Waste paper crushing device for environmental protection

A pulverizing device and waste paper technology, applied in punching machines, presses, grain processing, etc., can solve problems such as inability to meet demand, and achieve the effect of improving space utilization, compressing volume, and facilitating transportation and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

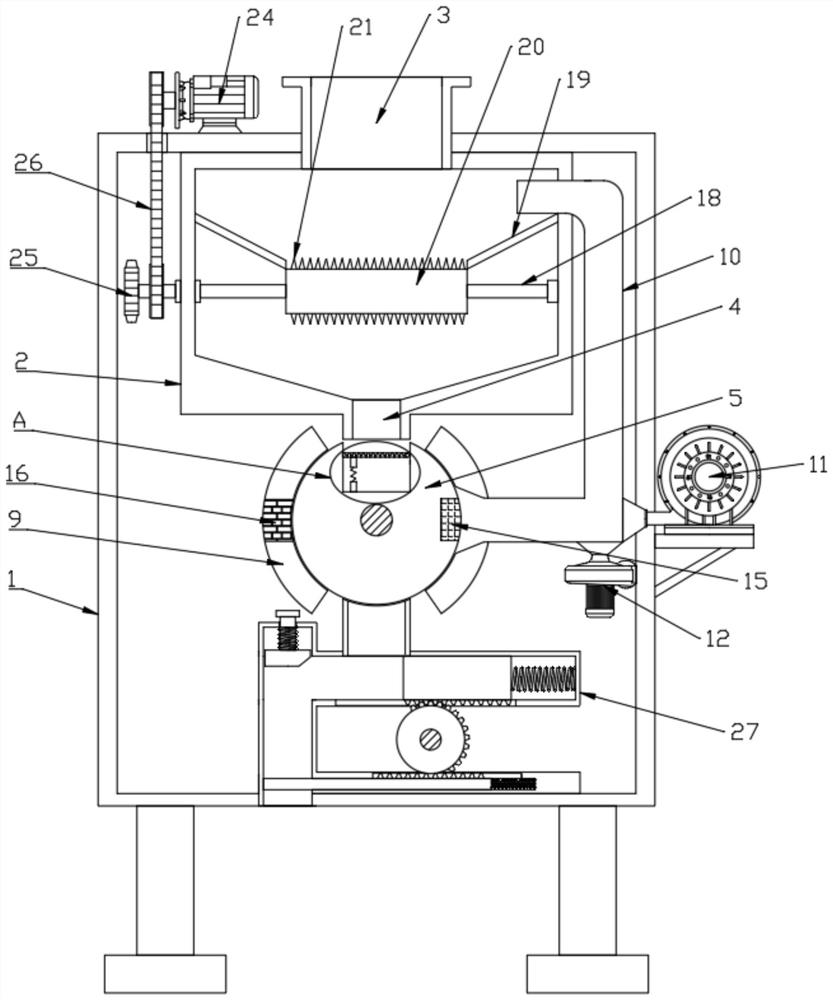

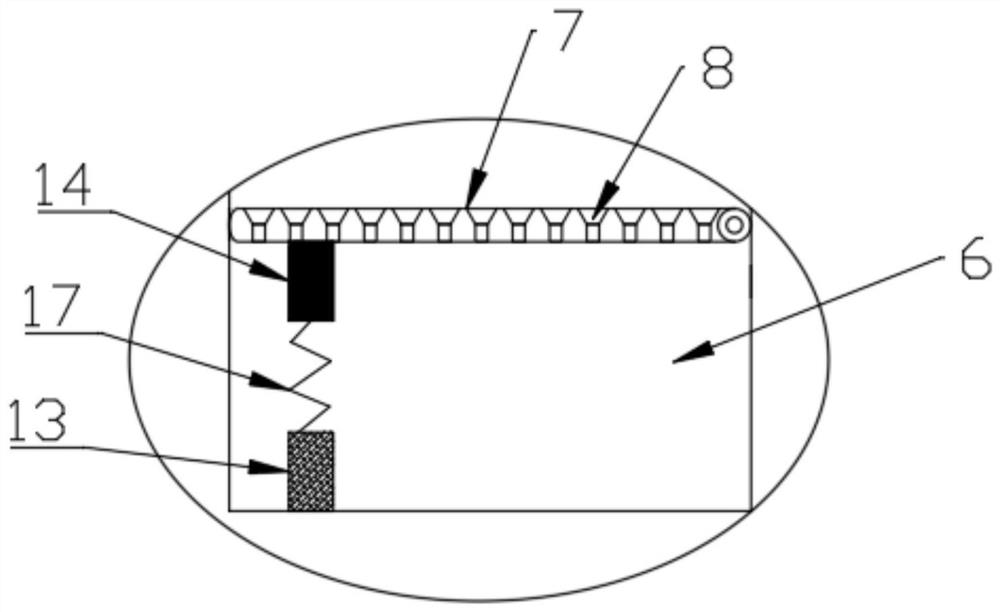

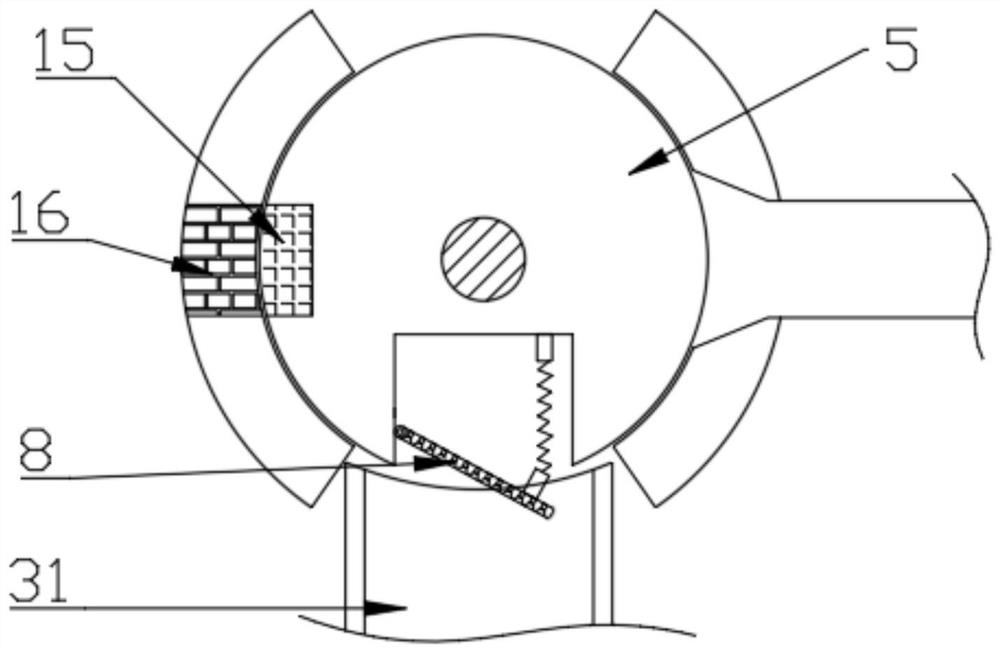

[0026] see Figure 1-5 , a waste paper shredding device for environmental protection, comprising a shell 1 and an inner tank 2, the inner tank 2 is arranged inside the outer shell 1, and the inner tank 2 is fixedly connected to the top surface of the outer shell 1, and the top surface of the inner tank 2 is opened There is a feed port 3 communicating with the shell 1, a discharge port 4 is provided on the bottom surface of the liner 2, and the liner 2 is provided with a crushing mechanism, and a discharge mechanism is arranged below the liner 2 in the shell 1, and the An extruding mechanism is arranged below the discharge mechanism, and the discharge mechanism includes a roller 5 that rotates below the discharge port 4 and a driving element that drives the roller 5 to rotate. The outer surface of the roller 5 is provided with a groove 6, so that A partition 7 is provided in the groove 6, and a filter hole 8 is provided on the partition 7, and one end of the partition 7 is rota...

Embodiment 2

[0031] This embodiment describes the extrusion mechanism in detail on the basis of Embodiment 1, specifically:

[0032] Described extruding mechanism comprises fixed frame 27, semi-gear 28 and the driving element that drives semi-gear 28 to rotate, has first channel 29 and second channel 30 in described fixed frame 27, and the top of described first channel 29 and The left side is respectively provided with a feed channel 31 and a discharge channel 32 communicating with it, and the first channel 29 and the second channel 30 are respectively slidably connected with an extruding block 33 and a baffle plate 34, and the extruding block 33 and the A second spring 35 is connected between the right side wall of the first passage 29, a third spring 36 is connected between the baffle plate 34 and the right side wall of the second passage 30, and the half gear 28 is rotated between the first passage 29 and the second passage 30. Between the two passages 30, the bottom surface of the ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com