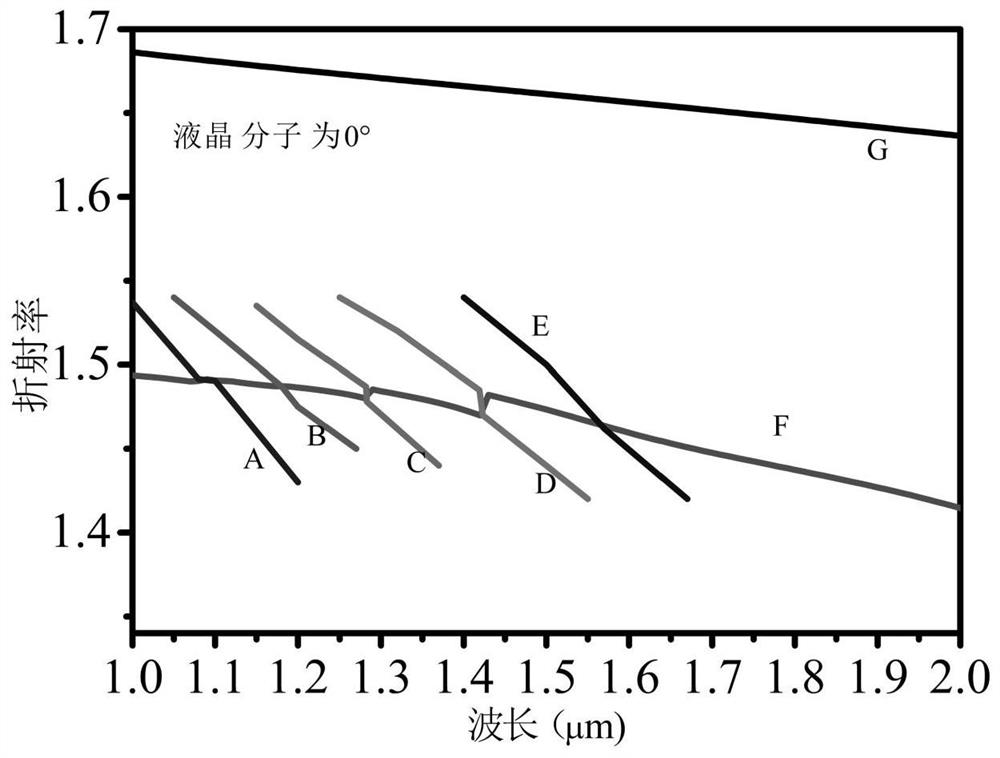

[0035] In the first embodiment, if figure 1 As shown, the two enlarged holes 4 that are symmetrical along the diagonal line are all metal-coated to form two coating holes 5, and the two coating holes 5 are filled with nematic liquid crystal E7, and the large hole toward the center of the fiber core Apply an external electric field to the nematic liquid crystals in 6 and two coating holes 5, and change the long axis direction n of the nematic liquid crystal molecules by adjusting the voltage of the applied electric field to realize the tuning of the filtering direction. The liquid crystal filling in the large hole 6 in the center of the fiber core can increase the asymmetry on the one hand, and more importantly, can realize the tuning of the filtering direction through the modulation of the external electric field.

[0036] In the present invention, due to filling the nematic liquid crystal E7 in the large hole 6 in the core area of the fiber core, the arrangement of the nema...

Embodiment 2

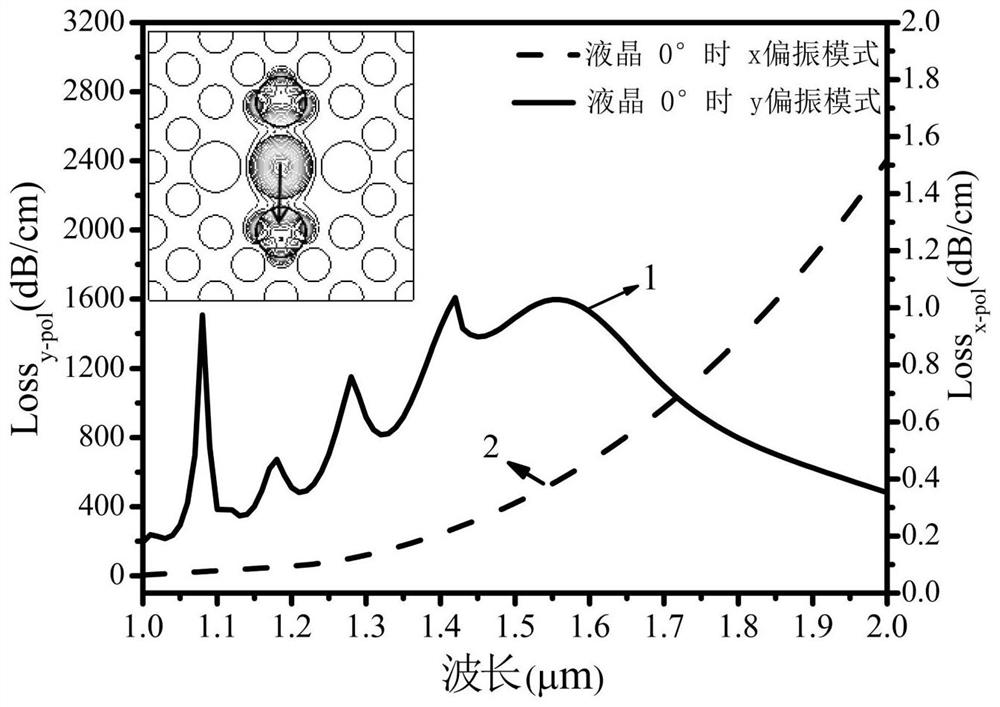

[0045] In the second embodiment, if Figure 6 As shown, the two enlarged holes that are symmetrical along the diagonal are all metal-coated to form two coating holes. Liquid crystal, only the large hole in the center of the optical fiber is filled with liquid crystal; Figure 7 As shown, the curves 1 and 2 are the rotation angles of the director direction n of the liquid crystal molecules respectively When 0° is the loss in the two orthogonal polarization directions of the fiber x and y. Depend on Figure 7 It can be seen that the curve 1 shows that although there is only one resonant coupling point between the core mode of the y-polarization direction between 1 μm and 2 μm, due to the incomplete coupling of the core mode and the surface plasmon mode in the y-polarization direction in the broadband band, the y-polarization The directional core mode loss is greater than 340dB / cm in the band 1μm and 2μm. Curve 2 shows the transmission loss of the core mode of the x-polarize...

Embodiment 3

[0047] The structure of the third embodiment is the same as that of the first embodiment, the difference is as Figure 8 As shown, in the inner cladding region, one of the four enlarged holes is arbitrarily selected for metal coating, and the coating hole is not filled with liquid crystals, and only the large hole in the center of the optical fiber is filled with liquid crystals. Such as Figure 9 As shown, the curves 1 and 2 are the rotation angles of the director direction n of the liquid crystal molecules respectively When 0° is the loss in the two orthogonal polarization directions of the fiber x and y. Depend on Figure 9 It can be seen that the curve 1 shows that the loss of the core mode in the y-polarization direction at the wavelength bands 1.05 μm and 2 μm is greater than 262 dB / cm. Curve 2 shows that the core mode loss in the x-polarization direction is less than 0.8dB / cm in the band between 1.05μm and 2μm. Compared with Embodiment 2, Embodiment 3 reduces a sym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com