Full-cycle suspension and torque compensation control method of bearingless switched reluctance motor

A technology of switched reluctance motor and control method, which is applied to AC motor control, control system, electrical components, etc., can solve the problems of frequent switching times of power switch tubes, large number of power converters, and increased control costs, etc. Control costs, reduce the number of use, and control the effect of simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

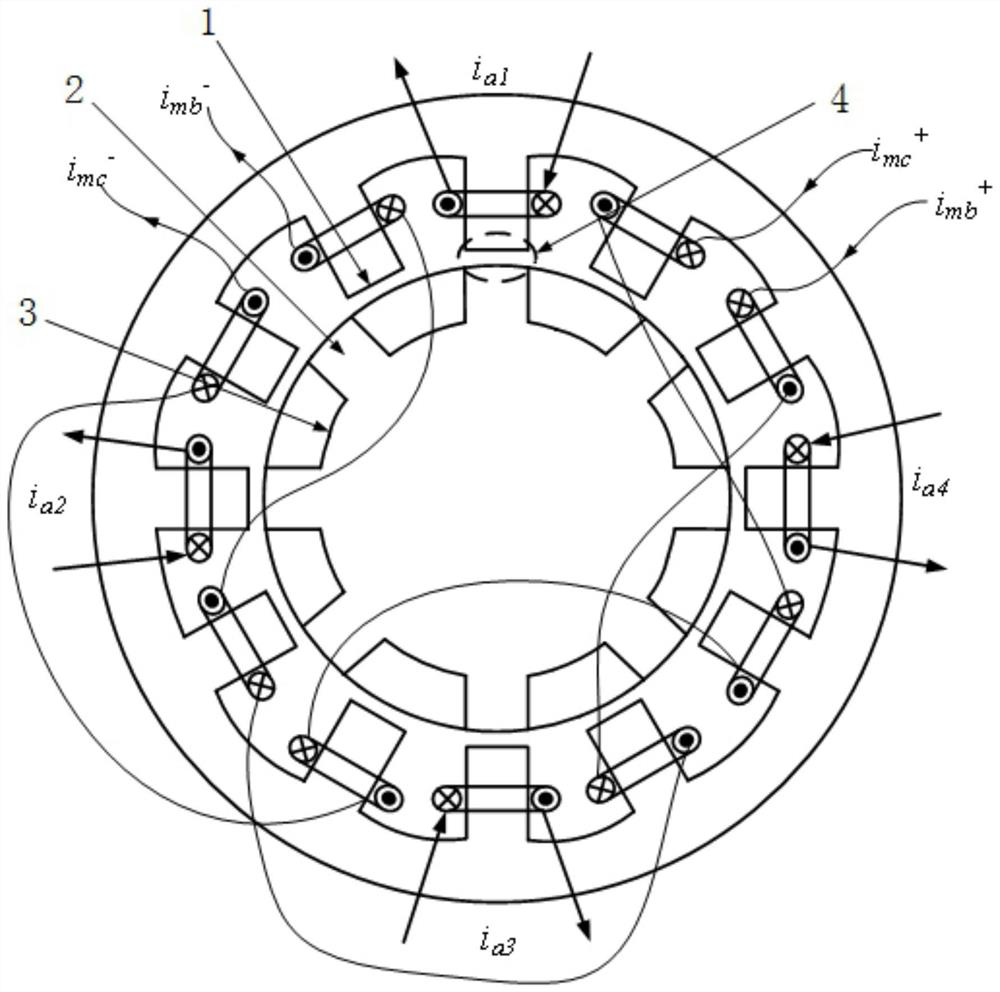

[0053] The control method provided by the embodiment of the present invention is suitable for a bearingless switched reluctance motor, as shown in FIG. 1 , which is a schematic structural diagram of a three-phase 12 / 8-pole composite rotor single-winding bearingless switched reluctance motor. 1 is the stator, 2 is the salient pole rotor, 3 is the cylindrical rotor, and 4 is the air gap. Stator 1 is a salient pole structure, the number of stator teeth is 12, and there is only one set of windings on each stator tooth; A-phase winding consists of 4 coils separated by 90°, and each winding is independently controlled; B-phase winding consists of 4 The 90° coils are formed in series; the remaining 4 X coils are connected in series to form the C-phase winding; the three-phase windings of A, B, and C are separated by 30° in space; the rotor is composed of a cylindrical rotor 3 and a salient-pole rotor 2, and the cylindrical rotor 3 It is a cylindrical structure, the salient pole rotor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com