Small solid-liquid separation device suitable for well site and solid-liquid separation method

A solid-liquid separation, small-scale technology, applied in the field of oil drilling, can solve the problems of inability to adjust, inconvenient transportation and installation, fixed screen angle, etc., to reduce the accumulation of fine particles, maintain long-term normal use, and improve the screening effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

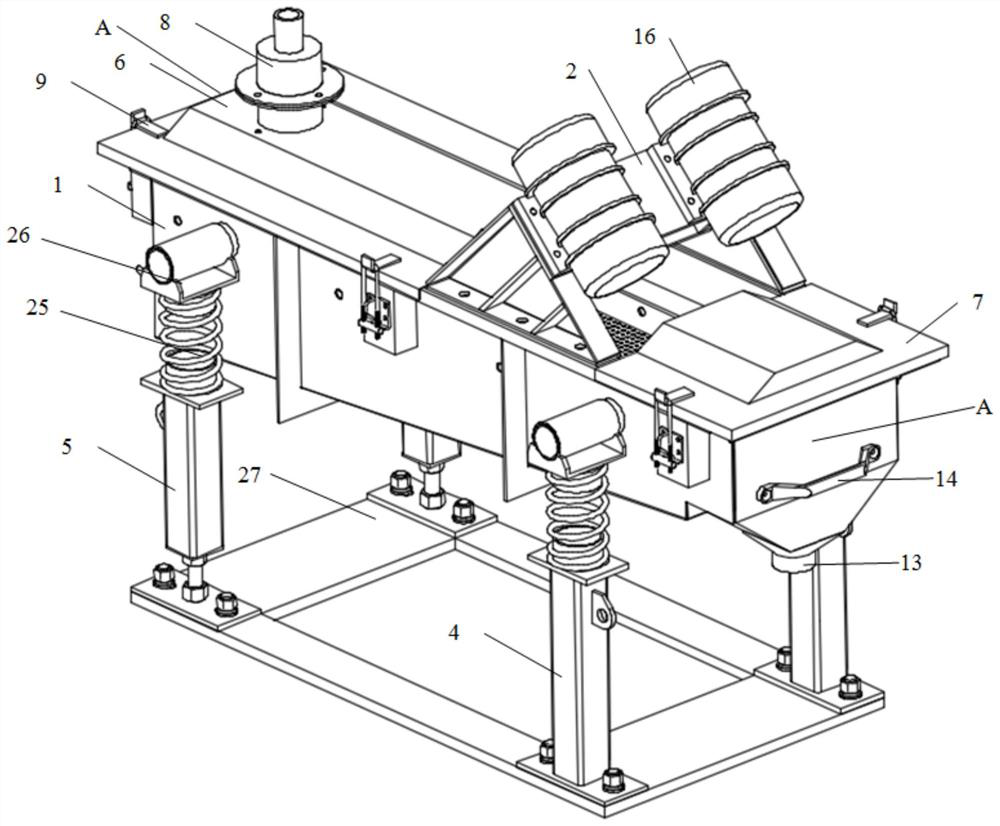

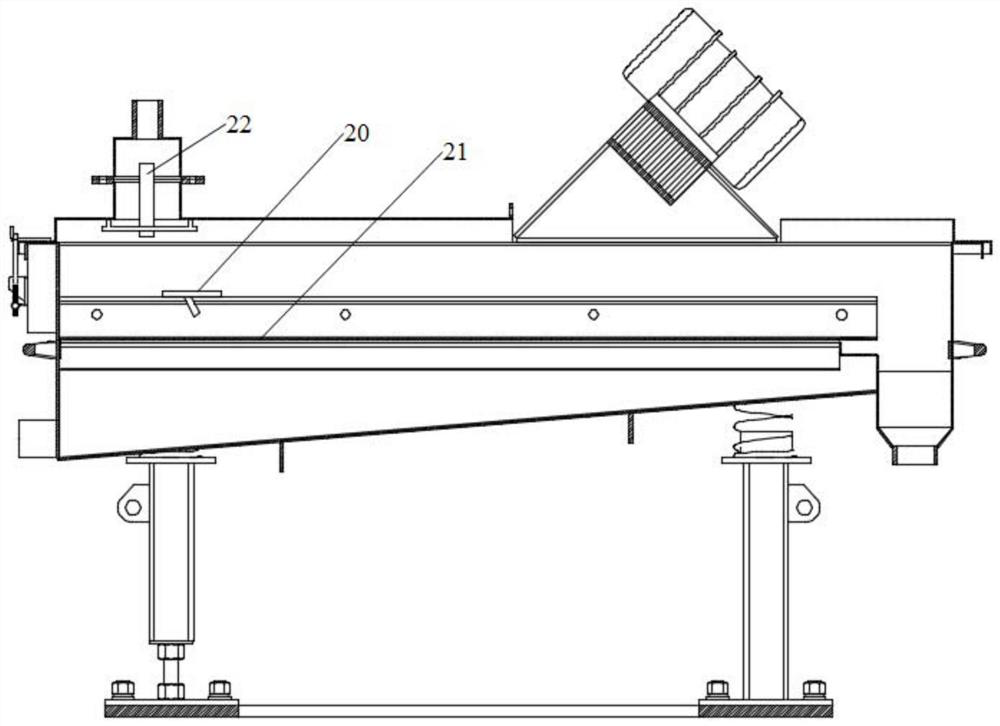

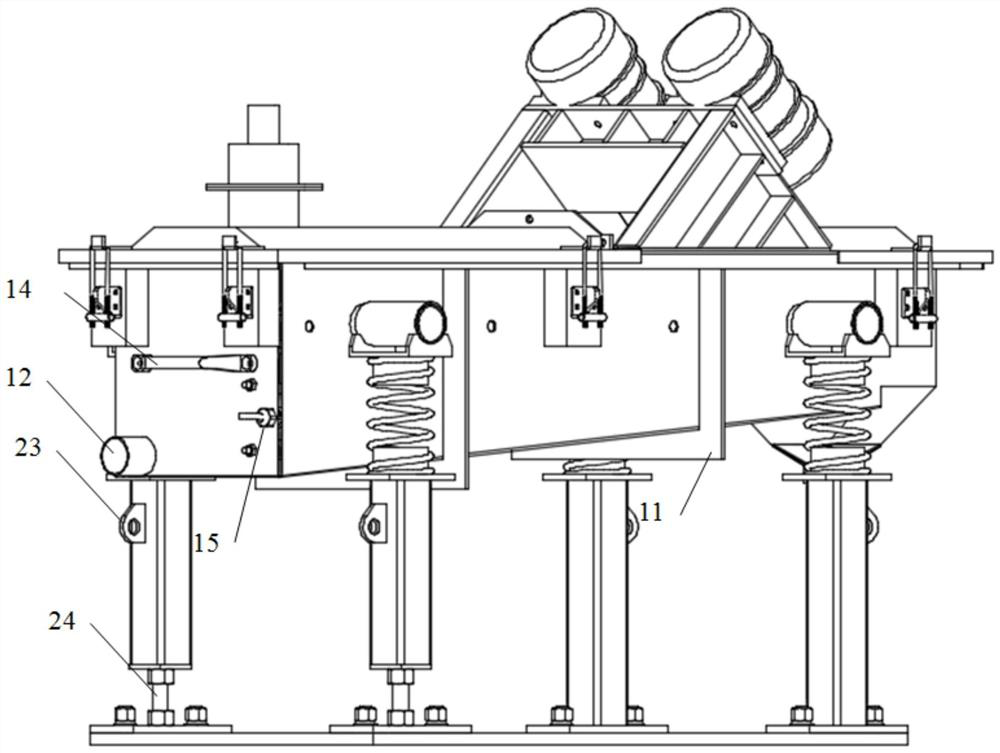

[0024] Example 1, such as Figure 1-4 As shown, this embodiment discloses a small solid-liquid separation device suitable for use in well sites, including a trough-shaped screening box 1, a motor base 2 is installed on the screening box, and a vibration motor is installed on the motor base. 16. Install a detachable cover plate on the top of the screening box, and install a feed port 8 on the cover plate. The feed port is located at the rear end of the rear cover plate described below. The structural parts can be selected according to the diameter of the feed pipe Make a replacement. Install the screen 3 horizontally in the screening box, leave a gap between the front end of the screen and the side wall of the screening box, the bottom of the screening box is inclined from front to back, and at the bottom of the screening box The front end is opposite to the above-mentioned gap to set up a closing type discharge port 13, and a liquid discharge port 12 is arranged at the end of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap