High-precision controller for ultra-low-speed control moment gyroscope frame servo system

A technology for controlling torque gyroscopes and servo systems, applied in general control systems, control/regulation systems, adaptive control, etc., can solve the problems of reducing angular rate control accuracy and insufficient speed detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

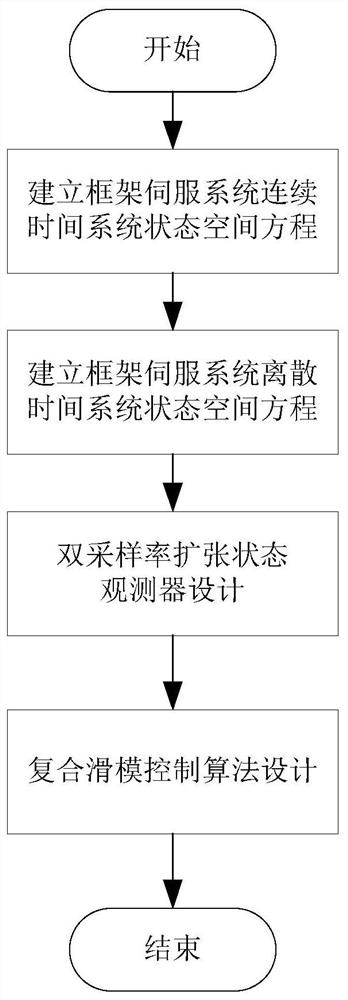

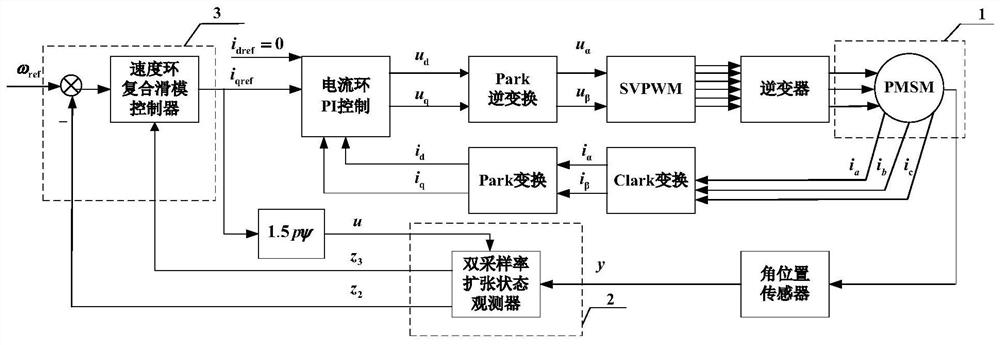

[0055] Specific implementation mode one: see figure 2 Describe this embodiment, a high-precision controller for an ultra-low-speed control moment gyro frame servo system described in this method, including a frame servo system mathematical model part 1, a double sampling rate expanded state observer part 2, and a composite sliding mode control algorithm part 3. The specific implementation steps are as follows:

[0056] Step 1: Build a mathematical model of the frame servo system:

[0057] According to the sampling period of the speed loop controller, the continuous-time system state-space equation of the frame servo system is discretized to obtain the discrete-time system state-space equation of the frame servo system, and the mathematical model part 1 of the frame servo system can be obtained.

[0058] (1) Establish the continuous time system state equation of the frame servo system as:

[0059]

[0060] where θ is the frame motor angular position, ω is the frame motor ...

specific Embodiment approach 2

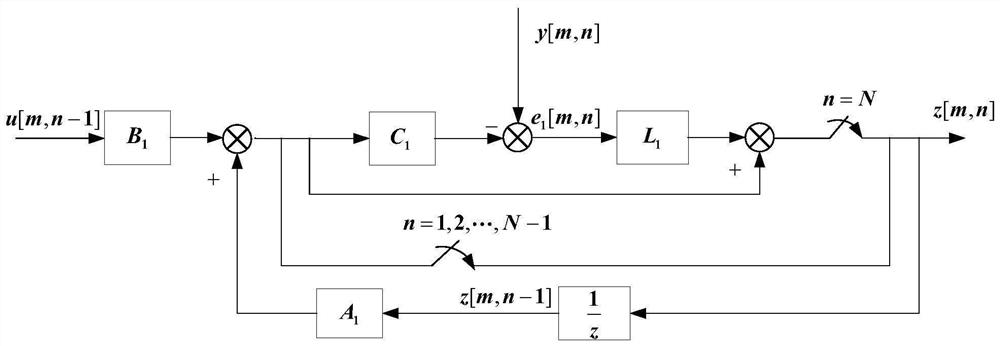

[0077] Embodiment 2: This embodiment is a further limitation of the high-precision controller of the ultra-low-speed control torque gyro frame servo system described in Embodiment 1. See image 3 Illustrate this embodiment, the specific design method of described double sampling rate expansion state observer part 2 is as follows:

[0078] The speed loop controller sampling time t=[m,n] between the position sensor data change time, where n=1,2,...,N-1, the position sensor cannot detect the angular position change of the frame motor, according to The state-space equations for a discrete-time system of frame motors estimate system states such as angular velocity and "lumped disturbances":

[0079]

[0080] Among them, the state variable estimation matrix z=[z 1 z 2 z 3 ] T the z 1 ,z 2 ,z 3 are used to estimate x 1 、x 2 、x 3 , […] T represents the transpose of the matrix […], z 1 [m,n] indicates that the sampling time of the speed loop controller is t=[m,n] when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com