High-precision control method of control torque gyro frame system based on harmonic reducer

A technology for controlling torque gyroscopes and harmonic reducers, applied in general control systems, control/regulation systems, adaptive control, etc., can solve the problem of low output angular rate accuracy, alleviate chattering problems, and reduce estimation burden , Improve the effect of control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The technical solutions in the embodiments of the present invention will be described below with reference to the drawings in the embodiments of the present invention.

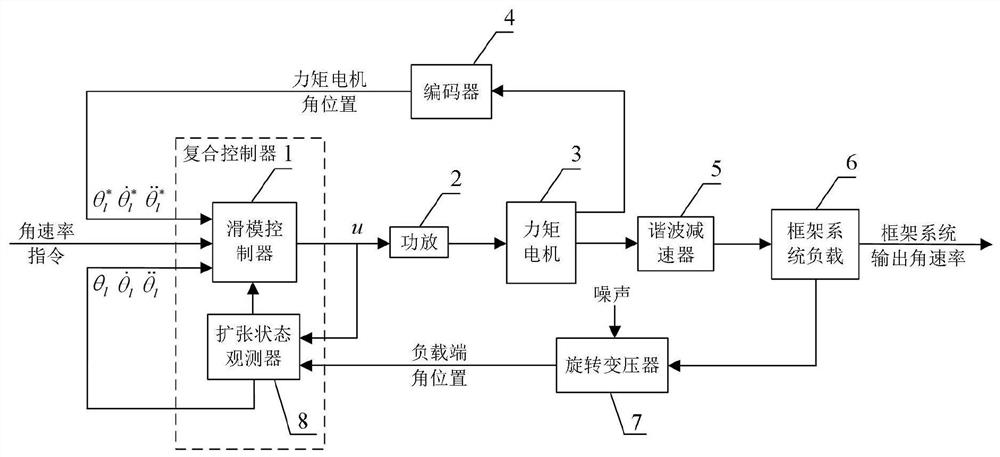

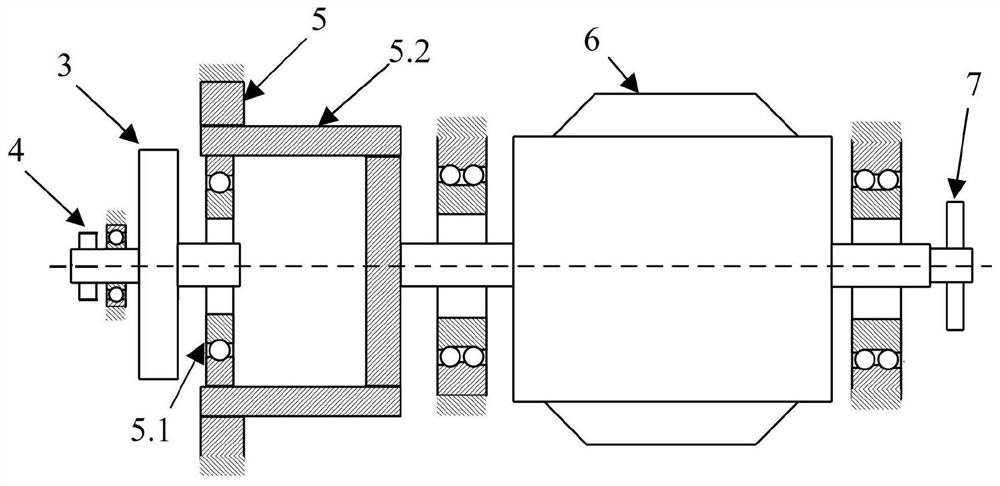

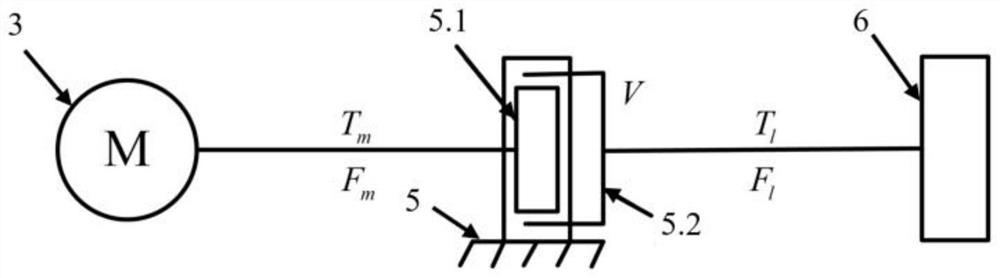

[0059] Such as figure 1 As shown, a control torque gyro frame system based on harmonic reducer, including: sliding mode controller 1, power amplifier 2, torque motor 3, encoder 4, harmonic reducer 5, frame system load 6, resolver 7 , Expanded state observer 8: wherein, the sliding mode controller 1 suppresses and compensates the disturbance in the system in real time through the control input and then generates a control signal, outputs the actual control current through the power amplifier 2 to drive the torque motor 3, and is fixedly connected to the torque motor 3 The encoder 4 on the motor shaft is used to measure the angular position of the torque motor 3, the output end of the torque motor 3 is rigidly connected to the input end of the harmonic reducer 5 and the speed is the same, and the harmonic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com