A domestic waste disposal device

A treatment device and domestic waste technology, applied in the direction of grain treatment, transportation and packaging, manufacturing tools, etc., can solve the problem of no compaction treatment, etc., and achieve the effect of easy transshipment treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

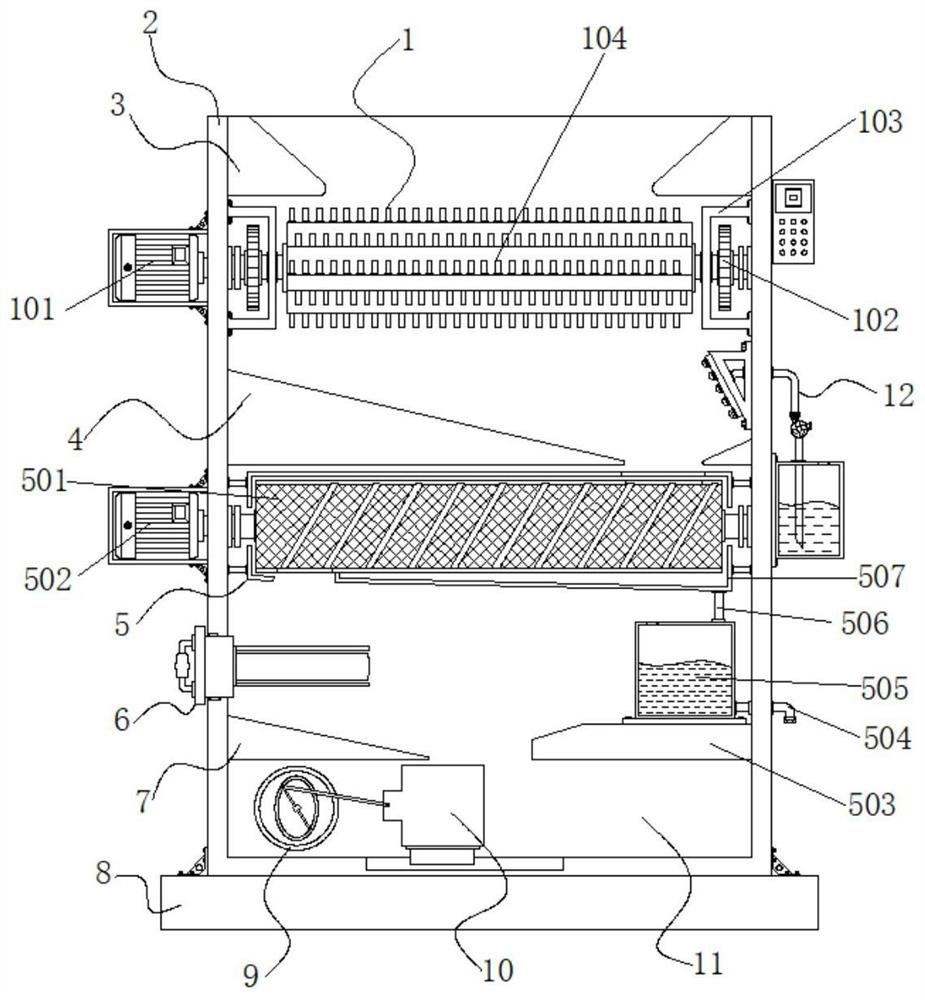

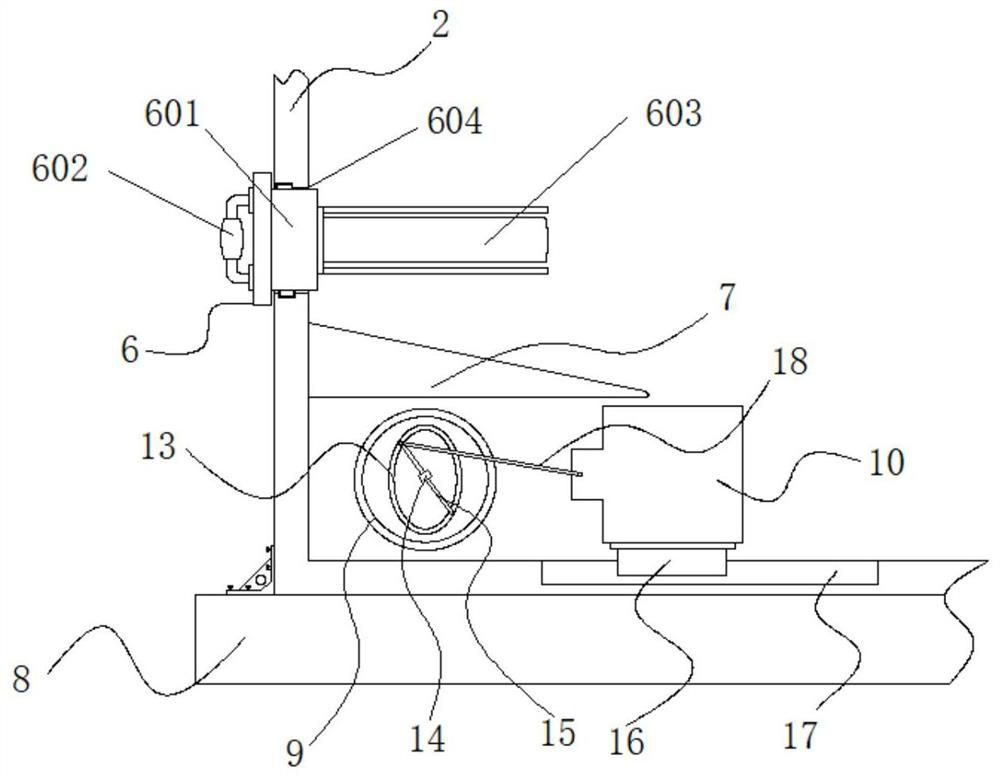

[0035] Example 1: See Figure 1-6 , a domestic waste treatment device, comprising a base 8, the top of the base 8 is fixedly connected with a frame body 2, the top inside the frame body 2 is provided with a first material guide block 3, and the top ends of the inside of the frame body 2 are provided with There is a crushing mechanism 1, a second material guide block 4 is arranged inside the bottom frame body 2 of the crushing mechanism 1, and a dehydration mechanism 5 is arranged at the middle position inside the bottom frame body 2 of the second material guide block 4, and the outer side of the frame body 2 A spray mechanism 12 is provided at the middle position of the dehydration mechanism 5, and a magnetic structure 6 is provided on one side inside the bottom frame body 2 of the dehydration mechanism 6. A third material guide block 7 is arranged inside the bottom frame body 2 of the magnetic structure 6, and a third material guide block 7 is arranged inside the frame body 2. ...

Embodiment 2

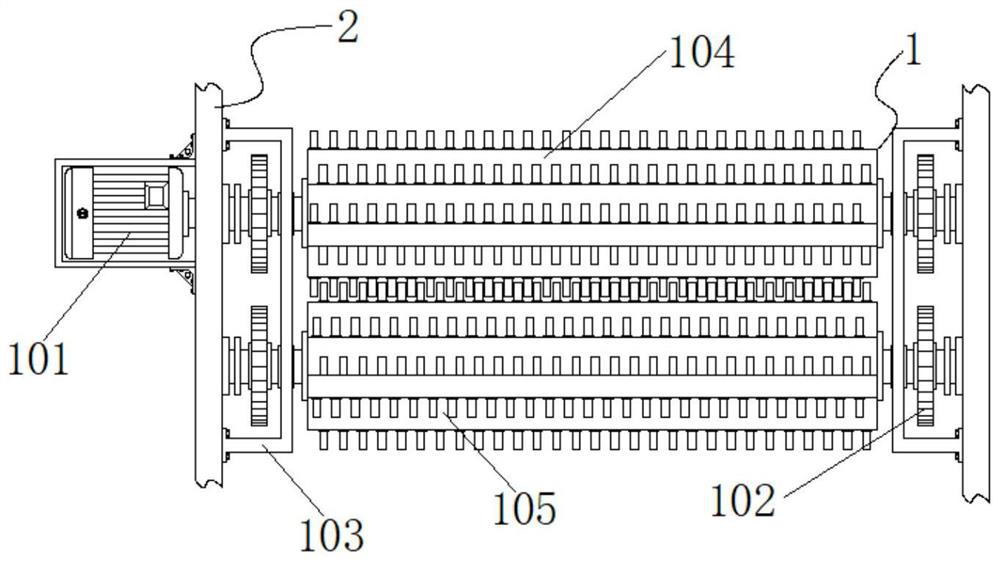

[0038] Embodiment 2: The crushing mechanism 1 is composed of a first driving motor 101, a gear 102, a cover 103, a first crushing roller 104 and a second crushing roller 105. The model of the first driving motor 101 can be Y90L-2, the first The crushing roller 104 is arranged on the top inside the frame body 2, and the two ends of the first crushing roller 104 are fixedly connected with the top ends on both sides inside the frame body 2, and one end of the first crushing roller 104 is provided with a second crushing roller 105, and the first crushing roller 104 Both ends of the roller 104 and the second crushing roller 105 are provided with a gear 102, the outside of the gear 102 is provided with a cover 103, one side of the cover 103 is fixedly connected with the frame body 2, and the first drive motor 101 is arranged on the frame body 2 At the top of the outer side, the first drive motor 101 is fixedly connected to one end of the first crushing roller 104 through a coupling, ...

Embodiment 3

[0040] Embodiment 3: The dehydration mechanism 5 is composed of a drum 501, a second drive motor 502, a support seat 503, an outlet pipe 504, a collection box 505, a first conduit 506 and an outer cylinder 507. The model of the second drive motor 502 can be Y90S -2, the second drive motor 502 is arranged at the middle position on the outer side of the frame body 2, the roller 501 is arranged at the middle position inside the frame body 2, and the output end of the roller 501 is connected to the second drive motor 502 through a coupling One end is fixedly connected, and an outer cylinder 507 is arranged on the outside of the drum 501, and both sides of the outer cylinder 507 are fixedly connected to the middle positions of both sides inside the frame body 2, and the support seat 503 is fixedly connected to the bottom end of one side inside the frame body 2 A collection box 505 is fixedly connected to the top of the support base 503, a water outlet pipe 504 is fixedly connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com