Plug valve sealing grinding machine

A grinding machine and cock valve technology, which is applied in the direction of grinding machine tools, grinding devices, metal processing equipment, etc., can solve the problems of unbalanced grinding force, affecting machining accuracy, and poor taper fit, etc., to achieve balanced grinding force and machining accuracy The effect of high and small adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

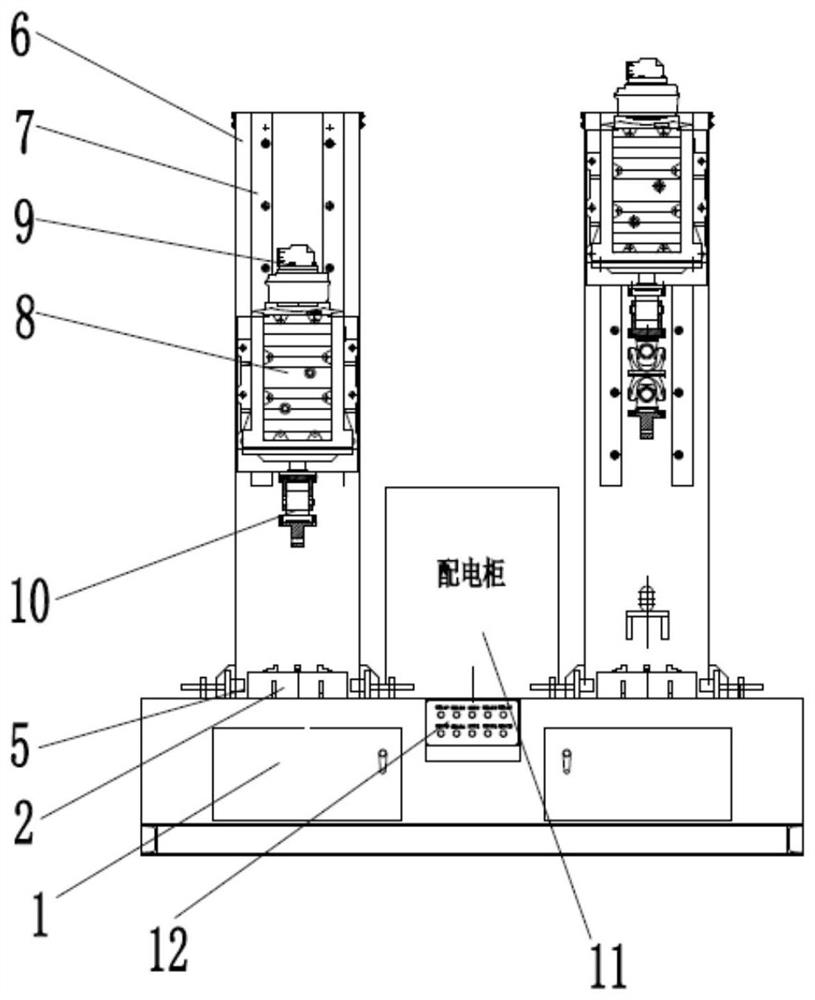

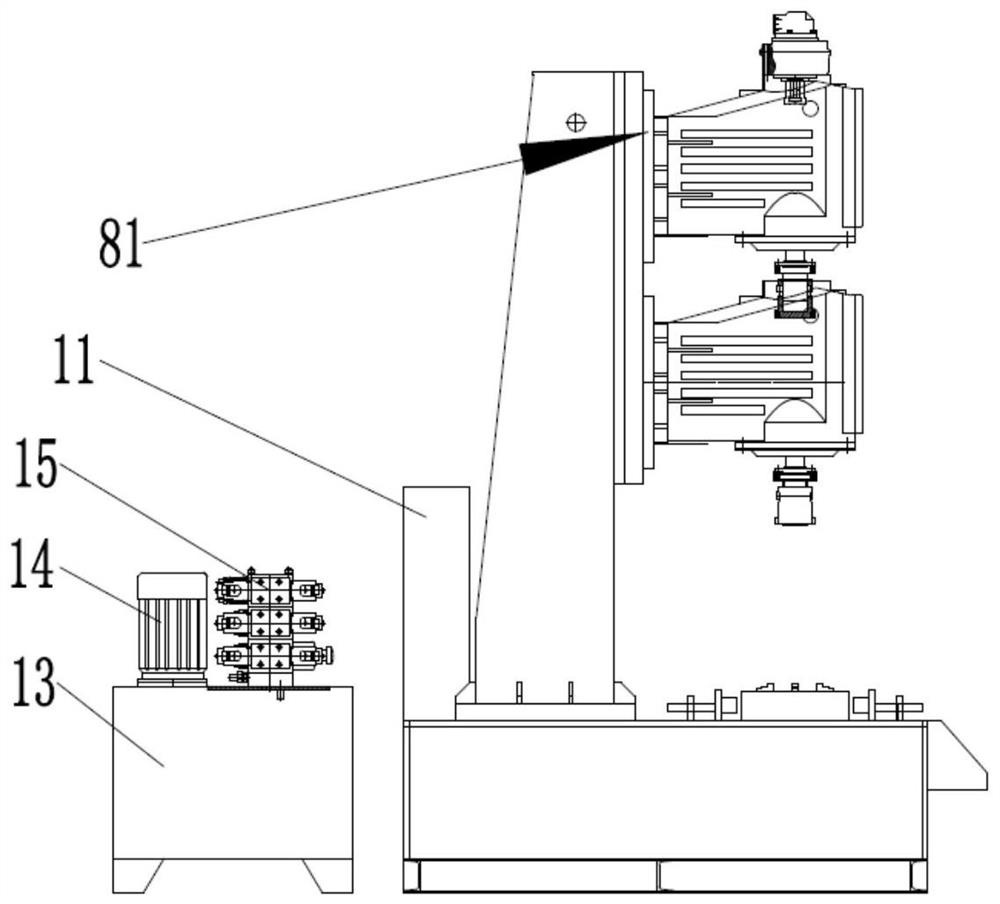

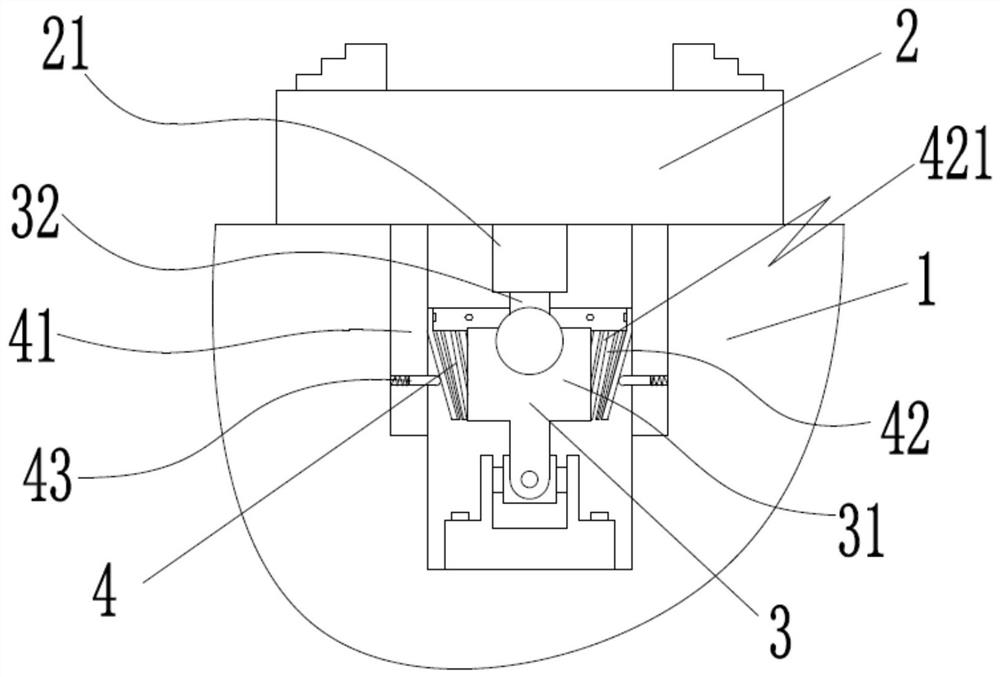

[0025]referenceFigure 1 to 5Further explanation of this application, such asfigure 1 withfigure 2 A plug valve sealing mill, including a table 1 having at least one column 6, and the back plate 87 of the gearbox 8 is slid in a sliding rail 7 located on the column 6, Further, the gearbox 8 is connected between the gearbox 8 between the gearbox 8 to be lively disposed on the column 6, and the table 1 is provided with a unit 3, placed in the The fixing holder 2 for the fixing valve seat is driven on the working table 1 and the unive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com