Method for positioning shell part in horizontal machining center and machining method

A technology of positioning method and processing method, which is applied in the direction of positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of non-coincidence between the workpiece reference point and the rotary center of the worktable, long standby time, and deviation, and achieve reduction The effect of debugging scrap rate, improving efficiency, improving accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

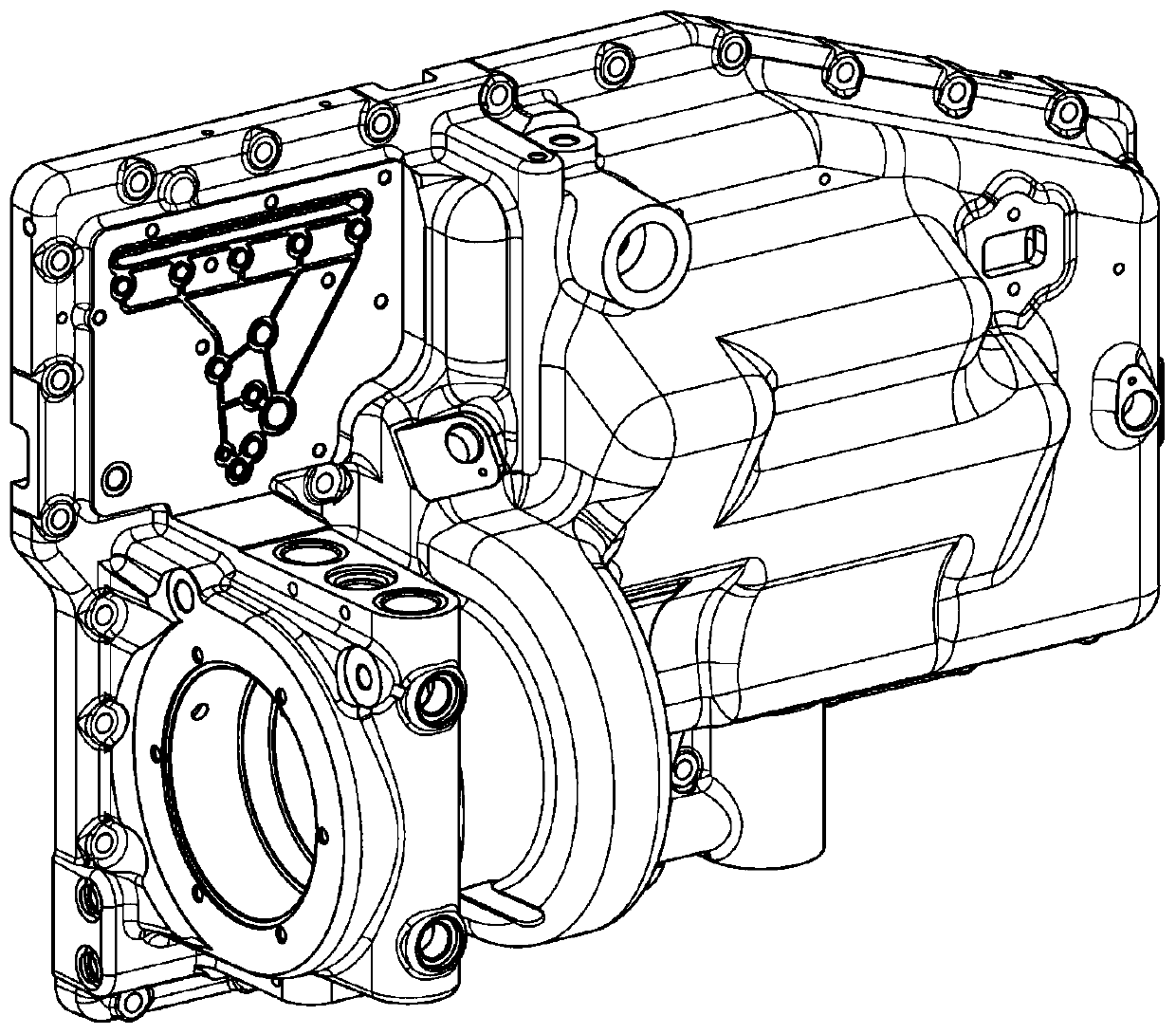

[0055] This embodiment specifically provides a positioning method taking the side cover shell as an example, which is used to determine the clamping position of the side cover shell on the machine tool workbench after the workbench is rotated, including the following steps:

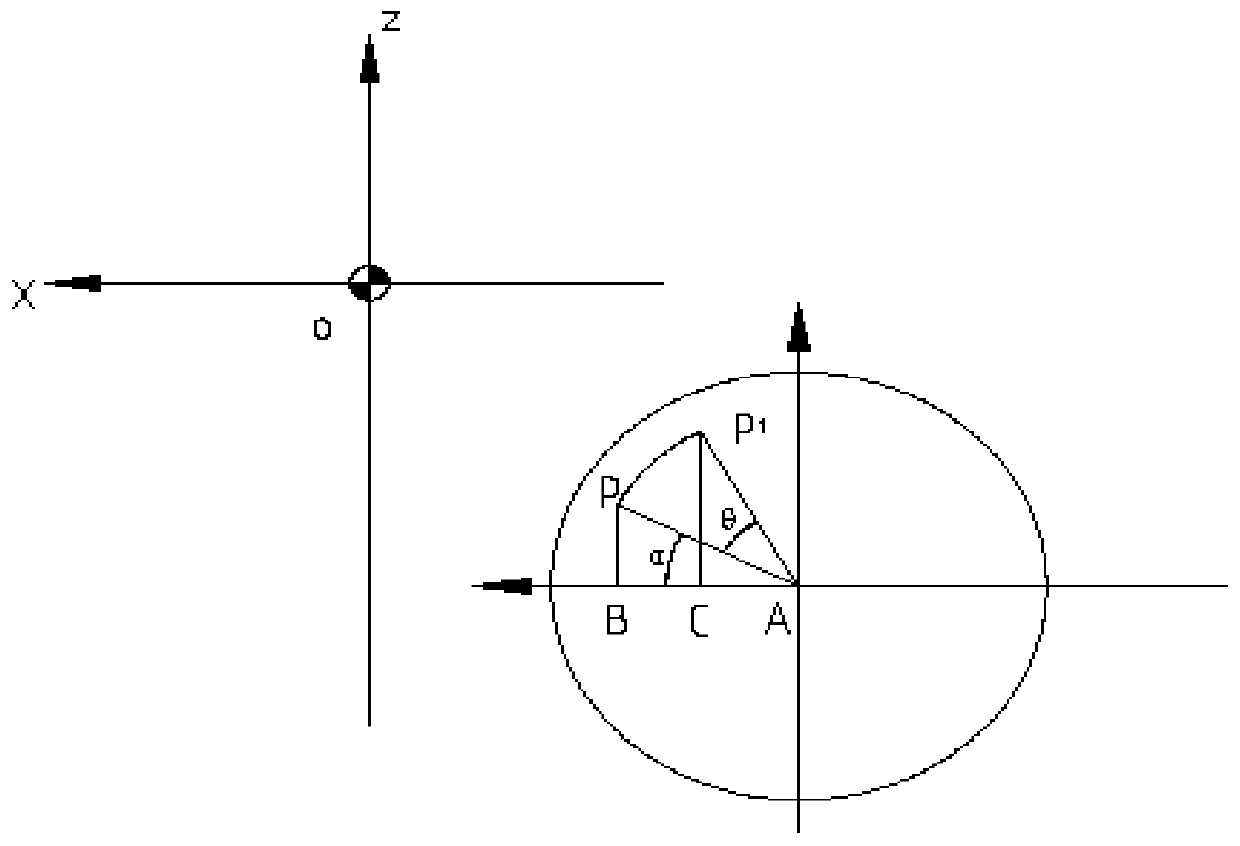

[0056] Step 1. Establish the machine tool coordinate system, and obtain the coordinates (a, b, c) of the center point A of the machine tool workbench and the coordinates (x, y, z) of the reference point P of the side cover shell in the machine tool coordinate system, The reference point P of the side cover housing is at any position on the machine tool table;

[0057] Step 2. According to the coordinates (a, b, c) of the turning center point A of the machine tool table described in step 1 and the coordinates (x, y, z) of the housing part reference point P, obtain the side cover housing reference point The distance between P and the turning center point A of the machine tool table and the angle ∝ between the...

Embodiment 2

[0080] This embodiment provides a processing method for shell parts on a horizontal machining center, including adopting the positioning method of the shell parts on the horizontal machining center of the present invention, and determining the position of the shell parts on the machine tool workbench after the workbench rotates. The clamping position, and then the processing method of production and processing, this method fixes the shell parts at any position on the machine tool table, and realizes the automatic offset of the coordinate origin during multi-directional processing.

[0081] This processing method specifically comprises the following steps:

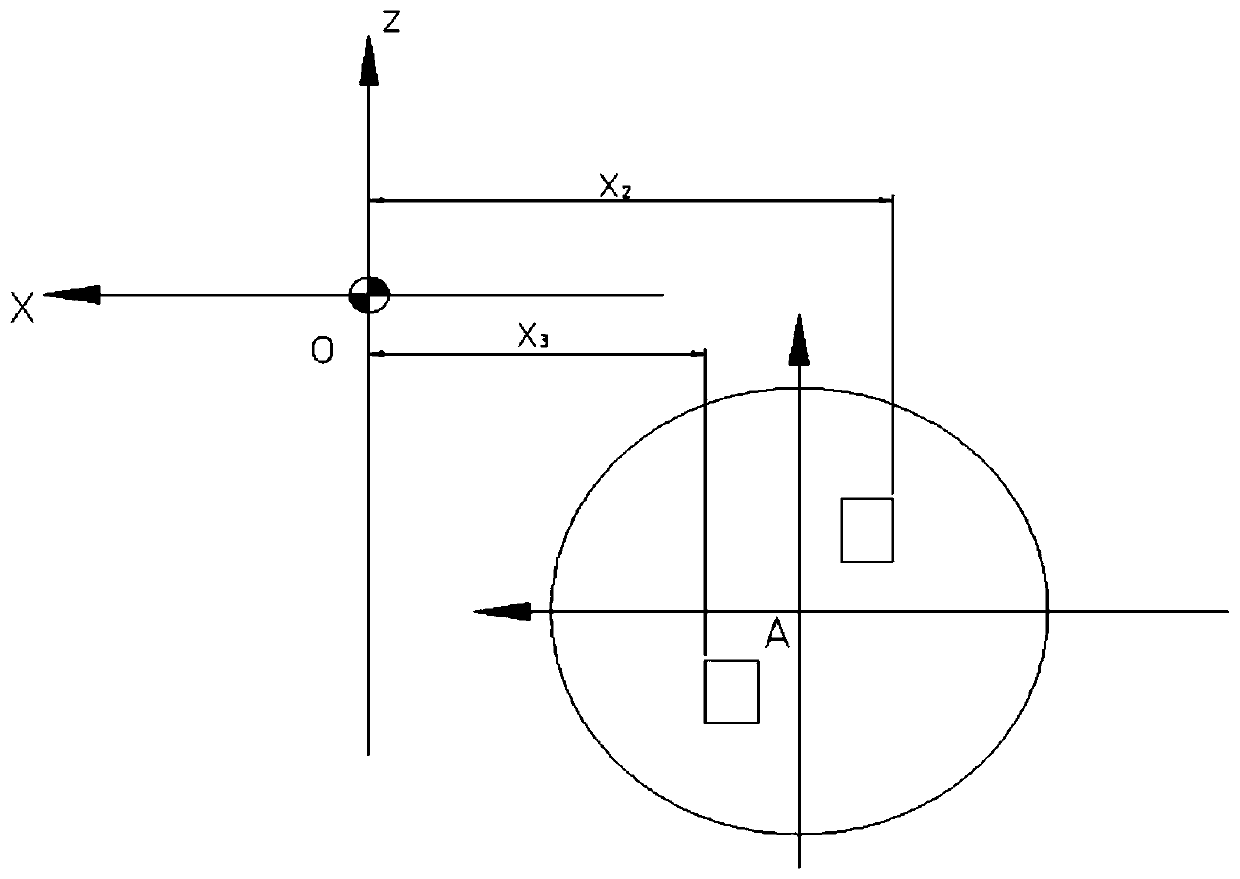

[0082] Step 1. Fix the shell parts at any position on the machine tool workbench, determine the reference point P of the shell parts in the position of the machine tool coordinate system; convert the origin of the G54 coordinate system according to the size of the drawing, and input the zero offset value of the origin of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com