3D printing supporting area generation method based on supporting point expansion fusion

A technology of 3D printing and expansion fusion, applied in geometric CAD, instrumentation, electrical digital data processing, etc., can solve problems such as difficulties in generating support areas, and achieve the effect of clear algorithm logic and design, good robustness, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] Taking the "F" model as an example, the embodiments of the present invention will be further described in detail in conjunction with the accompanying drawings. The following examples do not limit the present invention.

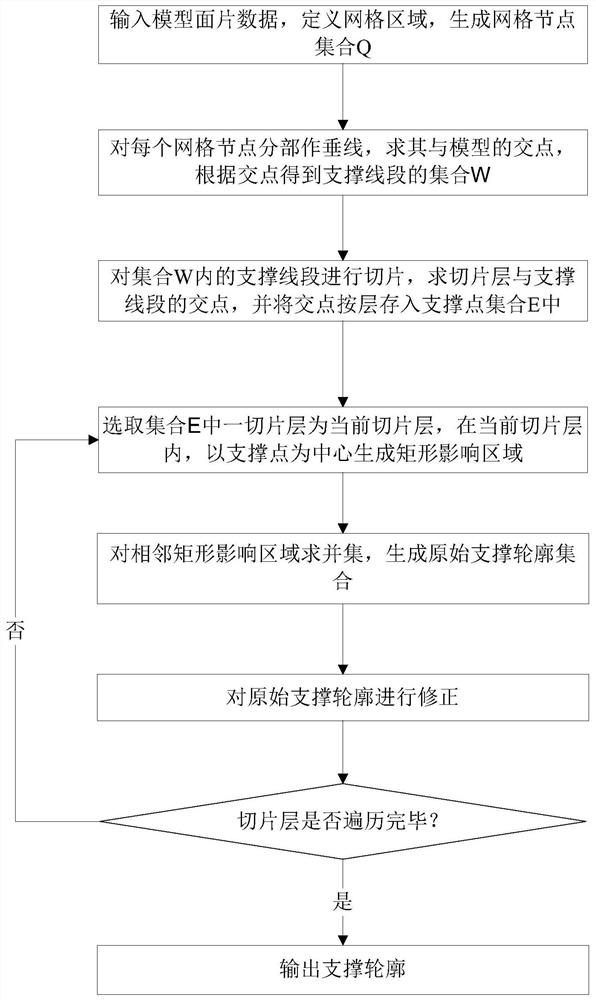

[0071] A flow chart of a 3D printing support region generation method based on support point expansion and fusion is shown in figure 1 As shown, the specific implementation steps are as follows:

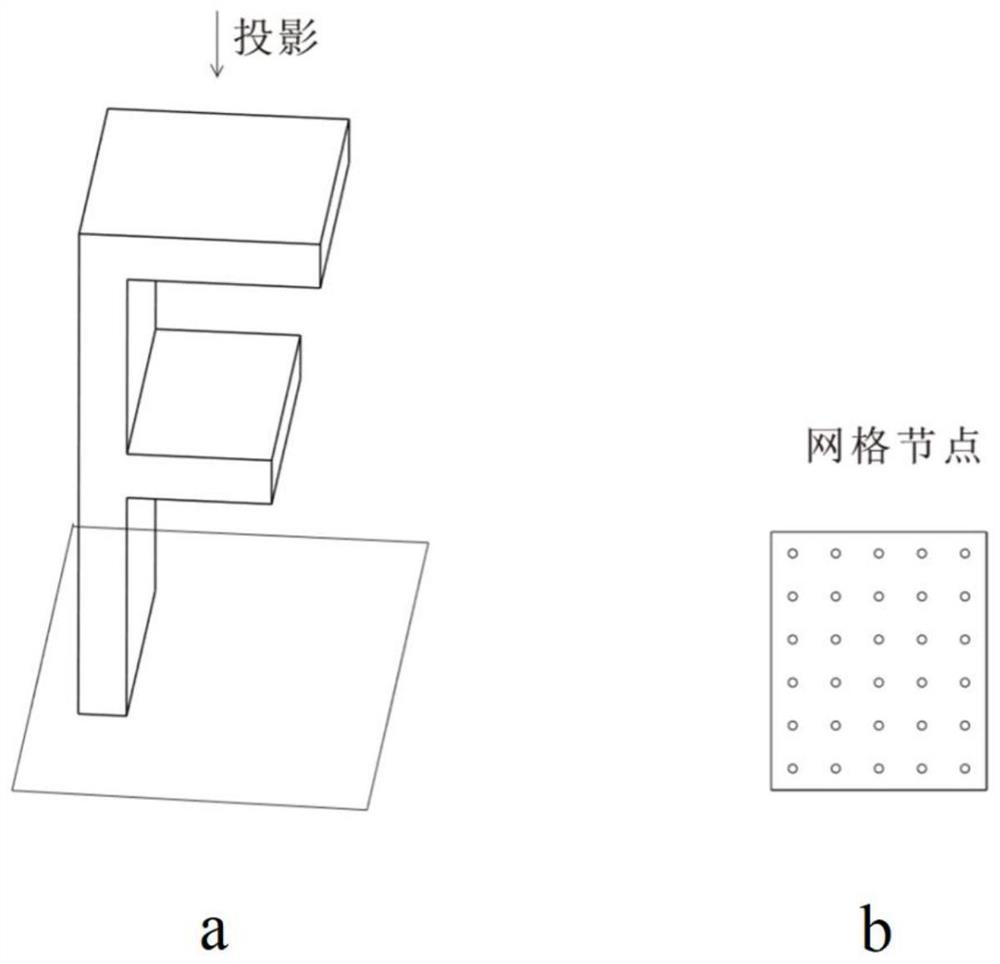

[0072] Step 101: Input the model "F" data and its surface patch data, and set the initial mesh side length L 0 and support critical angle θ 0 , a model such as figure 2 a;

[0073] Step 102: According to the model extreme value and L 0 Generate a uniform projection grid node set Q on the XY plane, the grid nodes such as figure 2 as shown in b.

[0074] Before generating the grid node set Q, first according to the model extreme value and L 0 The optimal adjustment of the grid side length is as follows:

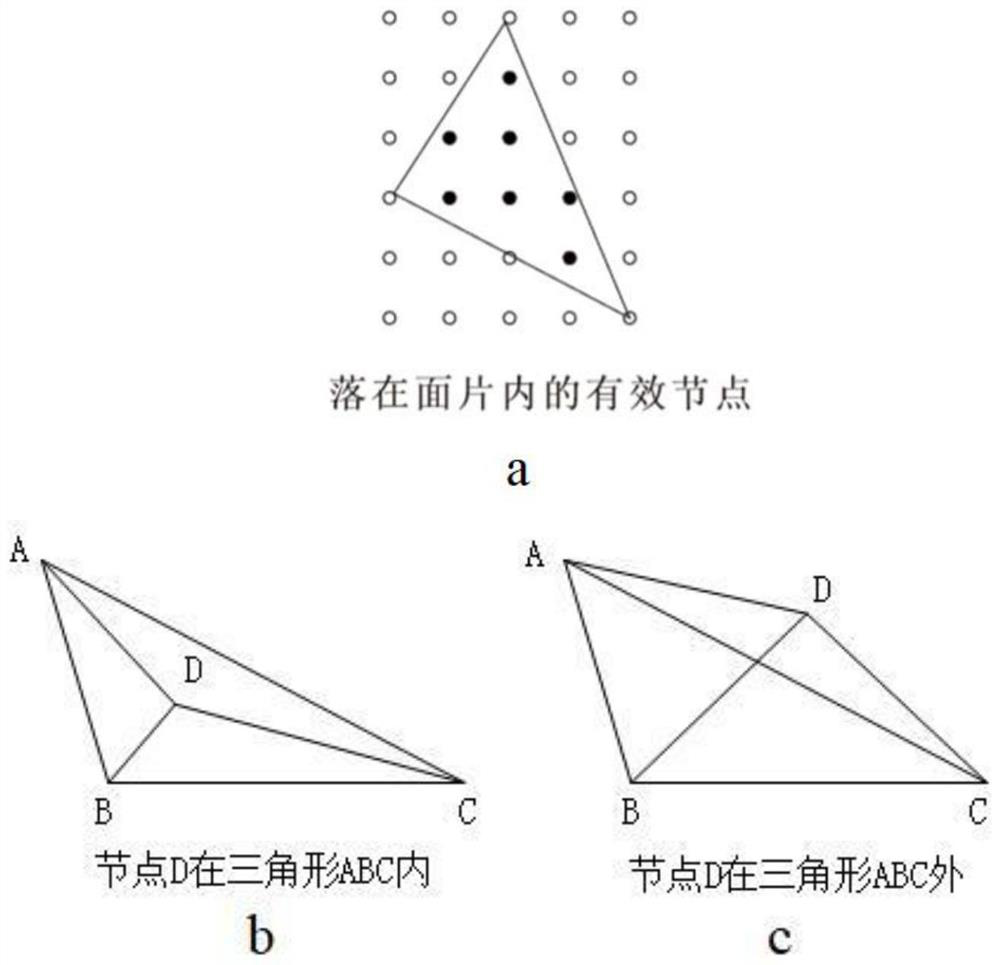

[0075] The extreme values of the model in the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap