Zero-power-consumption medical equipment production sewage and wastewater treatment method

A technology of medical equipment and treatment method, which is applied in the field of sewage and wastewater treatment in the production of zero-power-consumption medical equipment, can solve the problems of large loss, high electricity cost, high production cost, etc., and achieve the effect of zero-power-consumption work and realization of power-consumption work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

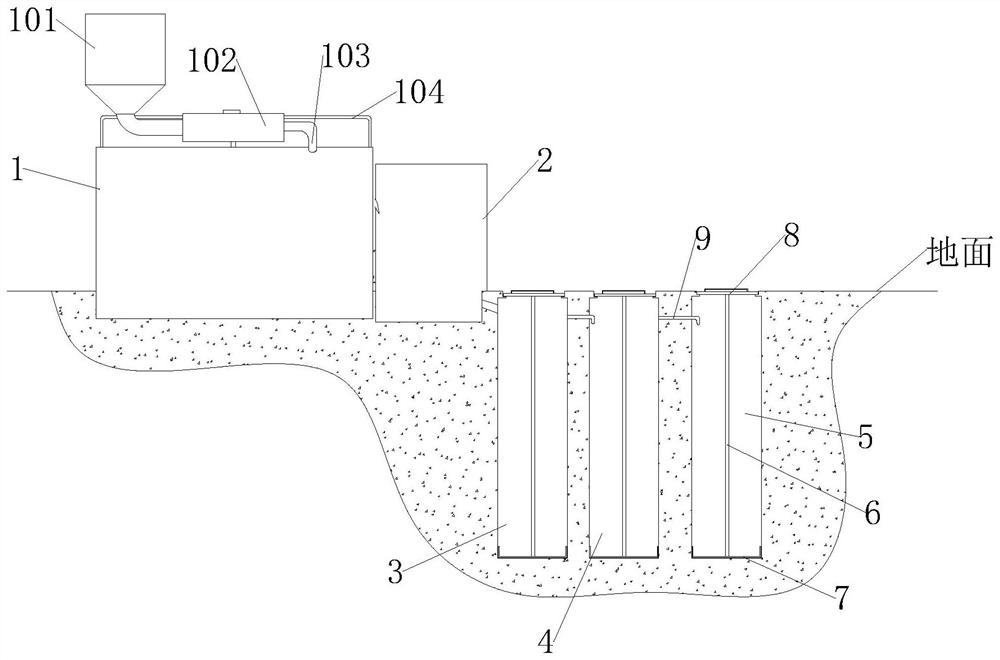

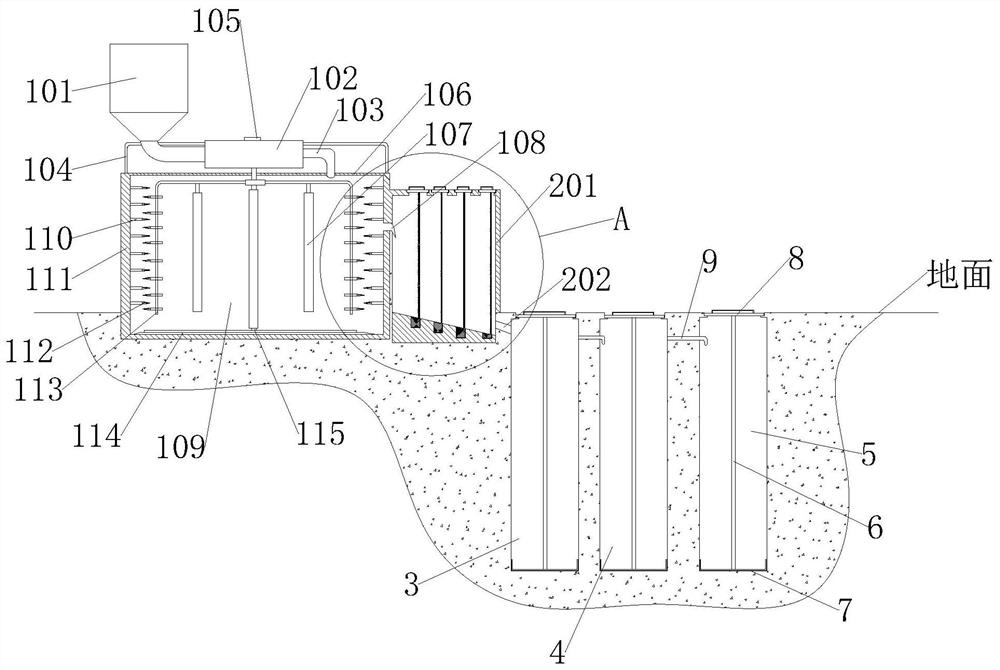

[0045] see Figure 1-9 It is a schematic diagram of the overall structure of a zero-power-consumption medical equipment production wastewater treatment method;

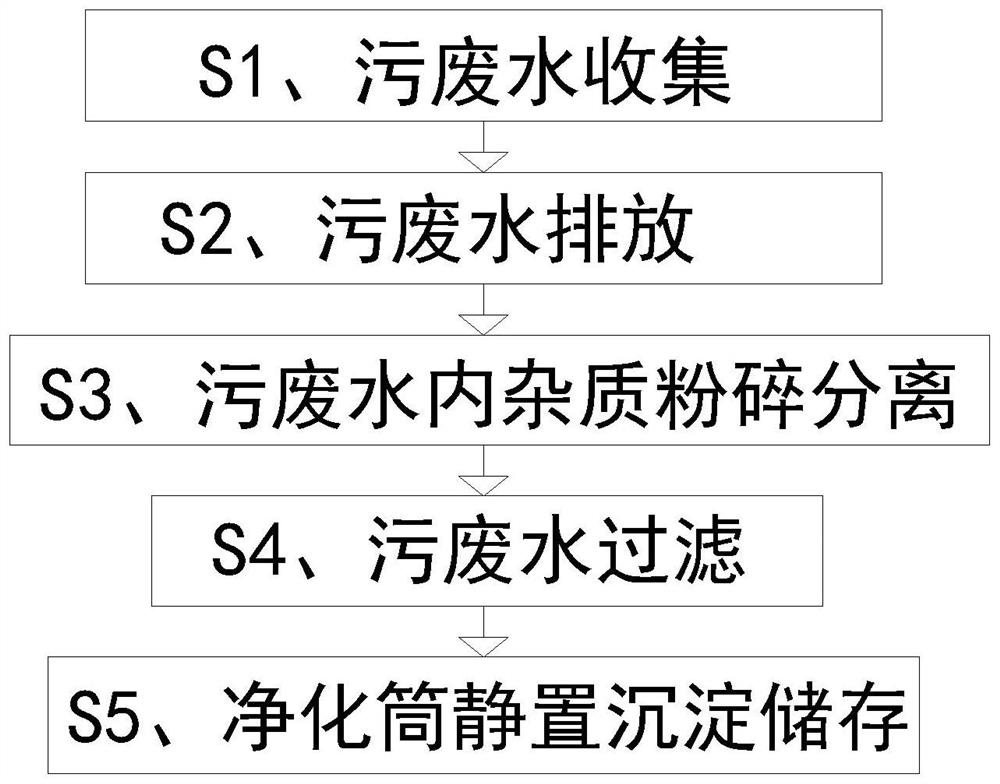

[0046] A zero-power-consumption medical equipment production sewage treatment method, comprising the following steps:

[0047] S1. Sewage and waste water collection: collect the sewage and waste water generated during the production of medical equipment in the waste water collection tank 101;

[0048] S2, discharge of sewage and waste water: use a sewage discharge pipe 103 to uniformly discharge the sewage and waste water in the sewage and waste water collection cylinder 101 for the sewage and waste water collected in step S1, and use the potential energy generated when the sewage and waste water is discharged in the sewage discharge pipe 103 to promote The impeller rotates to drive the sewage crushing device 1 to work;

[0049] S3. Pulverization and separation of impurities in sewage and wastewater: separate the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com