Novel tunnel waterproof layer laying trolley and use method thereof

A technology for laying trolleys and waterproof layers, which is applied in tunnels, tunnel linings, mining equipment, etc. It can solve the problems of poor laying quality, single and backward functions, and large number of labor, so as to achieve the effect of easy procurement and improved engineering practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further introduced below in conjunction with the accompanying drawings.

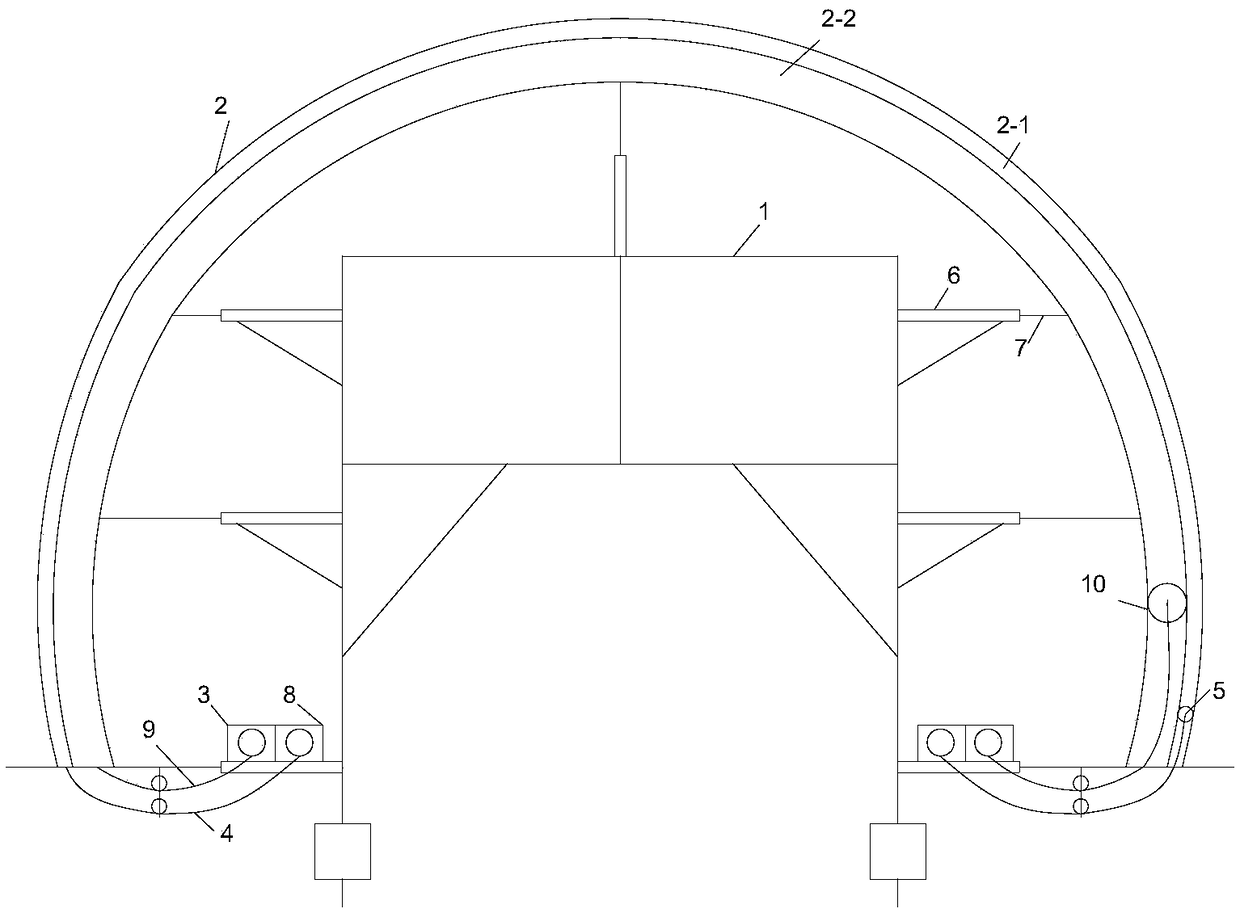

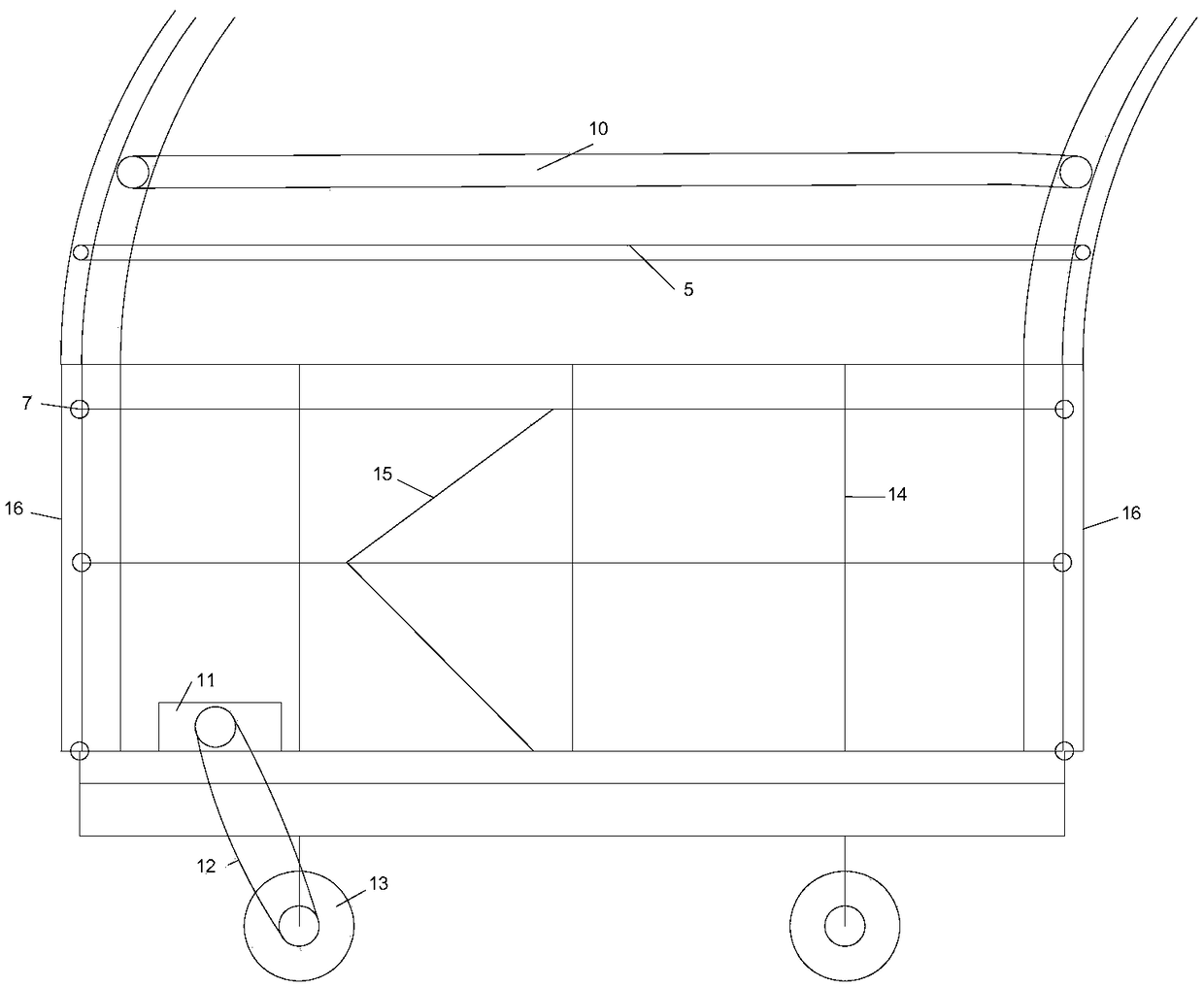

[0034] Such as figure 1 As shown, the trolley for laying a new type of tunnel waterproof layer in the present invention includes a main body structure of the trolley and an accessory device. , flattening device and self-propelled device;

[0035] Described arch frame 16 is arranged on the two ends of vehicle body, and arc groove 2 is all arranged on two arch frame 16, and described arc groove 2 comprises inner groove 2-2 and outer groove 2-1, two A slidable roller 10 is inserted between the inner grooves 2-2; a slidable clamping rod 5 is inserted between the two outer grooves 2-1, and the clamping rod 5 is used to connect the waterproof layer;

[0036] In a preferred embodiment of the present invention, both ends of the clamp bar 5 and the two ends of the cylinder 10 are provided with spheres, and the diameter of the sphere is greater than the diameter of the clamp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com