A high-precision controller for ultra-low speed control moment gyro frame servo system

A servo system and controller technology, applied in general control systems, control/regulation systems, adaptive control, etc., can solve the problems of reducing angular rate control accuracy and insufficient speed detection accuracy, so as to enhance the ability of disturbance suppression and realize angular control. High-precision rate control and the effect of suppressing residual disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

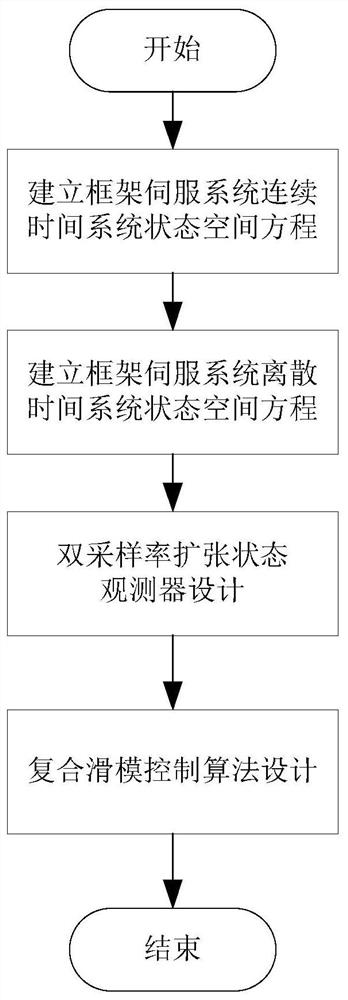

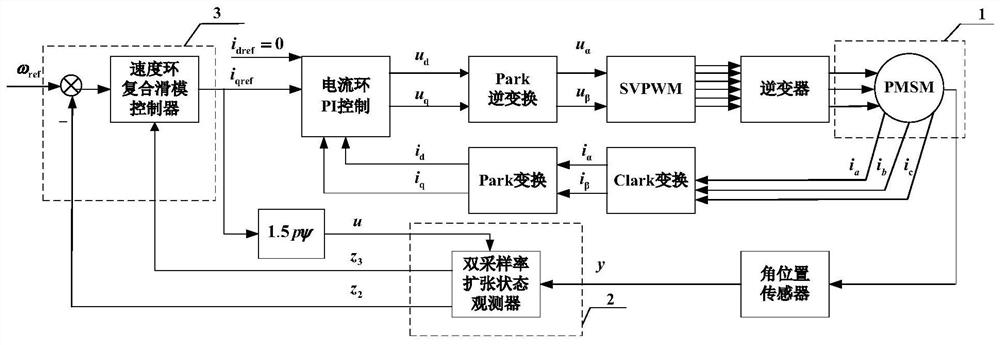

[0055] Specific implementation mode 1: see figure 2 This embodiment is described. A high-precision controller of an ultra-low-speed control torque gyro frame servo system described in this embodiment includes a frame servo system mathematical model part 1, a double sampling rate expansion state observer part 2, and a composite sliding mode control algorithm part. 3, its specific implementation steps are as follows:

[0056] Step 1: Build the frame servo system mathematical model:

[0057] According to the sampling period of the speed loop controller, the continuous time system state space equation of the frame servo system is discretized, and the discrete time system state space equation of the frame servo system is obtained, and the frame servo system mathematical model part 1 can be obtained.

[0058] (1) The state equation of the continuous time system to establish the frame servo system is:

[0059]

[0060] where θ is the frame motor angular position, ω is the frame...

specific Embodiment approach 2

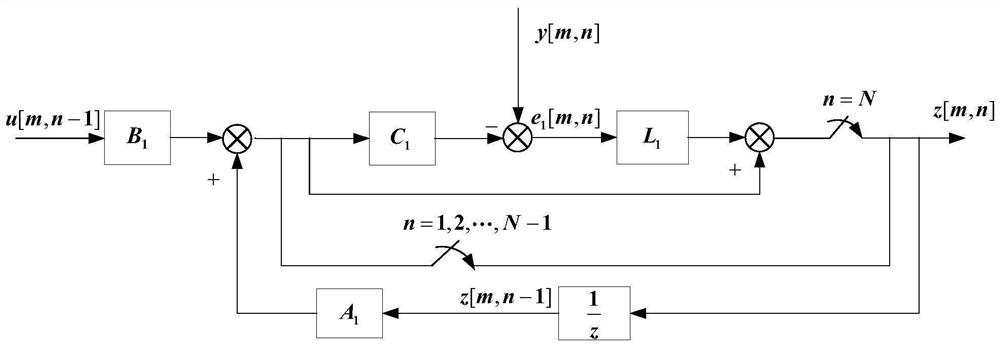

[0077] Embodiment 2: This embodiment is a further limitation of the high-precision controller of the ultra-low speed control torque gyro frame servo system described in Embodiment 1, see image 3 Illustrating this embodiment, the specific design method of the double sampling rate extended state observer part 2 is as follows:

[0078] At the sampling time t=[m,n] of the speed loop controller between the changing times of the position sensor data, where n=1,2,...,N-1, the position sensor cannot detect the angular position change of the frame motor, according to The discrete-time system state-space equations for frame motors estimate system states such as angular velocity and "lumped disturbances":

[0079]

[0080] Among them, the state variable estimation matrix z=[z 1 z 2 z 3 ] T z 1 ,z 2 ,z 3 are used to estimate x 1 , x 2 , x 3 , […] T represents the transpose of the matrix […], z 1 [m,n] means z when the sampling time of the speed loop controller is t=[m,n]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com